Flame-retardant polyamide fiber and preparation method thereof

A flame-retardant polyester and fiber technology, applied in the field of flame-retardant fibers, can solve the problems of high cost, inability to balance mechanical properties and flame-retardant properties, and achieve the effects of reducing dosage, improving spinnability and mechanical properties, and expanding surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of flame-retardant polyester fiber, its preparation process is:

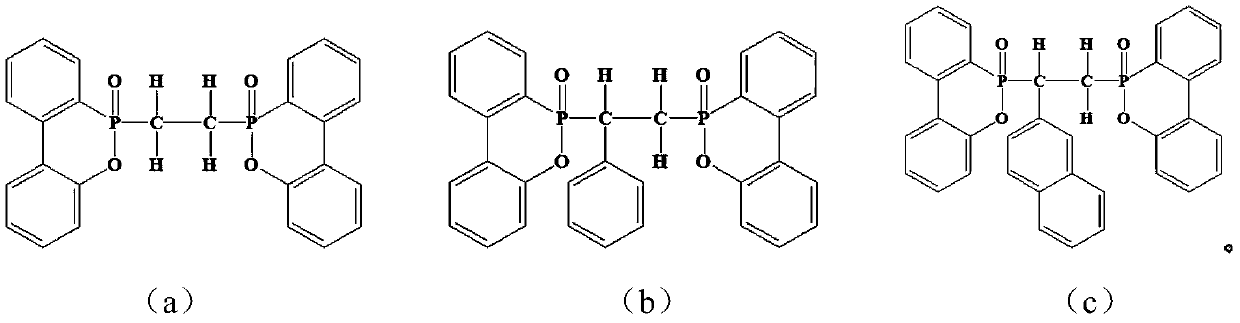

[0031] (1) In terms of parts by mass, 93 parts of polyethylene terephthalate, 1.4 parts of melamine cyanurate, 0.3 parts of graphite-like carbon nitride, 0.3 parts of zinc sulfide and 5 parts of 9,10-bis Hydrogen-9-oxa-10-phosphaphenanthrene-10-oxide derivatives were melt blended to prepare flame-retardant polyester chips, in which, 9,10-dihydro-9-oxa-10-phosphaphenanthrene- The structural formula of the 10-oxide derivative is:

[0032]

[0033] (2) Dry and pre-crystallize the flame-retardant polyester chips. The process is as follows: firstly, the temperature is raised from 25 °C to 100 °C at a rate of 5 °C / min, and the temperature is kept for 10 hours. Cool to 25°C;

[0034] (3) Melt spinning and drawing and winding are carried out to obtain flame-retardant polyester fibers. The temperature of melt blending is 275°C, the temperature of melt spinning is 280°C, and the speed of drawing and win...

Embodiment 2

[0037] A kind of flame-retardant polyester fiber, its preparation process is:

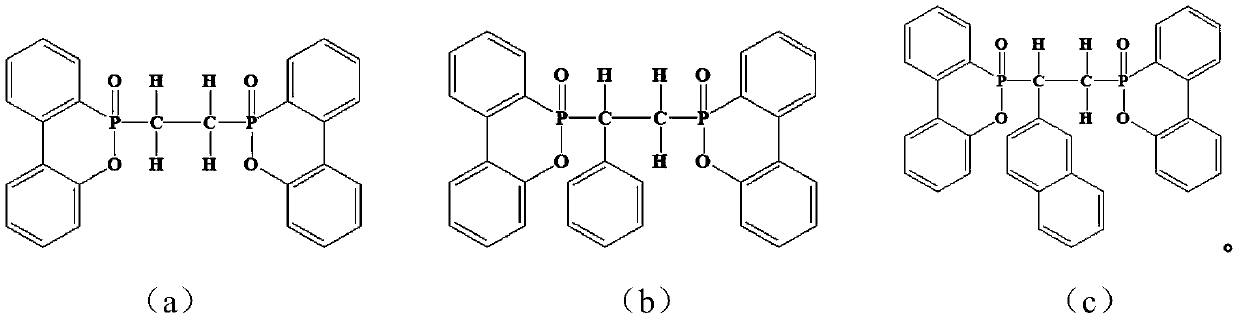

[0038] (1) In parts by mass, 92 parts of polyethylene terephthalate, 2 parts of melamine cyanurate, 0.5 part of graphite-like carbon nitride, 0.5 part of zinc diethylphosphinate and 5 parts of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide derivatives were melt-blended to prepare flame-retardant polyester chips, wherein, 9,10-dihydro-9-oxa-10 - The structural formula of phosphaphenanthrene-10-oxide derivatives is:

[0039]

[0040] (2) Dry and pre-crystallize the flame-retardant polyester chips. The process is as follows: firstly, the temperature is raised from 20 °C to 109 °C at a rate of 7 °C / min, and the temperature is kept for 10 hours. Cool to 20°C;

[0041] (3) Melt spinning and drawing and winding are carried out to obtain flame-retardant polyester fibers. The temperature of melt blending is 260°C, the temperature of melt spinning is 270°C, and the speed of drawing and winding is 30...

Embodiment 3

[0044] A kind of flame-retardant polyester fiber, its preparation process is:

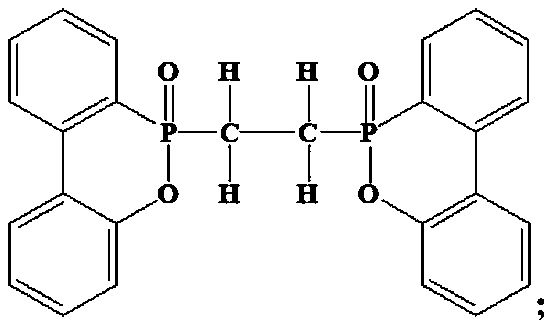

[0045](1) In parts by mass, 95 parts of polytrimethylene terephthalate, 1 part of melamine cyanurate, 0.5 part of graphite-like carbon nitride, 0.5 part of 2-carboxyethylphenyl phosphinate zinc and 3 parts of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide derivatives were melt-blended to prepare flame-retardant polyester chips, wherein 9,10-dihydro-9-oxa The structural formula of -10-phosphaphenanthrene-10-oxide derivatives is:

[0046]

[0047] (2) Dry and pre-crystallize the flame-retardant polyester chips. The process is as follows: firstly, the heating rate is raised from 15°C to 115°C at a rate of 9°C / min, and the temperature is kept for 10 hours. Cool to 15°C;

[0048] (3) The flame retardant polyester fiber is obtained by melt spinning and drawing and winding, the temperature of melt blending is 270°C, the temperature of melt spinning is 280°C, the speed of drawing and winding is 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com