Carbon nanotube and tin dioxide modified titanium carbide lithium ion battery negative electrode material with three-dimensional 'plane-line-plane' structure and preparation method thereof

A technology of carbon nanotubes and tin dioxide, applied in battery electrodes, secondary batteries, structural parts, etc., to achieve the effect of improving electrochemical performance, excellent electrochemical performance, and improving surface-to-surface contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

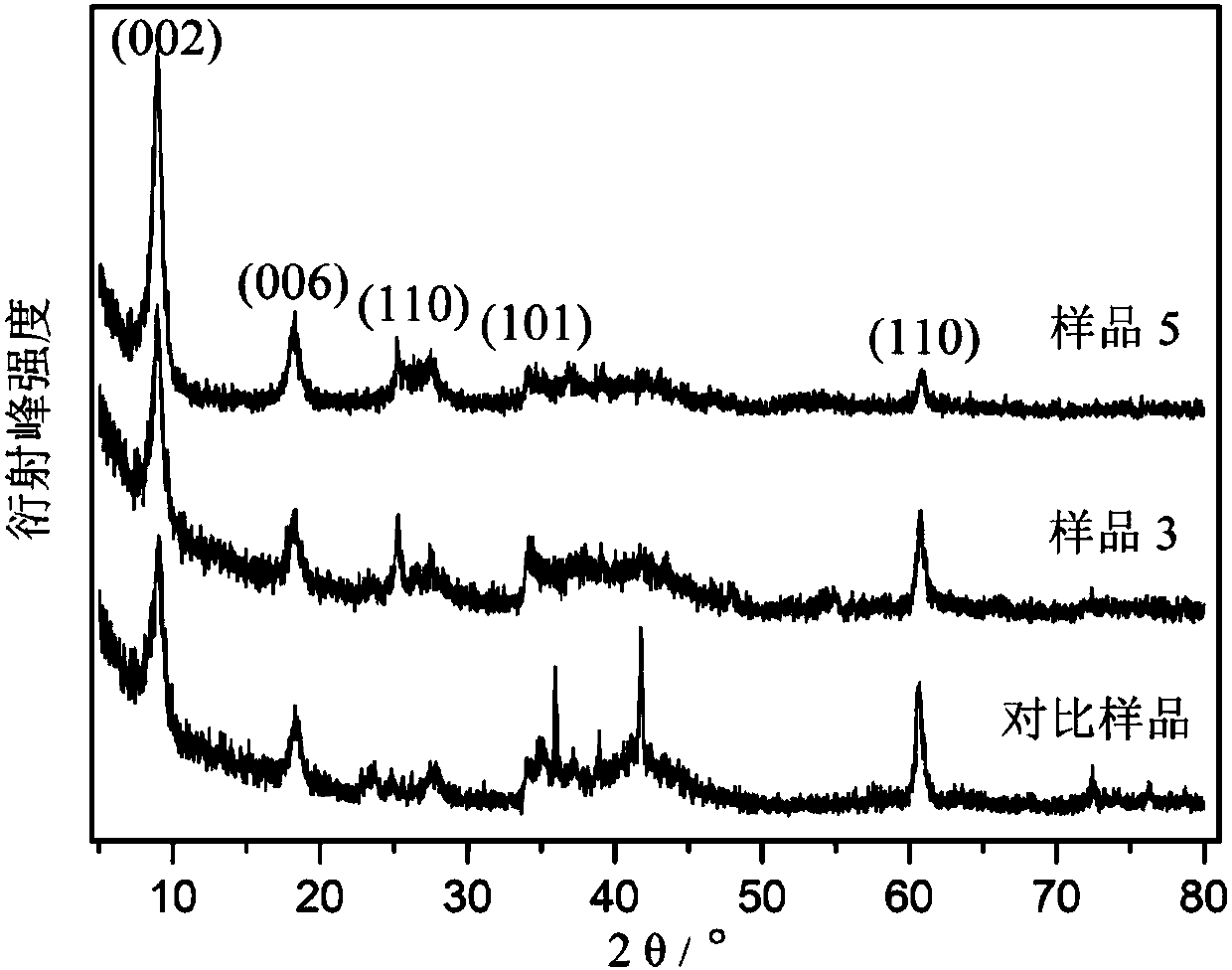

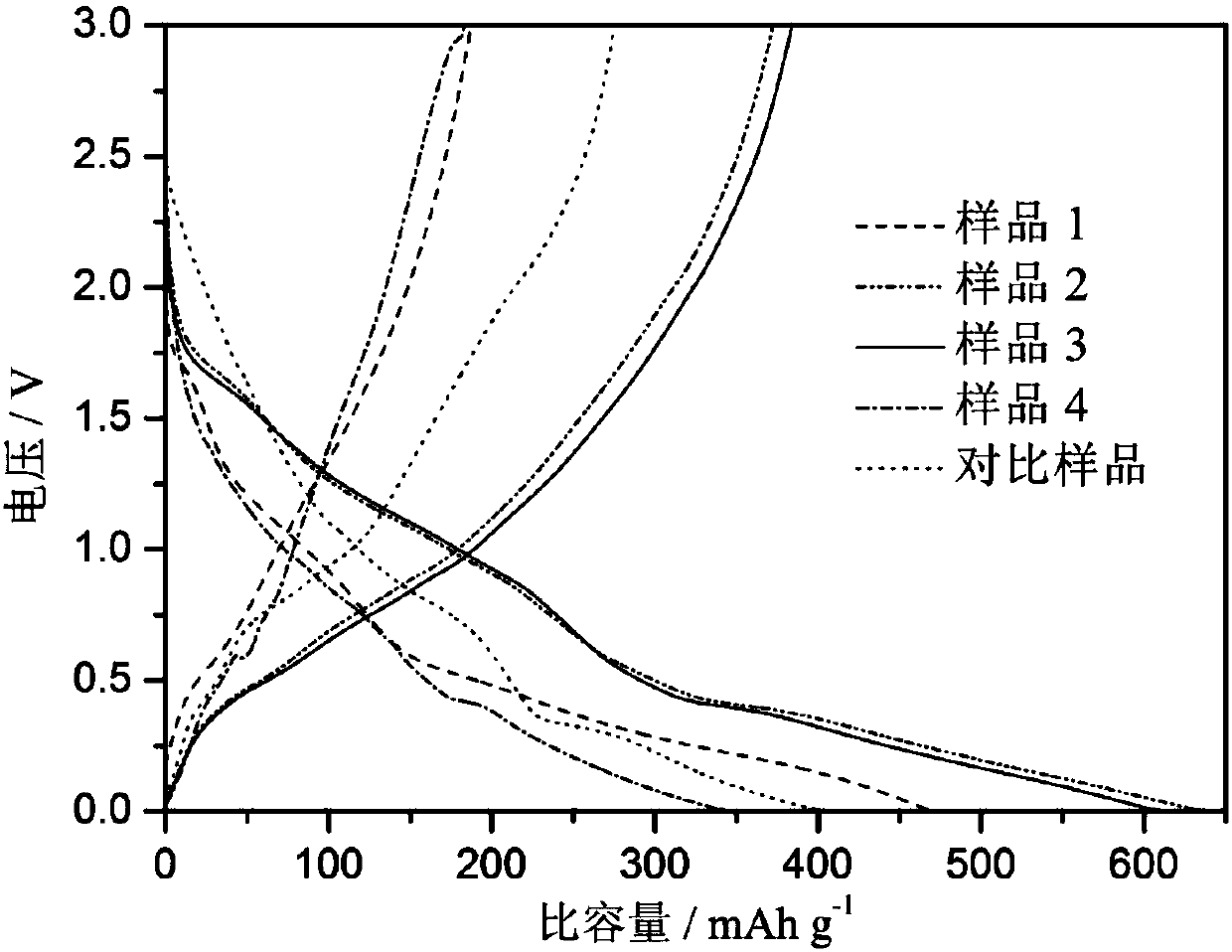

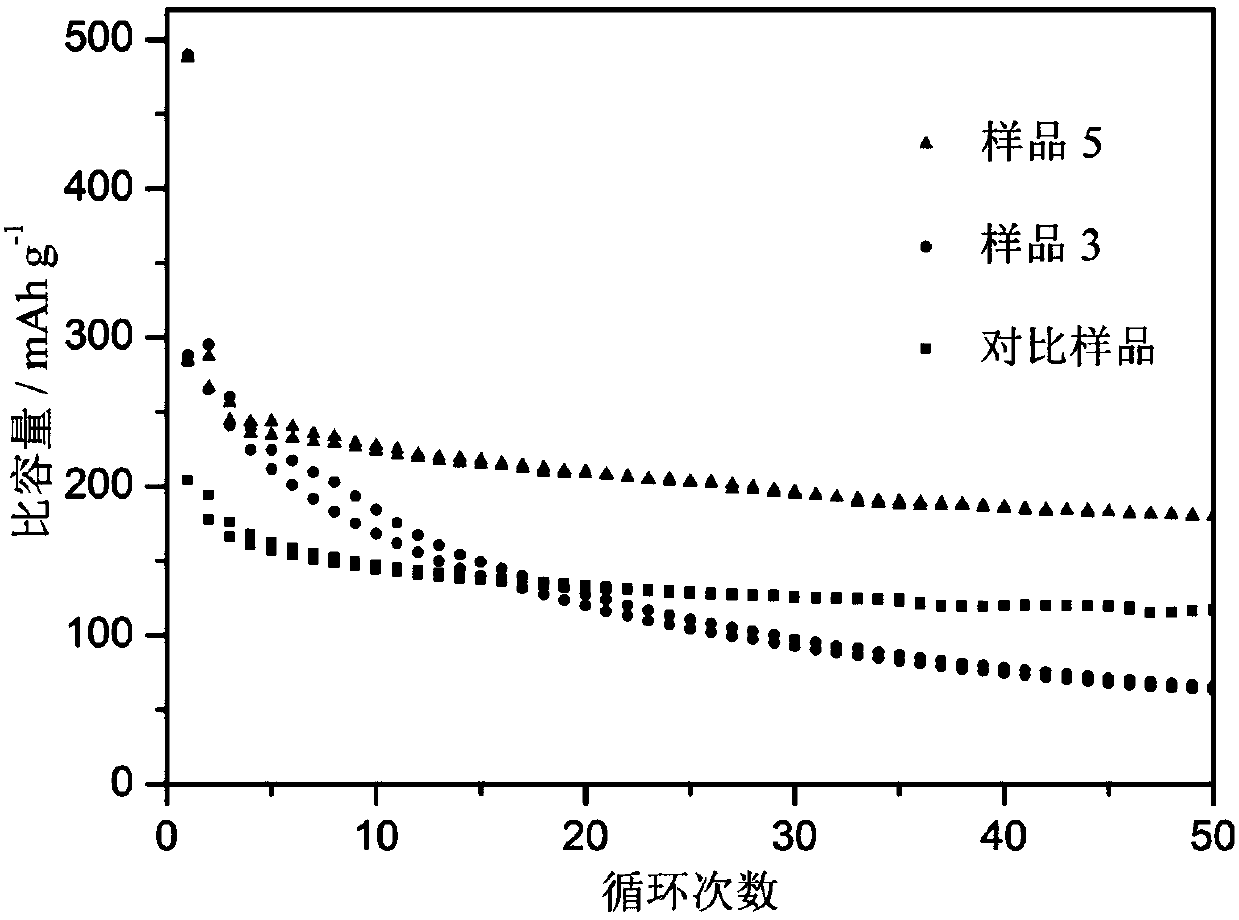

Embodiment 1

[0040] 1 g Ti 3 AlC 2 The powder was dispersed into 20 ml of hydrofluoric acid solution with a mass fraction of 50%, and stood at room temperature for 24 hours, and then the precipitate was centrifuged with distilled water for 5 times until the pH of the solution was 5. The precipitate was put into a vacuum drying oven and dried at 80° C. for 12 hours to obtain a black powder. 0.113 g of SnCl 2 Dissolve in 25 mL of distilled water, then add the resulting black powder to SnCl 2 The solution was stirred at room temperature for 3 hours, and ultrasonic oscillation was continued for 30 minutes to obtain a black suspension. Put the black suspension into a reaction kettle with a polytetrafluoroethylene liner, then put the reaction kettle into an oven, and keep the temperature at 130°C for 5 hours. After natural cooling, wash the precipitate in the reaction kettle with distilled water three times, put the precipitate in a drying oven, and dry it at 80°C for 12 hours, then grind it...

Embodiment 2

[0043] 1 g Ti 3 AlC 2 The powder was dispersed into 20 ml of hydrofluoric acid solution with a mass fraction of 50%, and stood at room temperature for 24 hours, and then the precipitate was centrifuged with distilled water for 5 times until the pH of the solution was 5. The precipitate was put into a vacuum drying oven and dried at 80° C. for 12 hours to obtain a black powder. 0.564 g of SnCl 2 Dissolve in 25 mL of distilled water, then add the resulting black powder to SnCl 2 The solution was stirred at room temperature for 3 hours, and ultrasonic oscillation was continued for 30 minutes to obtain a black suspension. Put the black suspension into a reaction kettle with a polytetrafluoroethylene liner, then put the reaction kettle into an oven, and keep the temperature at 130°C for 5 hours. After natural cooling, wash the precipitate in the reaction kettle with distilled water three times, put the precipitate in a drying oven, and dry it at 80°C for 12 hours, then grind it...

Embodiment 3

[0046] 1 g Ti 3 AlC 2The powder was dispersed into 20 ml of hydrofluoric acid solution with a mass fraction of 50%, and stood at room temperature for 24 hours, and then the precipitate was centrifuged with distilled water for 5 times until the pH of the solution was 5. The precipitate was put into a vacuum drying oven and dried at 80° C. for 12 hours to obtain a black powder. 2.821 g of SnCl 2 Dissolve in 25 mL of distilled water, then add the resulting black powder to SnCl 2 The solution was stirred at room temperature for 3 hours, and ultrasonic oscillation was continued for 30 minutes to obtain a black suspension. Put the black suspension into a reaction kettle with a polytetrafluoroethylene liner, then put the reaction kettle into an oven, and keep the temperature at 130°C for 5 hours. After natural cooling, wash the precipitate in the reaction kettle with distilled water three times, put the precipitate in a drying oven, and dry it at 80°C for 12 hours, then grind it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com