New technique for improving paper strength by joint gelatinization of starch and pulp

A slurry concentration and slurry technology, which is applied in paper, special paper, textiles and papermaking, etc., can solve the problems of low surface strength, poor paper strength, and influence of paper strength, so as to achieve tight fiber wrapping and reduce starch loss , Improve the effect of strength index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

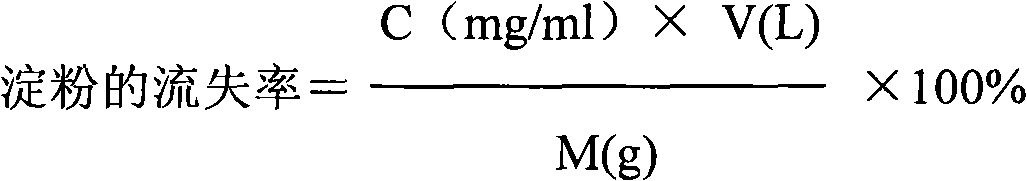

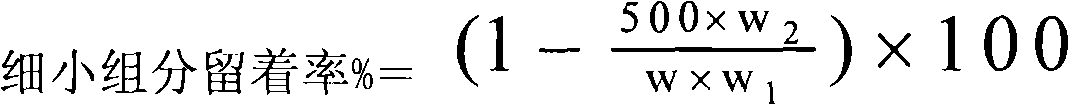

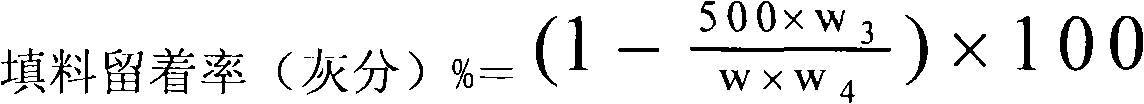

[0052]10g dry mechanical pulp, use oxidized starch, the amount of starch is calculated based on the dry weight of the pulp, the concentration of the pulp is heated to 15%, the temperature is 100°C, and the time is 60min. After heated and gelatinized, it is extruded and concentrated, and the slurry concentration reaches 43%. The specific enhancement effect and starch loss are shown in the table below:

[0053] Quantitative

Embodiment 2

[0055] According to the ratio of 10% coniferous pulp, 10% mechanical pulp, and 80% broad-leaf pulp, the dry-dried slurry is 10g, and oxidized starch is used. The amount of starch is calculated based on the dry mass of the slurry. The concentration of the heated slurry is 15%. at 100°C for 60 minutes. After heated and gelatinized, it is extruded and concentrated, and the slurry concentration reaches 38%. The specific enhancement effect and starch loss are shown in the table below:

[0056] Quantitative

Embodiment 3

[0059] Waste paper pulp fiber dry 20g, the amount of oxidized starch 0%, 5%, 10%, 15%, 20%, 25%, squeeze concentrated to a slurry concentration of 38%, and heat at 100 ° C for 30 min to gelatinize. See the table below for enhancements:

[0060] Starch dosage

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com