Rice cooking control method for pressure electric cooker

A control method and rice cooker technology, which are applied in electrical program control, program control in sequence/logic controllers, cooking utensils, etc., can solve the problems of starch gelatinization, unripe rice, affecting the texture of rice, etc. The effect of sandwiching raw, good rice texture, and meeting the needs of starch gelatinization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

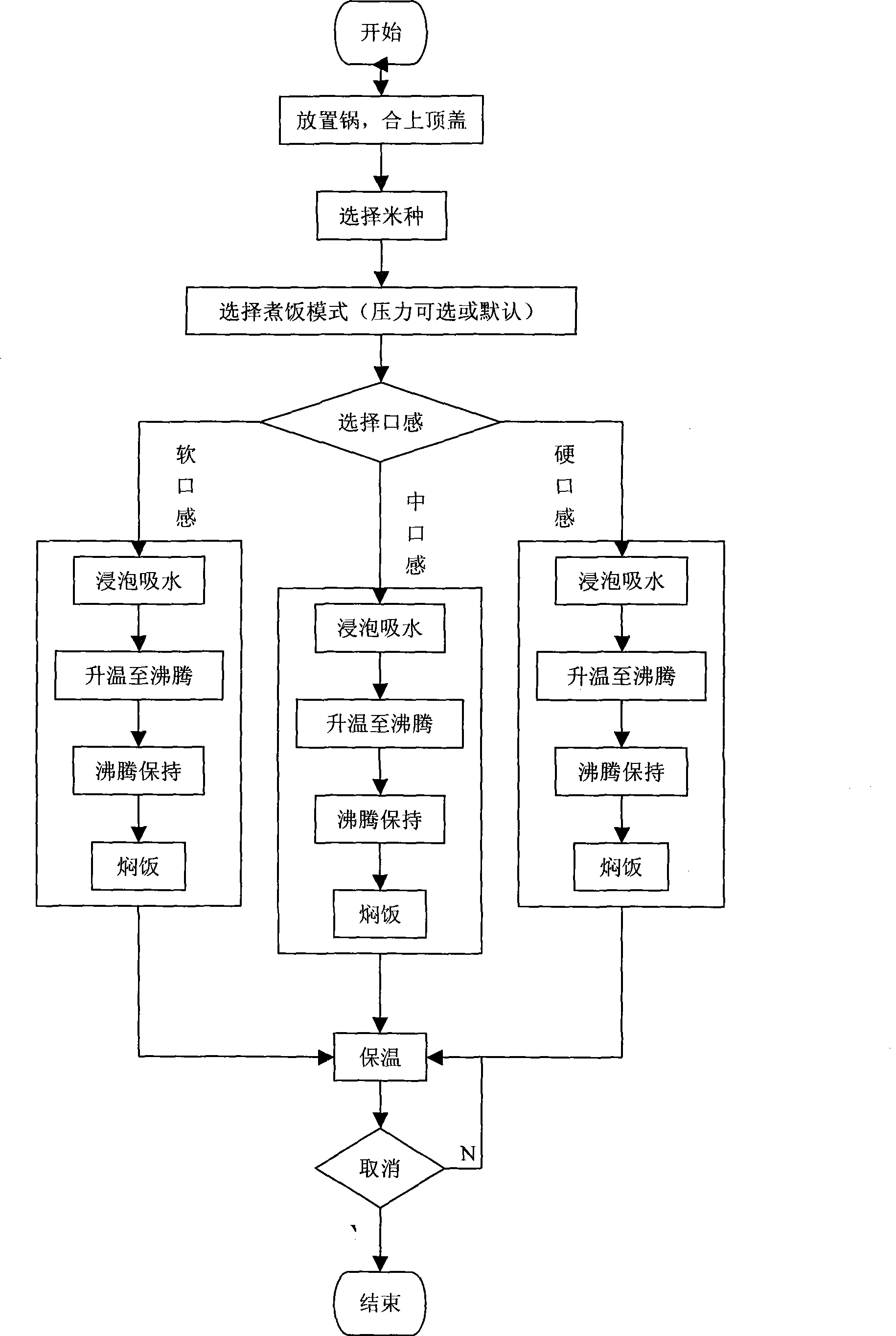

[0028] refer to figure 1 ~Fig. 6, a kind of pressure cooker rice cooking control method, comprises the following steps:

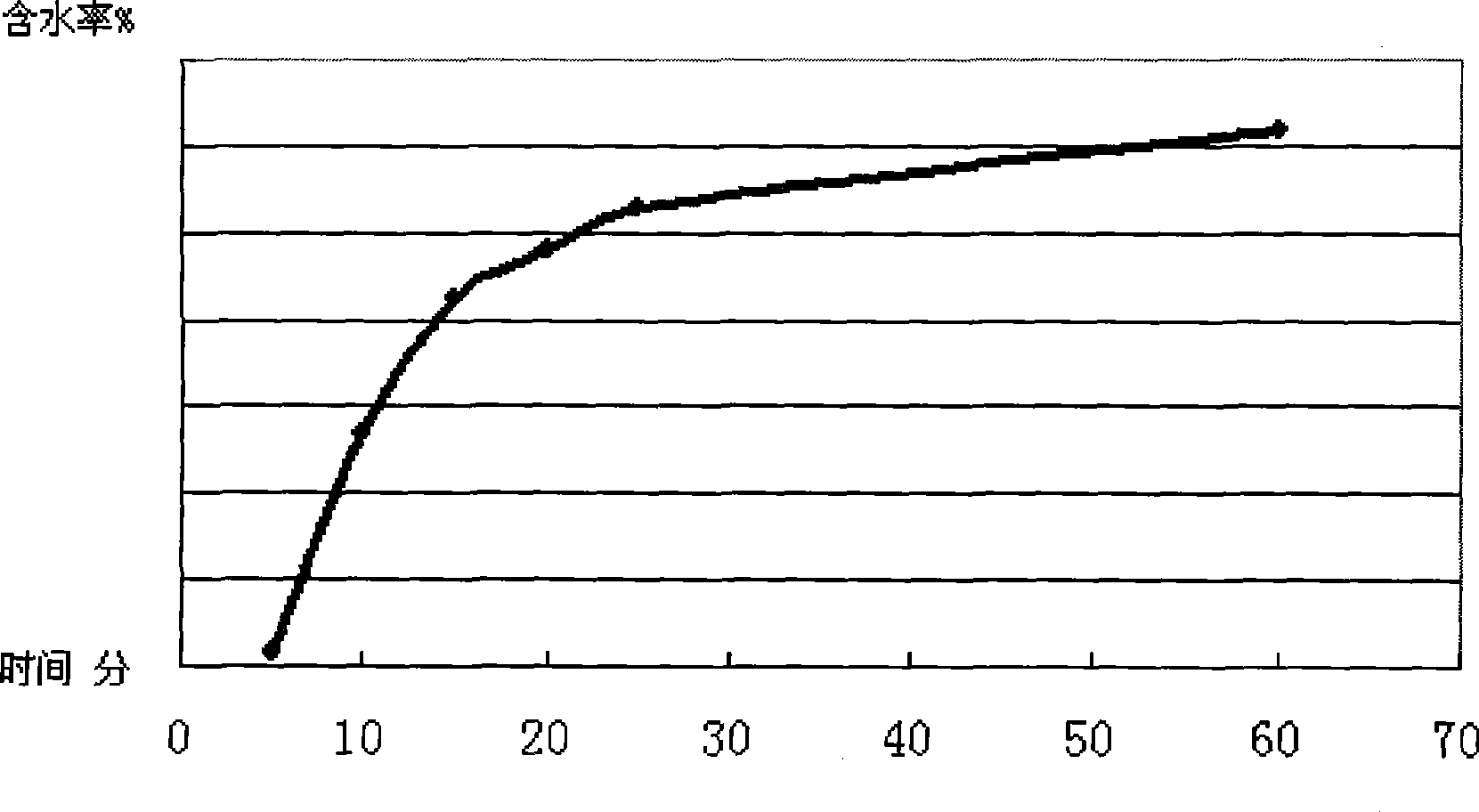

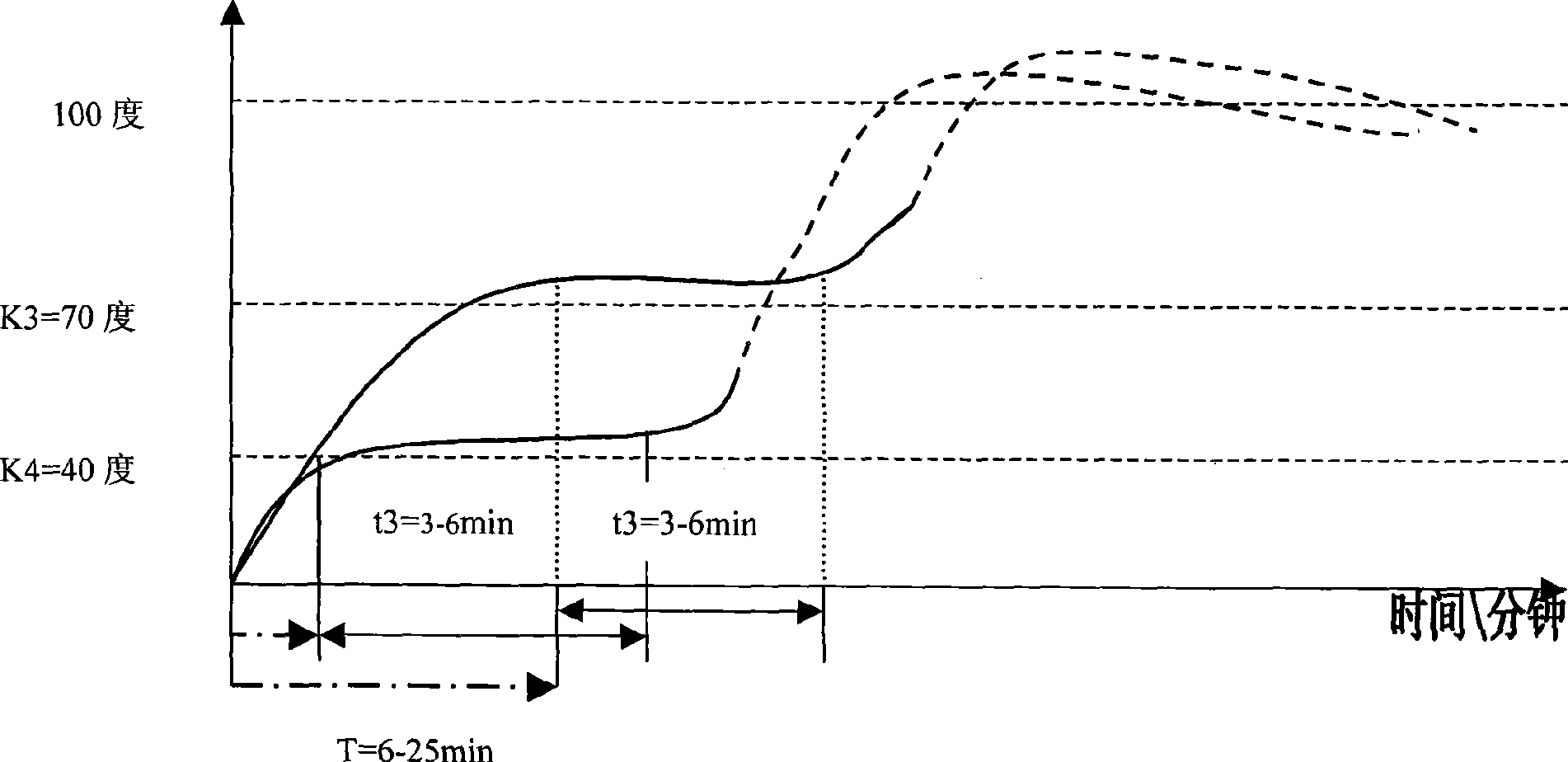

[0029] (1) Determine the soaking time t and the preset soaking temperature K according to different rice types, mouthfeel and different pressures, wherein, t=3-8min, K=50-80°C;

[0030] (2), start the heater, after the time T, T=6-25min, until the measured soaking temperature reaches the preset soaking temperature K, start timing after reaching the preset soaking temperature K;

[0031] (3) After reaching the preset soaking time t, according to the set procedure, the temperature is raised to boil, and the same preset pressure P in the pot is kept boiling, and after boiling, the rice is stewed and exhausted.

[0032] In described step (1), the method for determining soaking time t and preset soaking temperature K comprises the following steps:

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com