Method for anodic oxidizing of zinc alloy

An anodizing and anodizing film technology, applied in anodizing, superimposed layer plating, metal material coating process, etc., can solve problems such as color and reliability limitations, improve product competitiveness, and improve appearance and texture , Improve the effect of texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

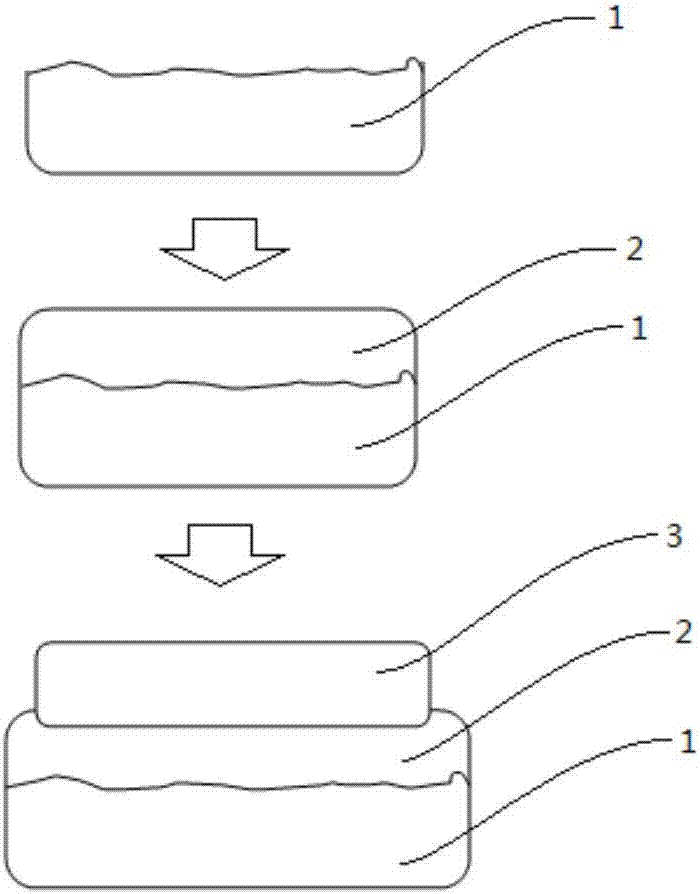

Image

Examples

Embodiment 1

[0063] 1. Prepare the first aluminum film on the surface of the zinc alloy by magnetron sputtering: use pure aluminum as the target material, and the air pressure is 8×10 -2 Pa, the deposition time is 120 seconds; the thickness of the first aluminum film is 300nm;

[0064] 2. Prepare the second aluminum film by resistance heating evaporation on the surface of the first aluminum film; the vacuum chamber pressure in the resistance heating evaporation is 8×10 -2 Pa, the deposition time is 30 seconds; the thickness of the second aluminum film is 15 μm;

[0065] 3. Pretreatment of the aluminum film;

[0066] Degreasing, water washing, alkali washing, double water washing, neutralization, water washing, chemical polishing, water washing, neutralization, and triple water washing are carried out in sequence;

[0067] 4. Anodizing:

[0068] Using sulfuric acid as the electrolyte, the concentration of sulfuric acid is 150g / L; the temperature of the anodizing tank is 15°C, and the tim...

Embodiment 2

[0073] 1. Prepare the first aluminum film on the surface of the zinc alloy by magnetron sputtering;

[0074] The magnetron sputtering coating equipment is used for coating, with pure aluminum as the target material, and the air pressure is 8×10 -2 Pa, the deposition time is 60 seconds; the thickness of the first aluminum film is 200nm;

[0075] 2. Prepare the second aluminum film by resistance heating evaporation on the surface of the first aluminum film; the vacuum chamber pressure in the resistance heating evaporation is 8×10 -2 Pa, the deposition time is 30 seconds; the thickness of the second aluminum film is 22 μm;

[0076] 3. Pretreatment of the aluminum film;

[0077] Degreasing, water washing, alkali washing, double water washing, neutralization, water washing, chemical polishing, water washing, neutralization, and triple water washing are carried out in sequence;

[0078] 4. Anodizing:

[0079] Sulfuric acid is used as the electrolyte, the concentration of sulfuri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com