Anode foil etching process for aluminum electrolytic capacitor

A technology for aluminum electrolytic capacitors and anode foils, which is applied in the direction of electrolytic capacitors, electrolytic capacitor manufacturing, capacitors, etc., can solve the problems of tunnel hole length and poor uniformity of hole diameter, deterioration of mechanical properties of corroded foil, unfavorable electrode foil capacity, etc., to achieve Improve capacity and bending resistance, reduce lateral branch holes, and improve corrosion pit morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] (1) Pre-treatment: use high-purity aluminum foil produced by Dongyang Guangguang, with an aluminum content of ≥99.99% and a cubic texture of >95%. 3 PO 4 After soaking in the solution for 60s, rinse with deionized water.

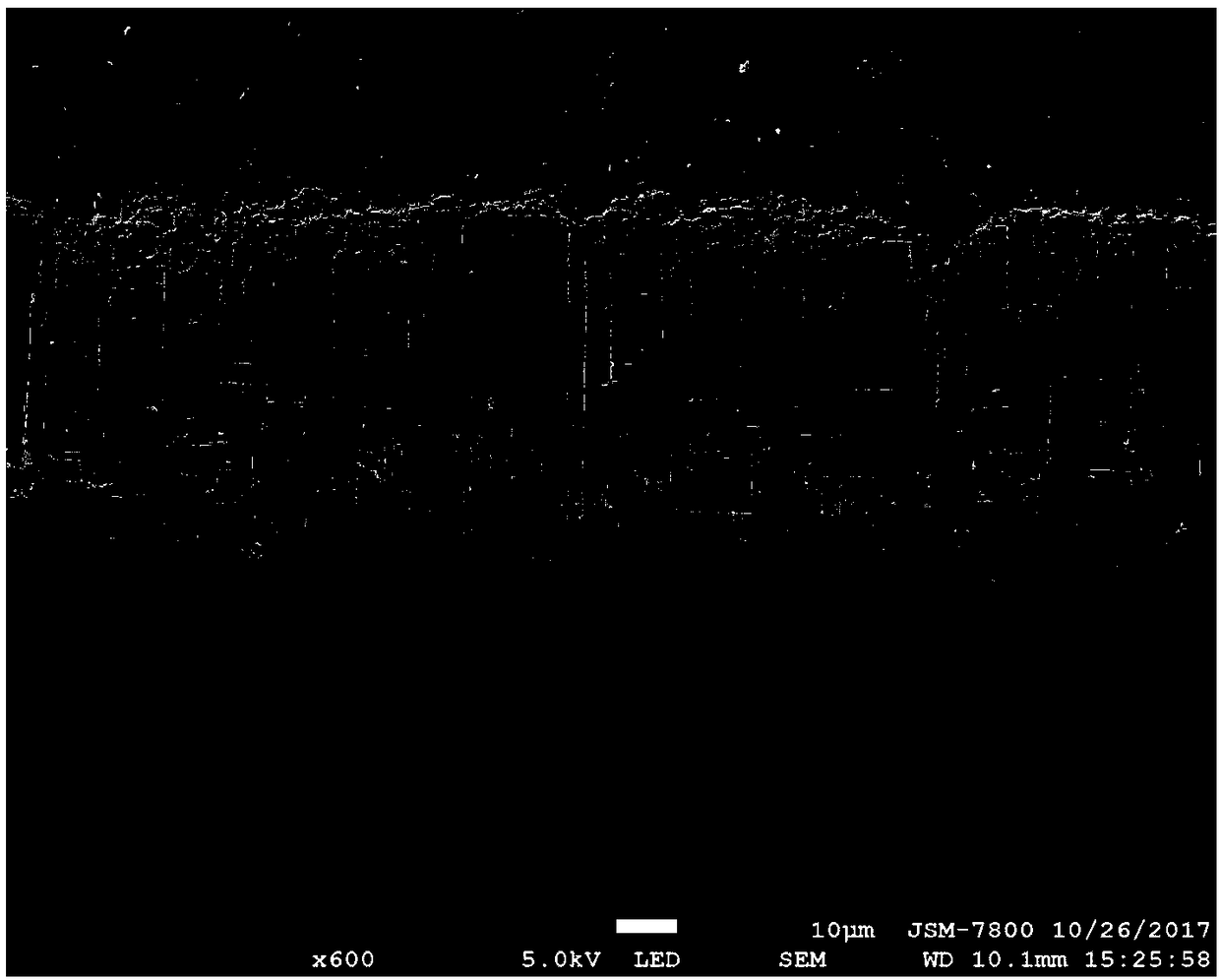

[0054] (2) First-order porosity corrosion: the above-mentioned pretreated aluminum foil is heated in 3wt%HCl+30wt%H 2 SO 4 +20mMEDTA-2Na in aqueous solution for primary corrosion, corrosion time is 60s, current density is 0.6A / cm 2 , the temperature is 70°C, after the corrosion is completed, it is cleaned with deionized water to obtain a first-grade corroded foil with pores;

[0055] (3) Secondary hole-expanding corrosion: the first-level hole-corroding foil is exposed to 7wt% HNO 3 Corrosion in the solution for 500s, the current density is 0.15 A / cm 2 , the temperature is 70°C, and after the etching is completed, it is cleaned with deionized water to obtain a secondary hole expansion corrosion foil;

[0056] (4) post-corrosion treatment: immers...

Embodiment 2

[0058] (1) Pre-treatment: use high-purity aluminum foil produced by Dongyang Guangguang, with an aluminum content of ≥99.99% and a cubic texture of >95%. 3 PO 4 After soaking in the solution for 60s, rinse with deionized water.

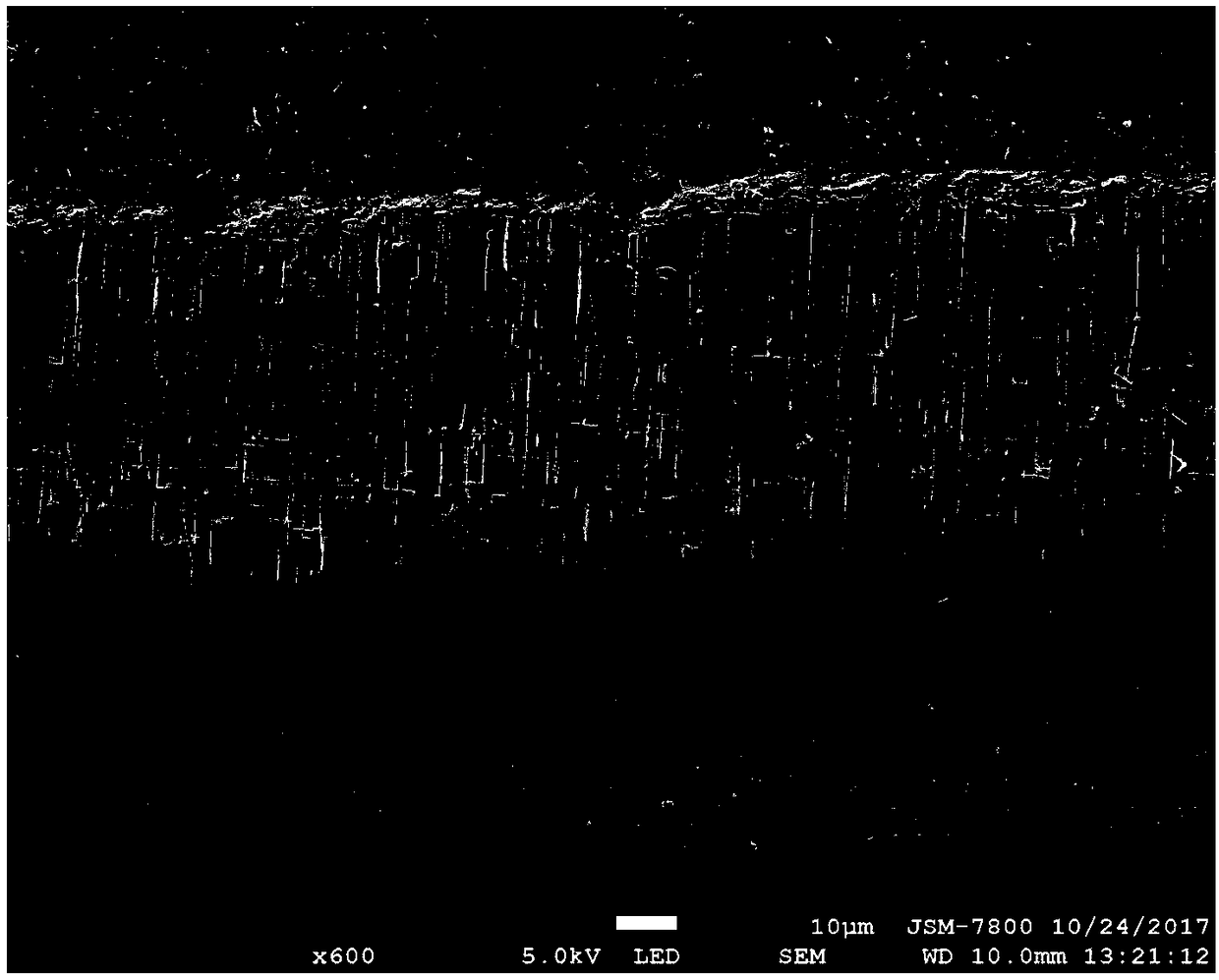

[0059] (2) First-order porosity corrosion: the above-mentioned pretreated aluminum foil is heated in 3wt%HCl+30wt%H 2 SO 4 +40mMEDTA-2Na aqueous solution for primary corrosion, corrosion time is 60s, current density is 0.6A / cm 2 , the temperature is 70°C, after the corrosion is completed, it is cleaned with deionized water to obtain a first-grade corroded foil with pores;

[0060] (3) Secondary hole-expanding corrosion: the first-level hole-corroding foil is exposed to 7wt% HNO 3 Corrosion in the solution for 500s, the current density is 0.15A / cm 2 , the temperature is 70°C, and after the etching is completed, it is cleaned with deionized water to obtain a secondary hole expansion corrosion foil;

[0061] (4) post-corrosion treatment: immerse th...

Embodiment 3

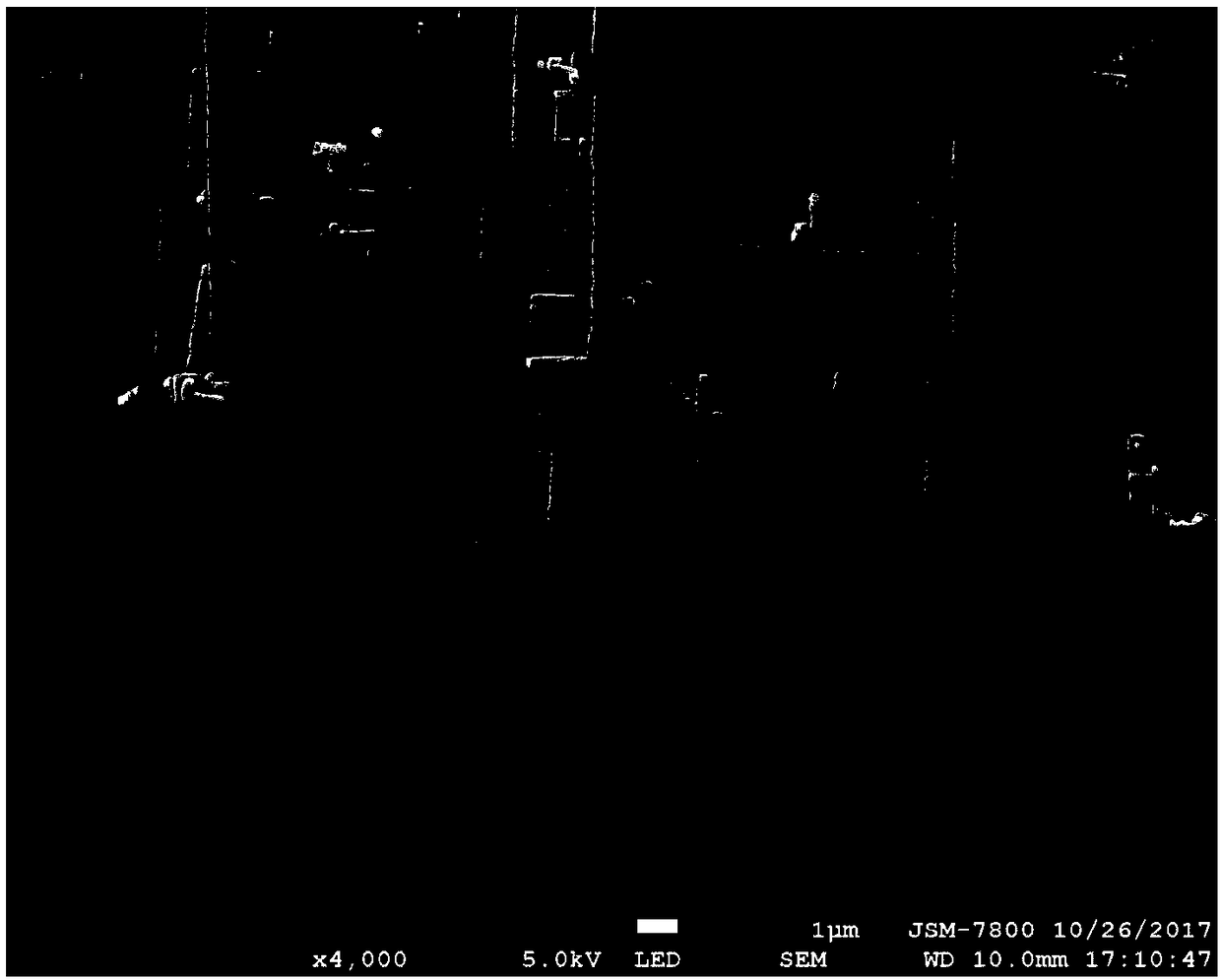

[0063] (1) Pre-treatment: use high-purity aluminum foil produced by Dongyang Guangguang, with an aluminum content of ≥99.99% and a cubic texture of >95%. 3 PO 4 After soaking in the solution for 60s, rinse with deionized water.

[0064] (2) First-order porosity corrosion: the above-mentioned pretreated aluminum foil is heated in 3wt%HCl+30wt%H 2 SO 4 Carry out primary corrosion in +36mM gluconic acid aqueous solution, the corrosion time is 60s, and the current density is 0.6A / cm 2 , the temperature is 70°C, after the corrosion is completed, it is cleaned with deionized water to obtain a first-grade corroded foil with pores;

[0065] (3) Secondary hole-expanding corrosion: the first-level hole-corroding foil is exposed to 7wt% HNO 3 Corrosion in the solution for 500s, the current density is 0.15 A / cm 2 , the temperature is 70°C, and after the etching is completed, it is cleaned with deionized water to obtain a secondary hole expansion corrosion foil;

[0066] (4) post-cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com