Method for producing starch glue by low-temperature fast enzymatic conversion

An enzyme-converting starch and production method technology, applied in the directions of adding water repellents, paper, textiles and papermaking, etc., can solve the problems of unsatisfactory enhancement effect, low conversion efficiency, high starch consumption, shorten production time, reduce dosage, The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to overcome the shortcomings of the existing surface sizing starch, such as unsatisfactory enhancement effect, high starch consumption and low conversion efficiency, the present invention provides a low-temperature rapid enzymatic conversion starch glue production method. The conversion rate of the method is easy to control and reduces energy consumption. Consumption, reducing economic costs.

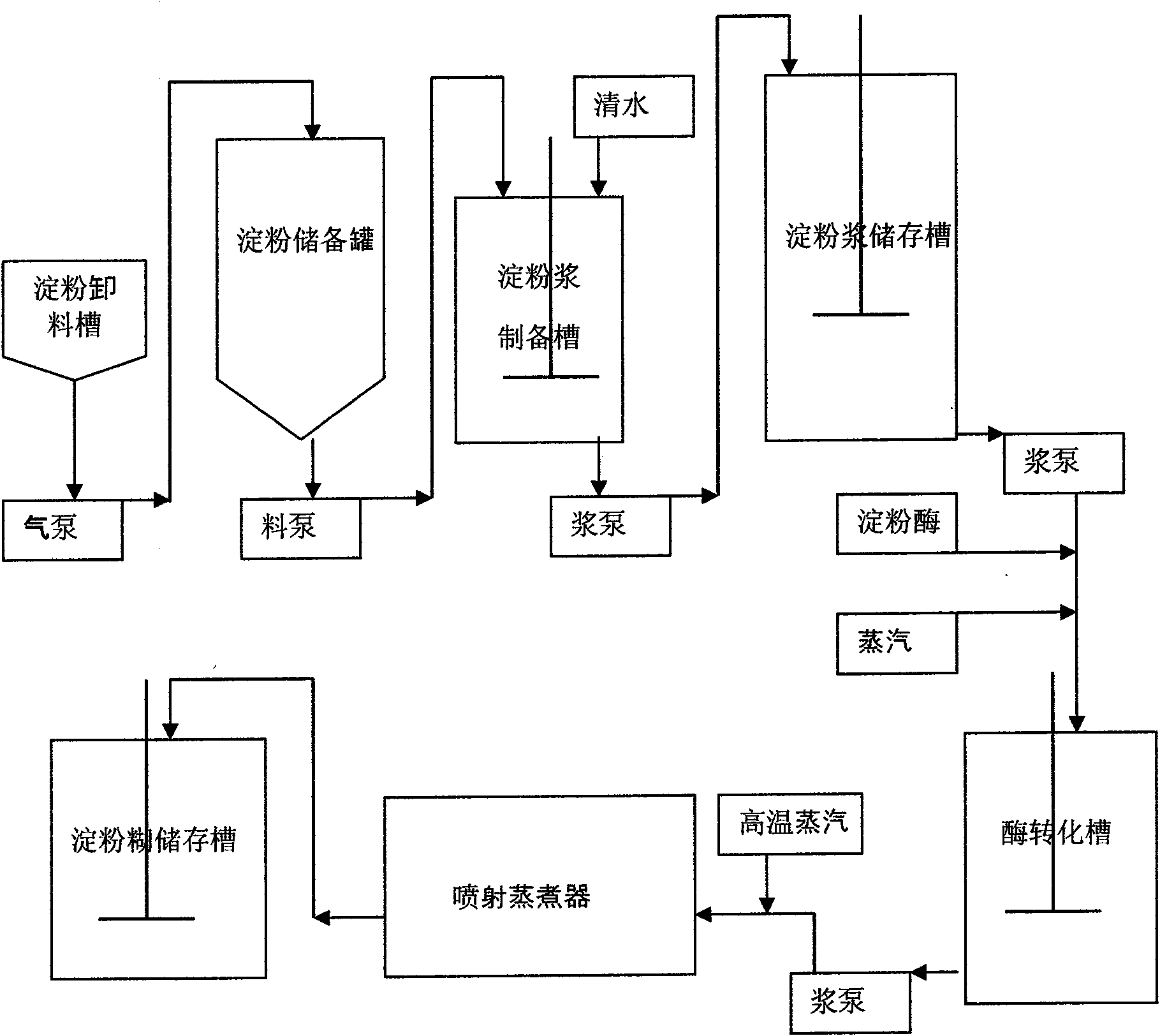

[0019] The technical solution adopted by the present invention to solve its technical problems is: the low-temperature rapid enzyme conversion starch glue production method, the process steps of the method are as follows: figure 1 :

[0020] 1) Transport the starch raw material to the starch storage tank through the unloading trough and the air pump. When preparing the starch slurry, turn on the air pump under the starch storage tank to transport the starch raw material to the starch slurry preparation tank, and prepare the starch slurry in proportion. Add clear water t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com