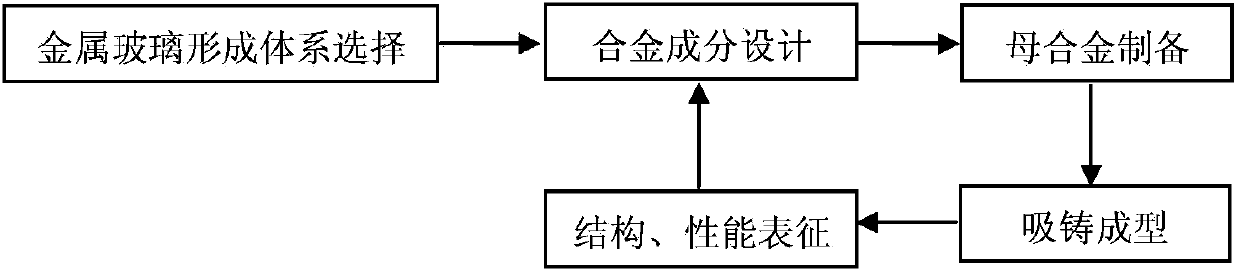

Zirconium-based metallic glass multi-phase composite material and preparation method thereof

A technology of zirconium-based metallic glass and composite material, which is applied in the field of zirconium-based metallic glass multiphase composite material and its preparation, can solve the problems such as the decrease of the strength of the composite material, and achieve the effect of improving the strength and the forming ability of strong glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

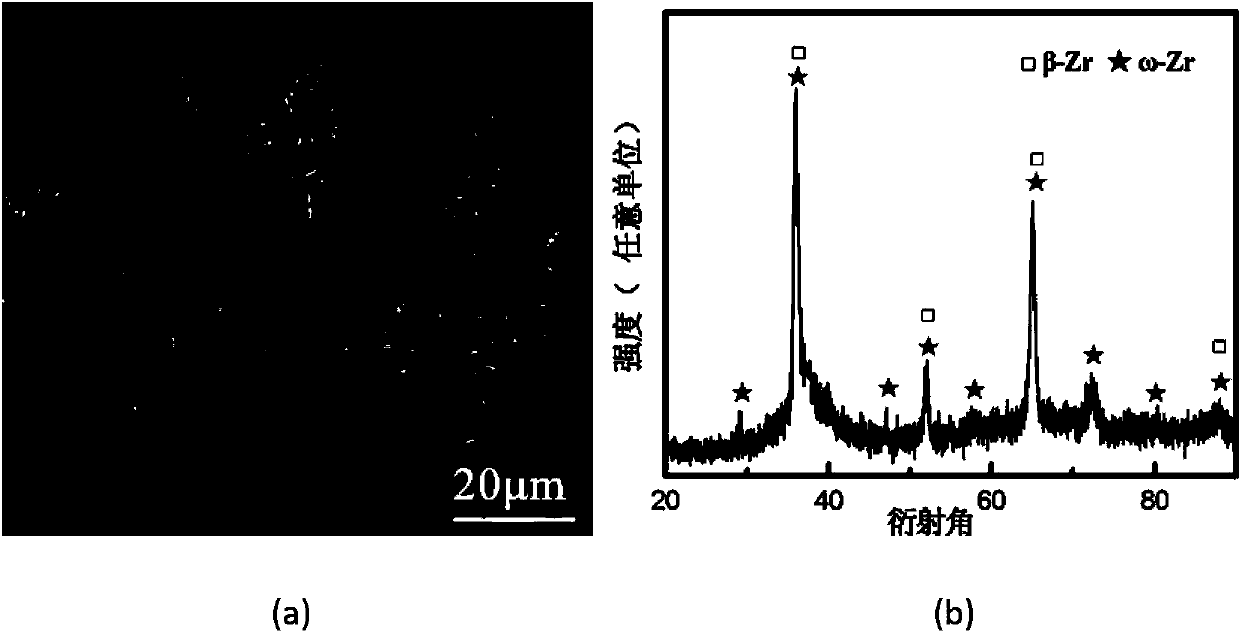

Embodiment 1

[0028] (1) Selection of raw materials

[0029] The purity of each metal component that the present invention prepares master alloy ingot for selection is as table 1, and alloy composition is Zr 60 Ti 20 Cu 5.6 Ni 4.4 be 10 (atomic percent).

[0030] Table 1 The purity (%) of metal components selected for the preparation of master alloy ingots

[0031] alloy element Zr Ti Cu Ni be purity / % 99.95 99.95 99.99 99.99 99.5

[0032] (2) Preparation of master alloy ingot

[0033] Under the conditions of Ti inhalation and high-purity argon protection, master alloy buckle ingots are melted in a non-consumable arc melting furnace. The specific procedures are as follows:

[0034] a. After mechanically grinding the surface of the metal raw material to remove the oxide skin on the surface, prepare the material according to the designed composition ratio; put the prepared material into the water-cooled copper crucible in the melting furnace according ...

Embodiment 2

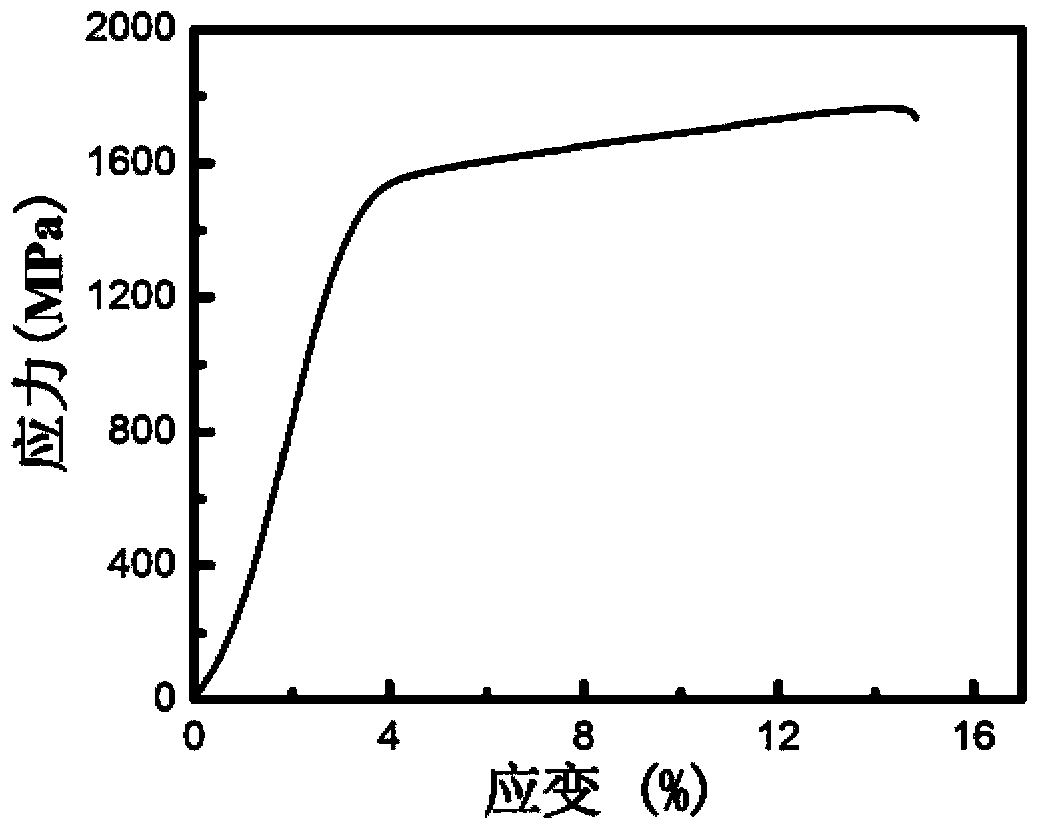

[0044] Adopt the method identical with embodiment 1, alloy composition is Zr 56.3 Ti 18.7 Cu 6.9Ni 5.6 be 12.5 , prepared a 25mm diameter zirconium-based metallic glass multiphase composite material, the yield strength reached 1580MPa, and the compression plasticity reached 8%.

Embodiment 3

[0046] Adopt the method identical with embodiment 1, alloy composition is Zr 52 Ti 17 Cu 9 Ni 7 be 15 , prepared a 30mm diameter zirconium-based metallic glass multiphase composite material, the yield strength exceeded 1650MPa, and the compression plasticity reached 6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com