Oxidized zinc ore flotation reagent and method

A flotation agent and oxidation type technology, applied in flotation, solid separation and other directions, can solve the problems of low grade of zinc concentrate, high production cost, and difficulty in recycling and utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

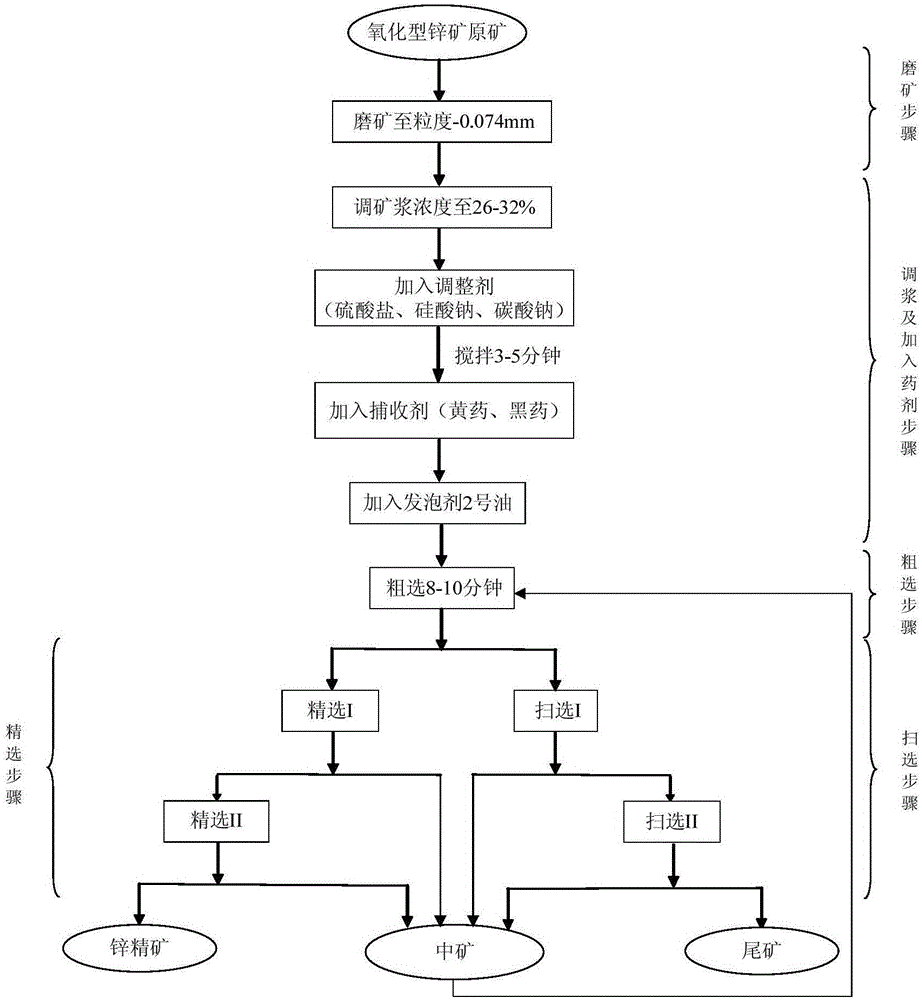

[0047] Select 1000g of an oxidized zinc-lead ore in Liaoning, first grind the zinc-lead ore to a particle size of -0.074mm (ie below 200 mesh) and account for 90% of the original ore content; then adjust the slurry concentration of the ground zinc-lead ore to 30.3%, and then add regulators in sequence: sodium carbonate 60g / t, sodium silicate 200g / t, sulfate (Na 2 SO 4 、CuSO 4 etc.) 350g / t, after stirring for 3 minutes, add collectors sequentially: xanthate 130g / t, black medicine 700g / t, foaming agent: No. 2 oil 120g / t; figure 1 The first roughing, second beneficiation, and second sweeping steps described in the above-mentioned flotation method shown in , and the middle ore in the process is returned to the roughing for recirculation, that is, roughing, beneficiation and sweeping, and again To obtain zinc concentrate, gradually increase the grade of zinc concentrate and the recovery rate of zinc, the grade of zinc concentrate can be obtained to be 58.76%, and the recovery rat...

Embodiment 2

[0049] Select 1000g of an oxidized zinc-lead ore in Jilin, first grind the zinc-lead ore to a particle size of -0.074mm (that is, below 200 mesh) and account for 90% of the raw ore content; then adjust the slurry concentration of the ground zinc-lead ore to 29%, and then add the adjuster in turn: sulfate (Na 2 SO 4 、CuSO 4 etc.) 180g / t, sodium silicate 200g / t, sodium carbonate 50g / t, after stirring for 4 minutes, add collectors in sequence: xanthate 160g / t, black medicine 60g / t, foaming agent: No. 2 oil 130g / t t; figure 1 The first roughing, second beneficiation, and second sweeping steps described in the above-mentioned flotation method shown in , and the middle ore in the process is returned to the roughing for recirculation, that is, roughing, beneficiation and sweeping, and again To obtain zinc concentrate, gradually increase the grade of zinc concentrate and the recovery rate of zinc, the grade of zinc concentrate can be obtained to be 52.68%, and the recovery rate of ...

Embodiment 3

[0051] Select 1000g of an oxidized zinc-lead ore in Liaoning, first grind the zinc-lead ore to a particle size of -0.0074mm (that is, below 200 mesh) and account for 92% of the original ore content; then adjust the slurry concentration of the ground zinc-lead ore to 30%, and then add regulators in sequence: sodium carbonate 100g / t, sodium silicate 360g / t, sulfate (Na 2 SO 4 、CuSO 4 etc.) 400g / t, after stirring for 4.5 minutes, sequentially add collectors: xanthate 200g / t, black medicine 160g / t, foaming agent: No. 2 oil 125g / t; figure 1 The first roughing, second beneficiation, and second sweeping steps described in the above-mentioned flotation method shown in , and the middle ore in the process is returned to the roughing for recirculation, that is, roughing, beneficiation and sweeping, and again To obtain zinc concentrate, gradually increase the grade of zinc concentrate and the recovery rate of zinc, the grade of zinc concentrate can be obtained to be 55.6%, and the recov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com