Short glass fiber reinforced polypropylene composite material and preparation method thereof

A technology of composite materials and polypropylene, which is applied in the field of short glass fiber reinforced polypropylene composite materials and its preparation, can solve the problems of low impact strength, poor fluidity, and low floating fibers of materials, so as to improve toughness and impact resistance, improve Effect of grafting rate and improvement of dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

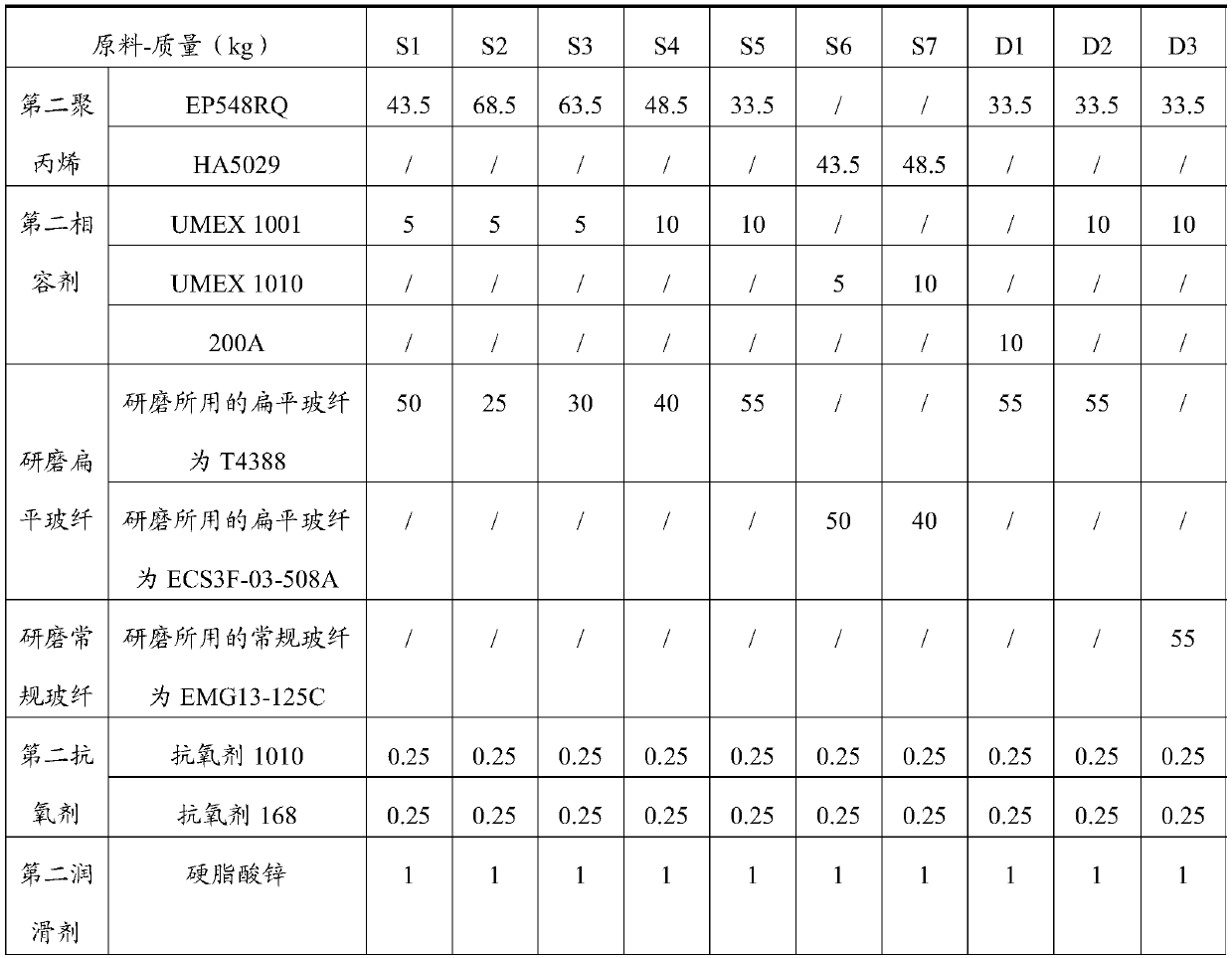

[0069] Embodiment 1-7 (being S1-7) and comparative example 1-3 (being D1-3)

[0070] According to each raw material and consumption thereof in table 1, carry out the preparation of grinding flat glass fiber master batch and grinding conventional glass fiber master batch;

[0071] The preparation method is as follows: according to Table 1, each raw material is weighed and added to an internal mixer for internal mixing and grafting; then it is extruded and granulated by a single screw to obtain ground glass fiber masterbatches A1-7 and A1'-3'( Including grinding flat glass fiber masterbatch and grinding regular glass fiber masterbatch);

[0072] The preparation conditions are shown in Table 2, and the prepared ground flat masterbatch is shown in Table 3.

[0073] Raw materials and their dosage in Table 1 S1-7 and D1-3

[0074]

[0075] Preparation conditions in Table 2 S1-7 and D1-3

[0076] Preparation conditions S1 S2 S3 S4 S5 S6 S7 D1 D2 D3 Mixin...

Embodiment 8-14

[0079] Embodiment 8-14 (being S8-14) and comparative example 4-6 (being D4-6)

[0080] According to each raw material and consumption thereof in table 4, carry out the preparation of short glass fiber reinforced polypropylene composite material;

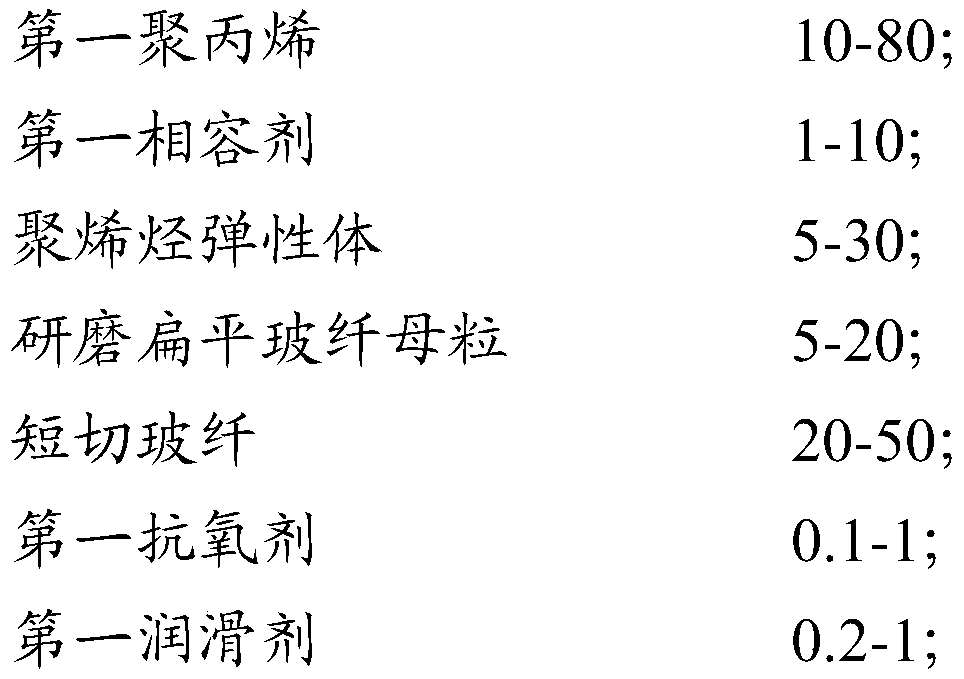

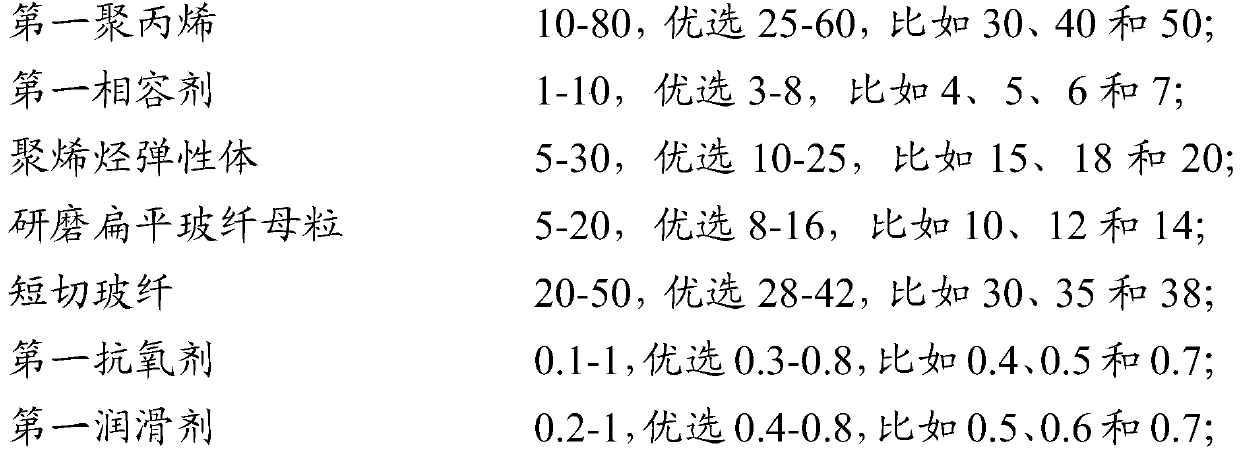

[0081]The preparation method is as follows: take each raw material according to Table 4, grind the glass fiber masterbatches A1-7 and A1'-3' (ground flat glass fiber masterbatches or Grinding conventional glass fiber masterbatch) and the first polypropylene, the first compatibilizer, polyolefin elastomer, the first antioxidant and the first lubricant are mixed together and then sent into the twin-screw extruder through the main feed port, Feed the chopped glass fiber into the twin-screw extruder through the side feeding port, and then extrude and granulate to obtain short glass fiber reinforced polypropylene composite materials B1-7 and B1'-3';

[0082] Wherein, the preparation conditions are as follows: the aspect ratio of the twin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com