Method for preparing starch microspheres

A technology of starch microspheres and plant starch, which is applied to the preparation of microspheres, microcapsule preparations, medical preparations of non-active ingredients, etc., and can solve problems such as large changes in microporosity rate and affecting the slow-release effect of starch microspheres , to achieve the effect of simple preparation process and obvious sustained release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Preparation of potato starch microspheres:

[0028] 1. 10g potato starch is mixed with 4.2g water, and preparation mass percent concentration is the potato starch emulsion of 70%;

[0029] ② Mix 2 g of cyclodextrin with 98 g of water, heat up to 80°C at a stirring speed of 5000 rpm, and prepare a cyclodextrin solution with a concentration of 2% by mass;

[0030] ③Reduce the temperature of the cyclodextrin solution to 58°C, and slowly add the potato starch emulsion to the cyclodextrin solution at a stirring speed of 5000 rpm. After adding the potato starch emulsion, raise the temperature to 68°C, and stir at a constant temperature for 10 Minutes, stand still, cool naturally, discard the supernatant, wash and dry to prepare the potato starch microspheres.

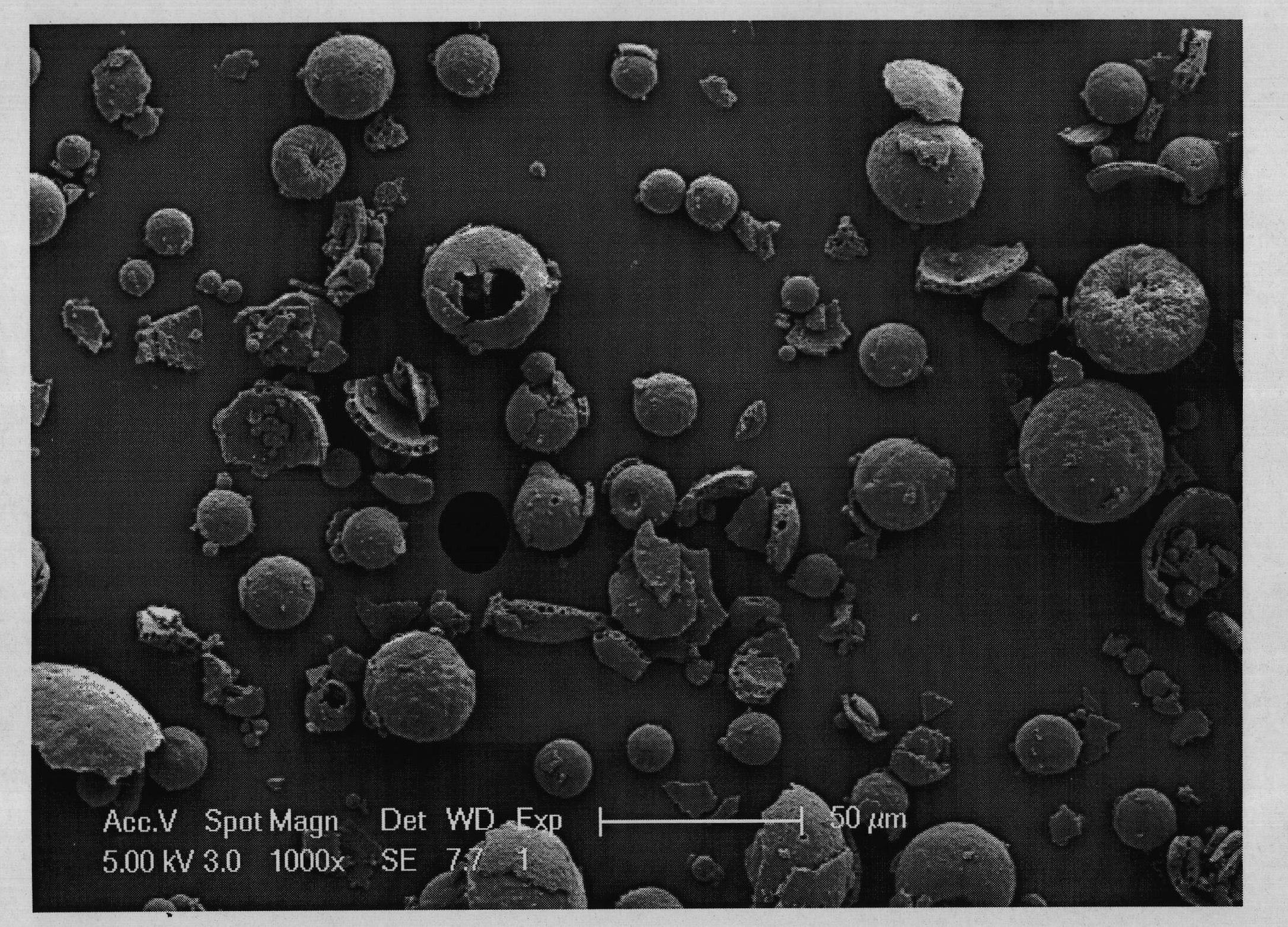

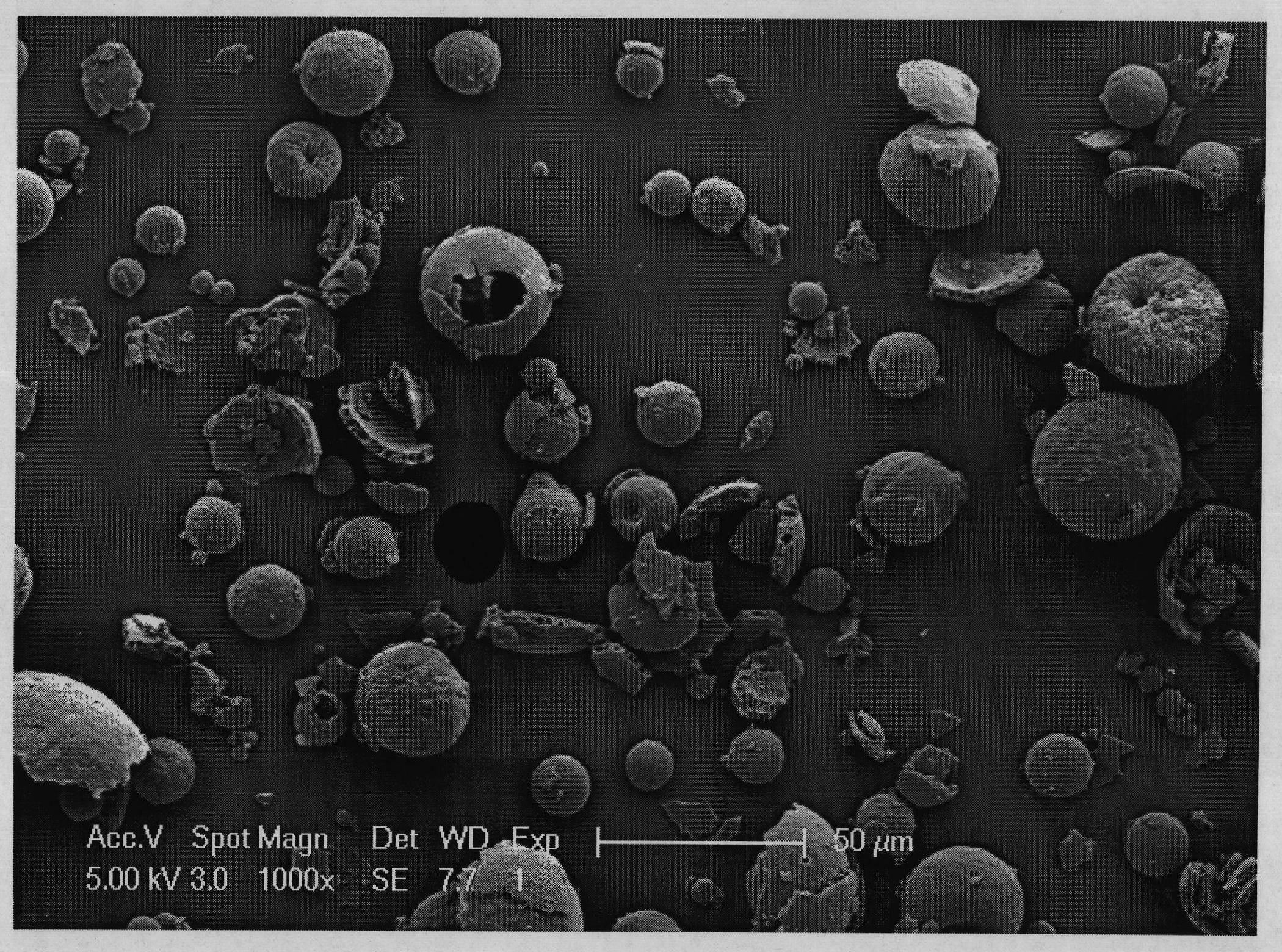

[0031] In order to see the internal structure of the prepared starch microspheres more intuitively, the starch microsphere sample was partially ground during the preparation of the sample under the scanning electron m...

Embodiment 2

[0033] Preparation of tapioca starch microspheres:

[0034] 1. 30g tapioca starch is mixed with 120g water, and the preparation mass percentage concentration is the tapioca starch emulsion of 20%;

[0035] ② Mix 7.5g of polyvinylpyrrolidone with 42.5g of water, heat up to 40°C at a stirring speed of 1000 rpm, and prepare a polyvinylpyrrolidone solution with a concentration of 15% by mass;

[0036] ③Raise the temperature of the polyvinylpyrrolidone solution to 50°C, slowly add the tapioca starch emulsion to the polyvinylpyrrolidone solution at a stirring speed of 1000 rpm, after adding the tapioca starch emulsion, raise the temperature to 65°C, and stir at a constant temperature After 10 minutes, stand still, cool naturally, discard the supernatant, wash and dry to prepare tapioca starch microspheres with a particle size of 70-100 μm and a wall thickness of 7-10 μm.

Embodiment 3

[0038] Preparation of yam starch microspheres:

[0039] 1. Mix 10g of yam starch with 10g of water to prepare a 50% yam starch emulsion;

[0040] 2. Mix 5g of xanthan gum with 45g of water, heat up to 45°C at a stirring speed of 3000 rpm, and prepare a xanthan gum solution with a concentration of 10% by mass;

[0041] ③Raise the temperature of the xanthan gum solution to 60°C, slowly add the yam starch emulsion to the xanthan gum solution at a stirring speed of 2000 rpm, after adding the yam starch emulsion, raise the temperature to 70°C, and stir at a constant temperature Stand for 30 minutes, cool naturally, discard the supernatant, wash, and dry to prepare yam starch microspheres with a particle size of 20-50 μm and a wall thickness of 1-2 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com