Patents

Literature

37results about How to "Synergistic flame retardant effect is good" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

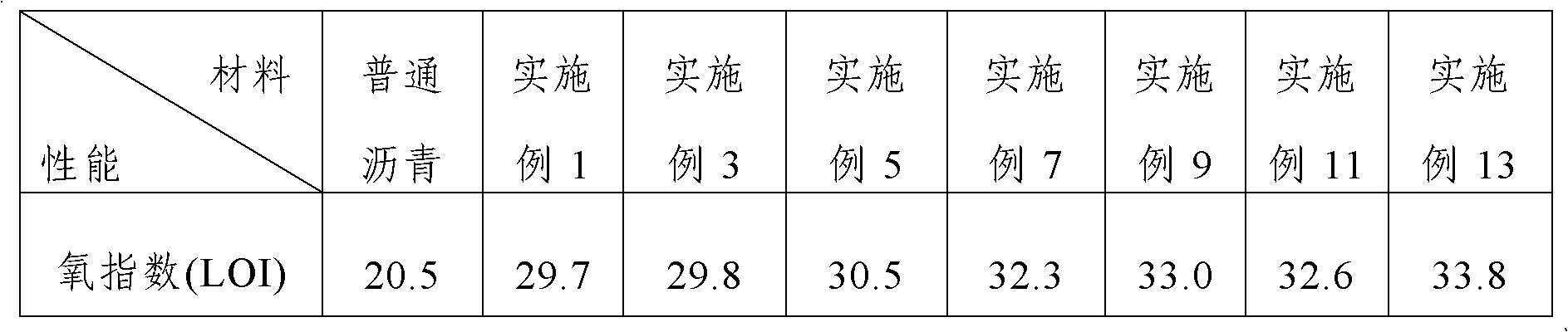

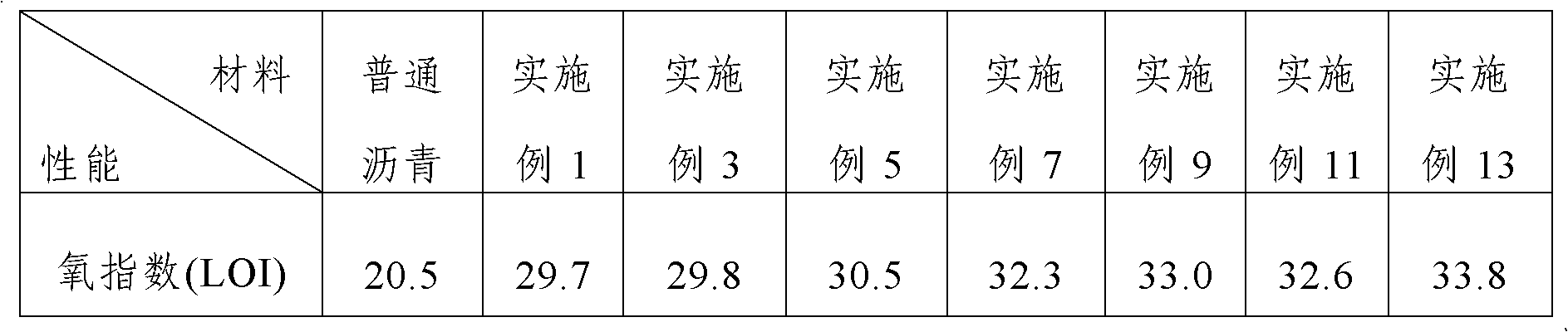

Synergic flame retardance asphalt material and preparation method thereof

InactiveCN102604396AImprove flame retardant performanceImprove application performanceBuilding insulationsMagnesiumBituminous materials

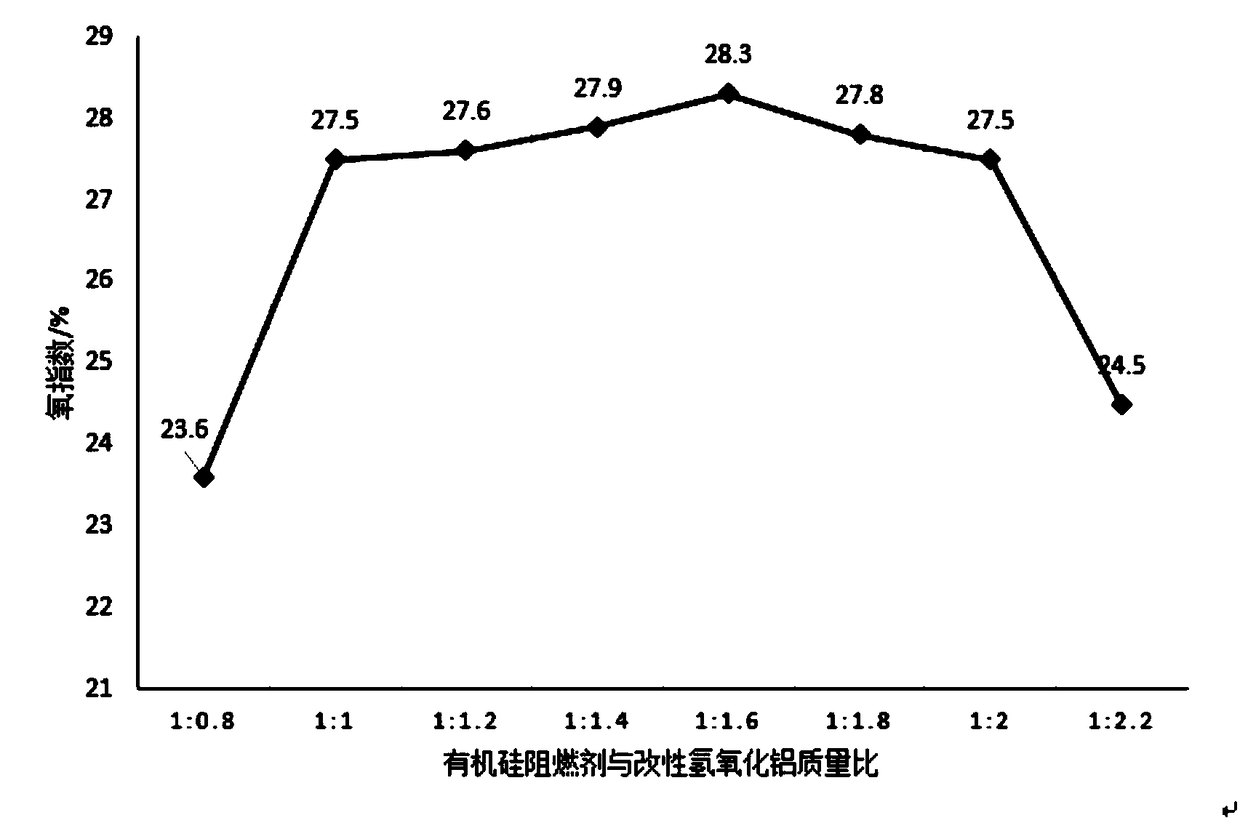

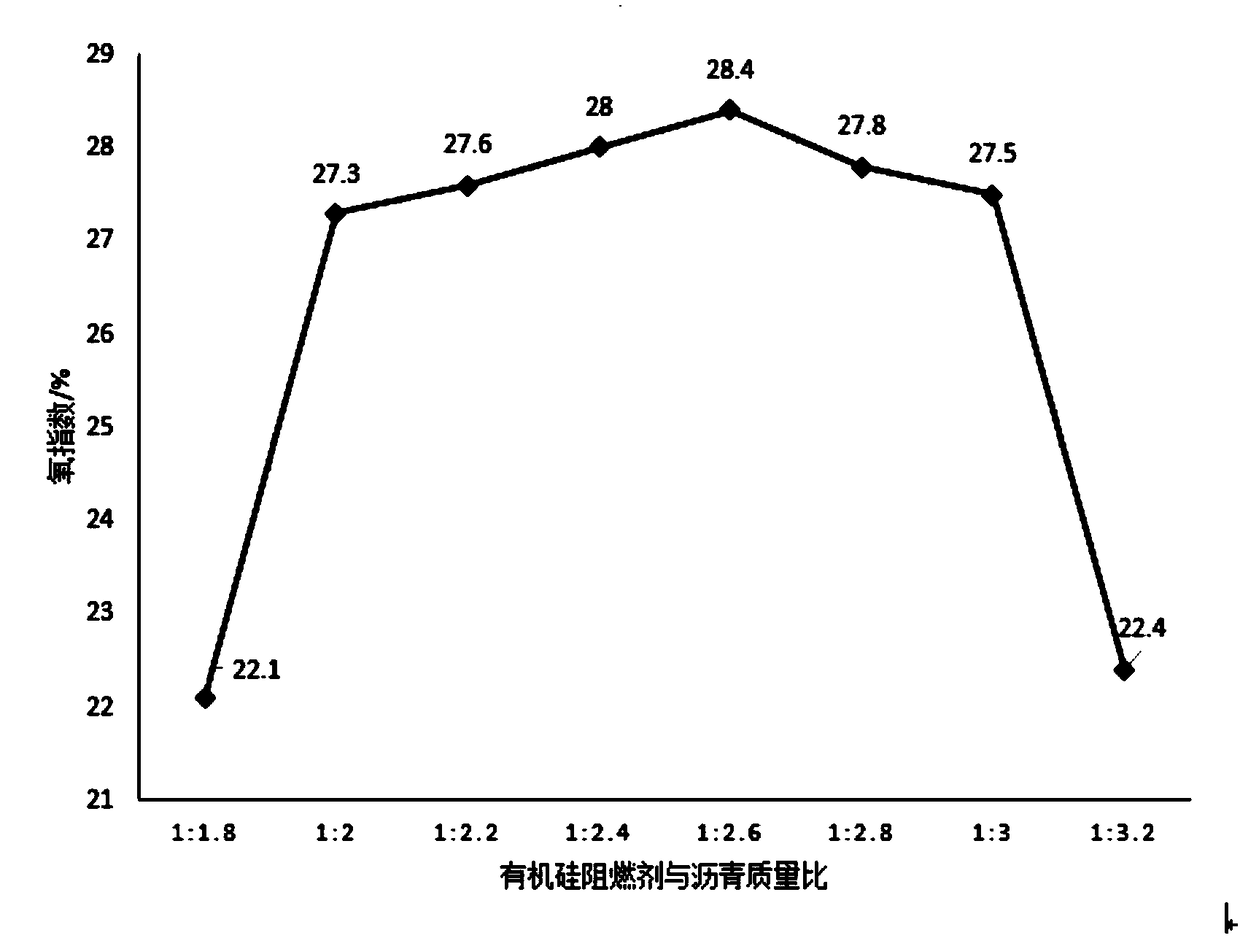

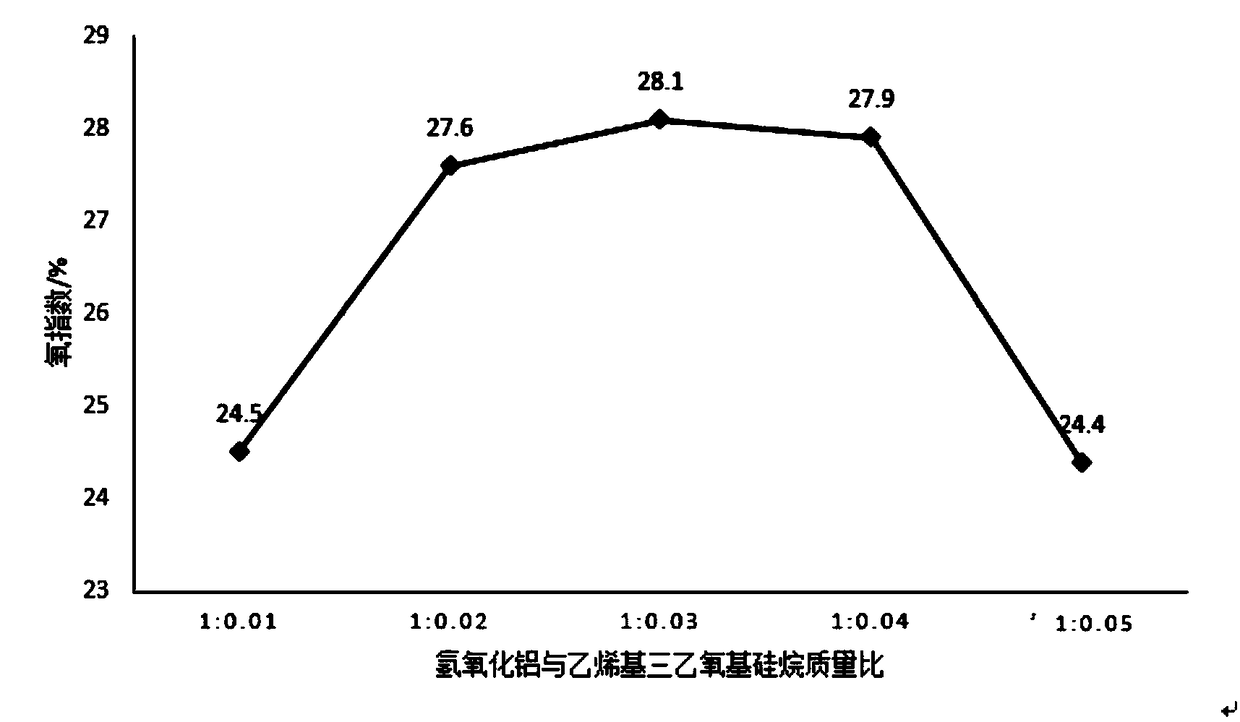

The invention discloses a synergic flame retardance asphalt material, which is characterized in that the asphalt material is prepared by mixing the following raw materials in parts by weight: 100 of asphalt, 0.2-40 of metal hydroxide, 0.1-30 of layered silicate; the asphalt is one or more of petroleum asphalt, rock asphalt and coal pitch; and the metal hydroxide is aluminum hydroxide and / or magnesium hydroxide. The invention also provided a preparation method of the synergic flame retardance asphalt material. According to the invention, the synergic flame retardance function of the metal hydroxide and the layered silicate is utilized to perform nano composite modification on asphalt; compared with the common organic flame retardant (such as a halogen flame retardant), the flame retardance technique adopted by the synergic flame retardance asphalt material is a green, non-toxic and environmentally friendly flame retardance technique; and the various road performances of the flame retardance asphalt material are good, the use requirements are met, the period of the storage stability can reach above one year, and the temperature sensitivity and the ageing resistance are obviously better than those of common asphalt.

Owner:CHANGAN UNIV

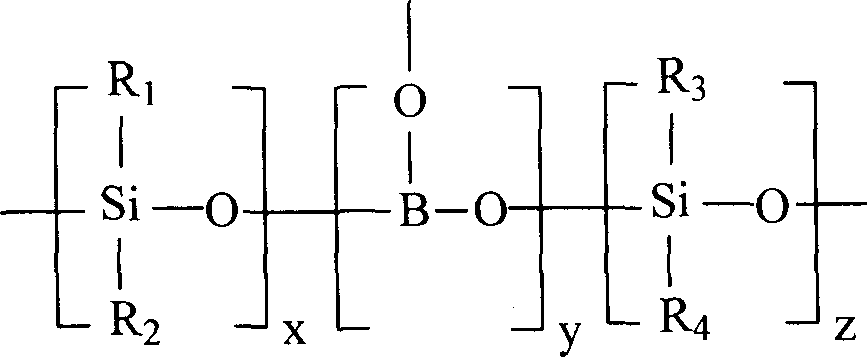

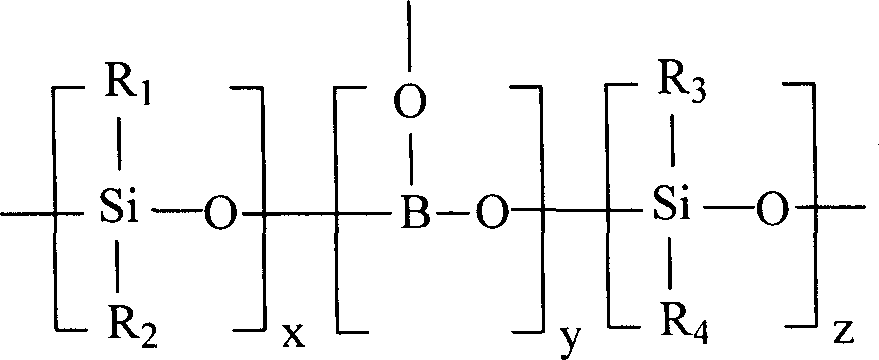

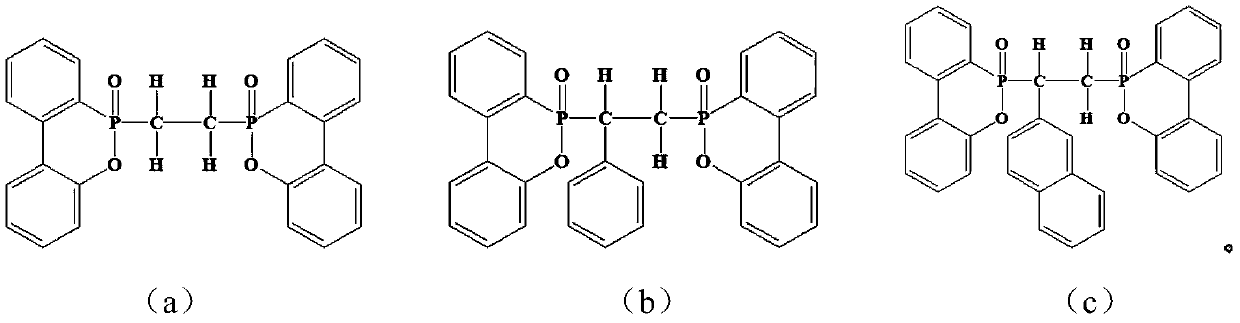

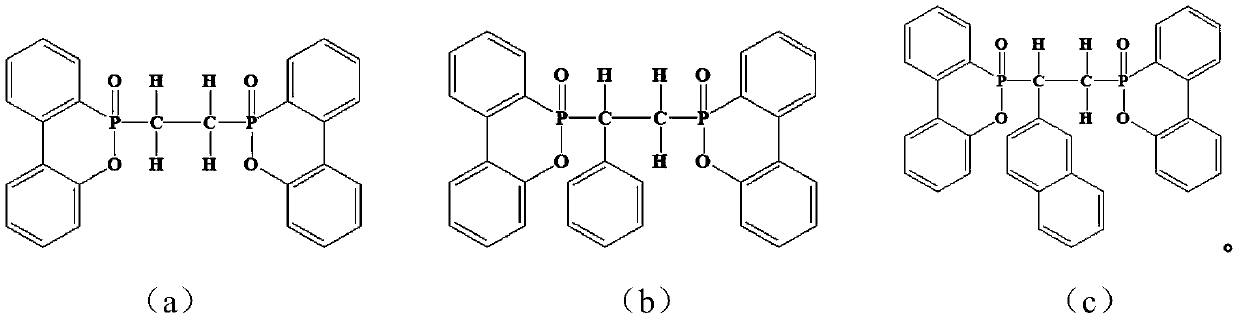

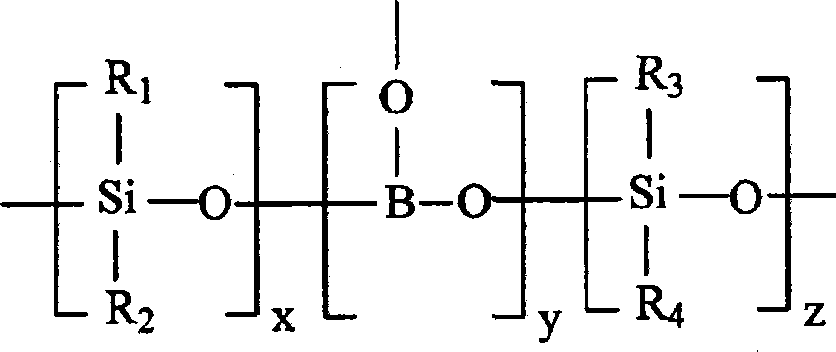

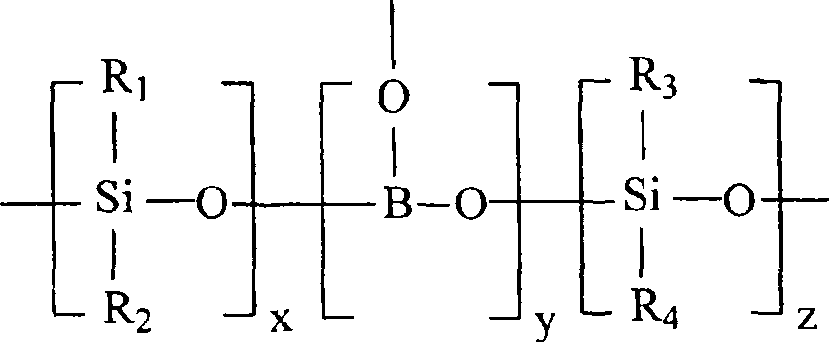

Silicious fire retard ant for polyolefin and its prepn and application

The present invention provides one kind of silicious fire retardant for polyolefin with the molecular structure as shown. The fire retardant is white or yellowish powder and has smelting temperature of 220-260 deg.c. The present invention provides the preparation process of the silicious fire retardant and the application of the silicious fire retardant as halogen-free environment fire retarding additive for polyolefin material.

Owner:SOUTH CHINA UNIV OF TECH

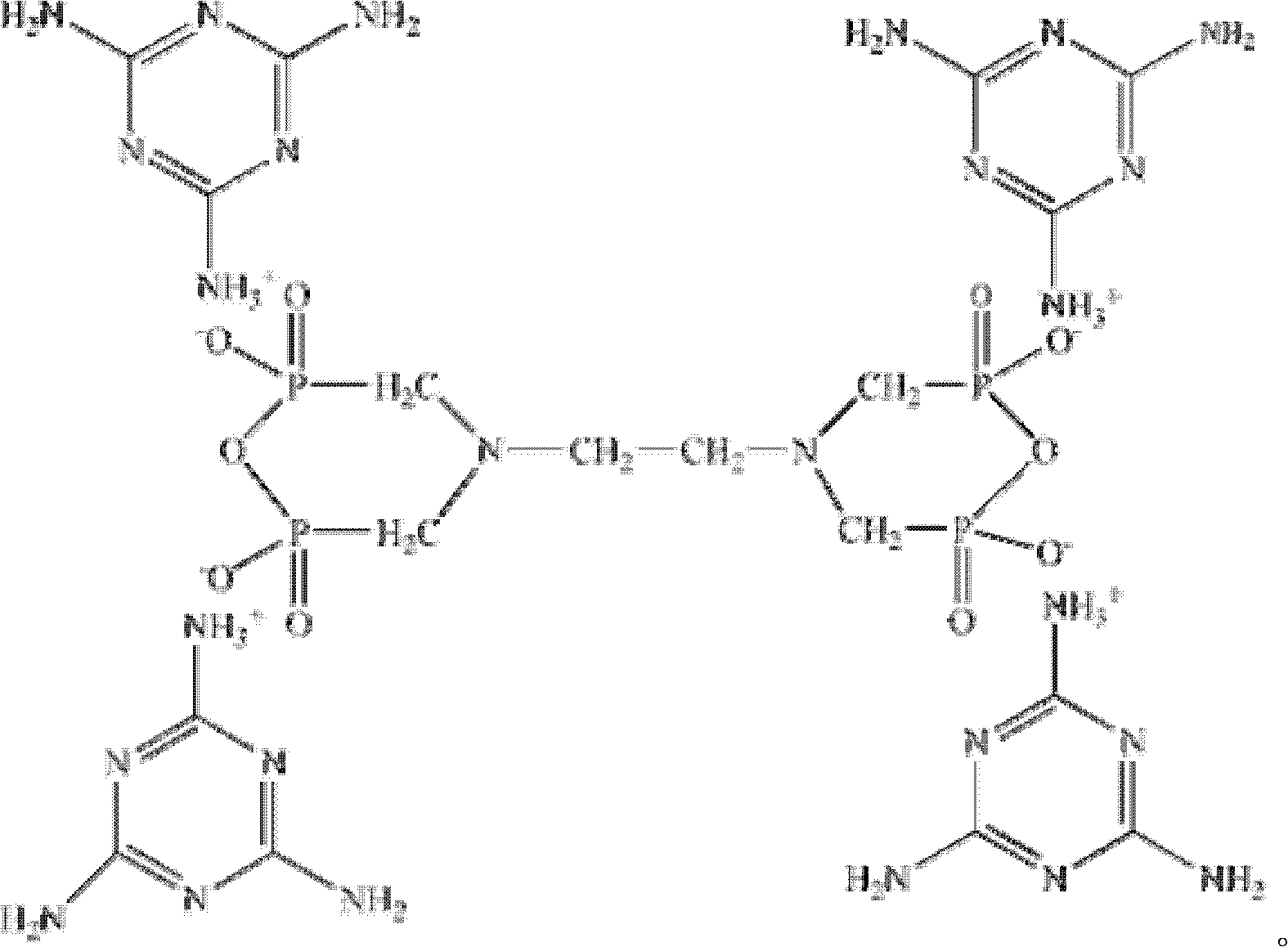

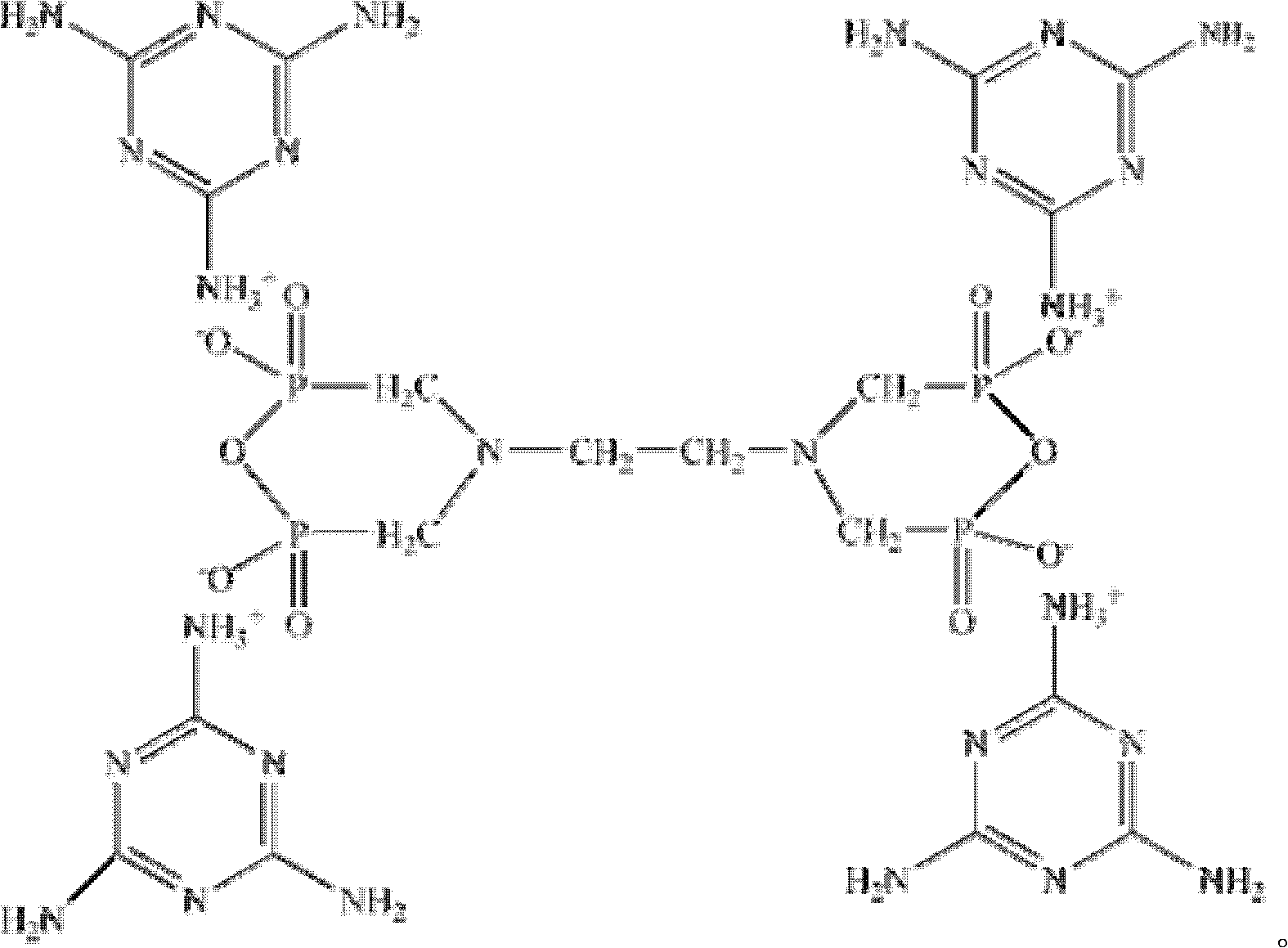

Ethylenediamine bicyclo-tetra methylenemelamine phosphonate compound and preparation method thereof

InactiveCN102675372AReaction is easy to controlNo pollution in the processGroup 5/15 element organic compoundsPolyesterEthylenediamine

The invention relates to an ethylenediamine bicyclo-tetra methylene melamine phosphonate compound and a preparation method thereof, in particular to a novel ethylenediamine bicyclo-tetra methylene melamine phosphonate for polymer flame retardance and the preparation method thereof. The compound synthesized by a two-step method has the characteristics of high phosphor / nitrogen content, high thermal stability, good hydrolysis resistance and the like, wherein due to triazine ring and phosphor-oxygen-nitrogen six-membered heterocyclic ring in the molecular structure, the thermal stability of the compound is greatly improved, the decomposition temperature of the compound is higher than 280 DEG C; and the charing property and flame retardance of a flame retarding system can be greatly improved due to the triazine ring structure in the molecular structure, and the excellent synergetic flame retarding effect of organic phosphor and six-membered heterocyclic ring can be represented. The compound synthesized by the invention can be widely applied to flame retardance of various synthetic materials and textiles such as polyolefin, polyurethane, nylon and polyester; raw materials for synthesizing the compound are easy to obtain, the production process is simple, and is suitable for industrial production and application.

Owner:DONGHUA UNIV

Environment-friendly fireproof material for electrical equipment and preparation method thereof

ActiveCN106497339AReduce solubilityImprove thermal stabilityFireproof paintsEpoxy resin coatingsFiberCrack resistance

The invention provides an environment-friendly fireproof material for electrical equipment and a preparation method of the environment-friendly fireproof material, and belongs to the fields of fireproof materials and preparation technologies thereof. The environment-friendly fireproof material for the electrical equipment is characterized by being prepared from the following raw materials in parts by weight: 50 to 60 parts of modified epoxy resin, 30 to 40 parts of fluorocarbon resin, 60 to 90 parts of a fire retardant, 3 to 10 parts of expanded graphite, 3 to 10 parts of alumina silicate fiber and 2 to 8 parts of molecular sieves. The fireproof material provided by the invention is applied to fire protection of the electrical equipment, and is high in crack resistance, water resistance and weather resistance and good in expansion character; meanwhile, the heat release rate of a base material in a burning condition can be obviously reduced, and the quality loss is reduced; moreover, the fireproof material is small in smoke production quantity and good in environmental protection effect.

Owner:STATE GRID HENAN ELECTRIC ZHOUKOU POWER SUPPLY

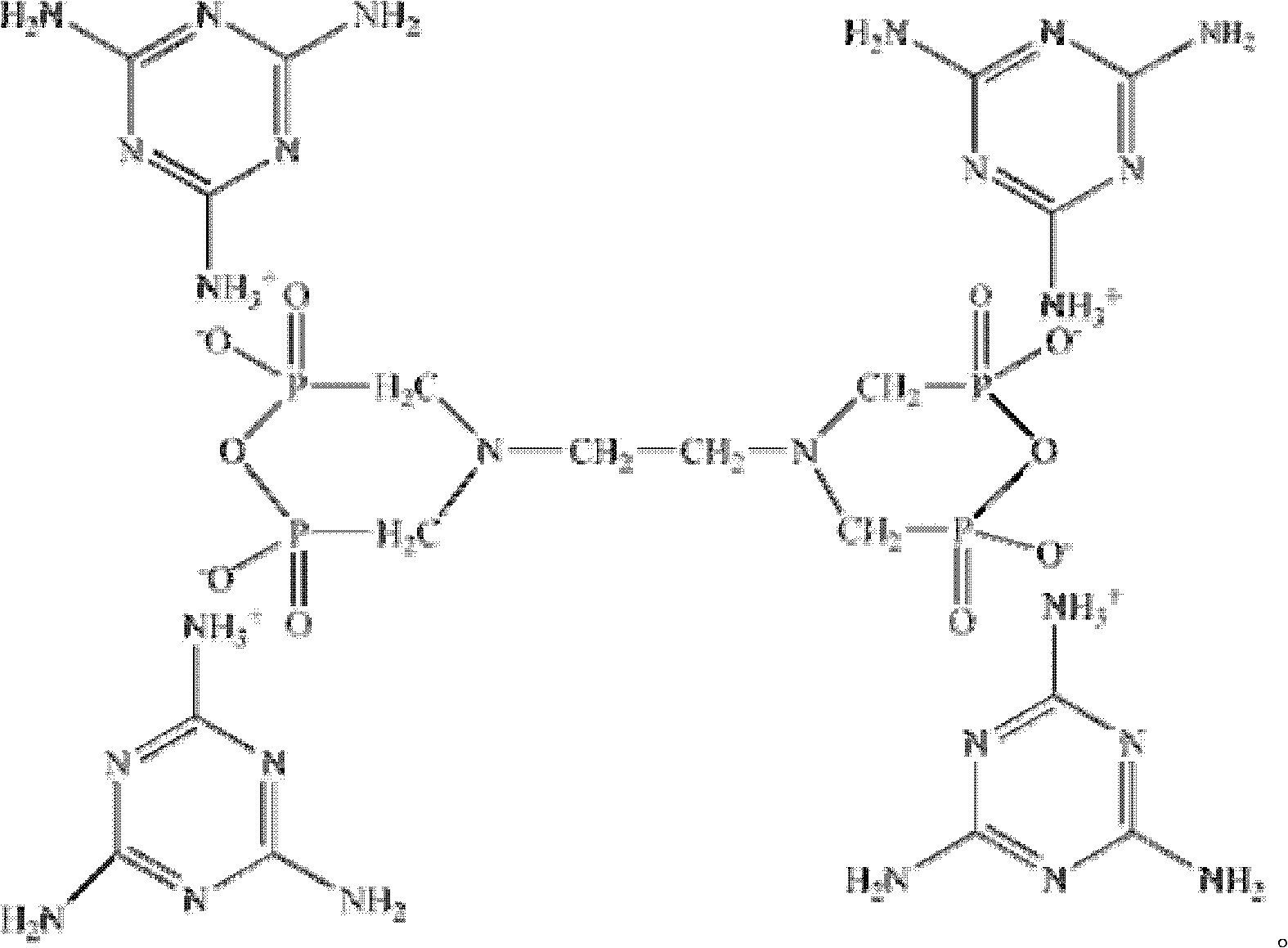

Grade-1E K2-type radiation cross-linked halogen-free flame-retardant cable material for nuclear power plant and preparation method thereof

ActiveCN103087395AEnvironmental protection is goodReduce pollutionPlastic/resin/waxes insulatorsInsulated cablesCross-linkProcedure Agents

The invention relates to a grade-1E K2-type radiation cross-linked halogen-free flame-retardant cable material for a nuclear power plant and a preparation method thereof, belonging to the field of new chemical materials. The cable material comprises raw materials including base resin EVA (ethylene-vinyl acetate copolymer), flame retardants A and B, a flame retardant synergist, basic antioxidants 1010 and 168, a radiation-resistant auxiliary agent 4,4'-thiobis(6-tertiary-butyl-3-methylphenol) and a processing agent; and the preparation method comprises the process steps of material weighing, pretreatment, mixing, extrusion granulation, drying and the like. The cable material is a red-phosphorus-free halogen-free environment-friendly flame-retardant material, phenoxy polyphosphazene is used as a main flame retardant in a flame-retardant system of the cable material, an inorganic flame retardant is auxiliary, the flame-retardant system accounts for a small weight percentage of the material, and the cable material is high in flame-retardant efficiency and excellent in mechanical properties, processability and radiation resistance, so that the cable material is a novel environment-friendly flame-retardant material which has excellent comprehensive properties and is suitable for a nuclear power plant environment.

Owner:SICHUAN INST OF ATOMIC ENERGY +1

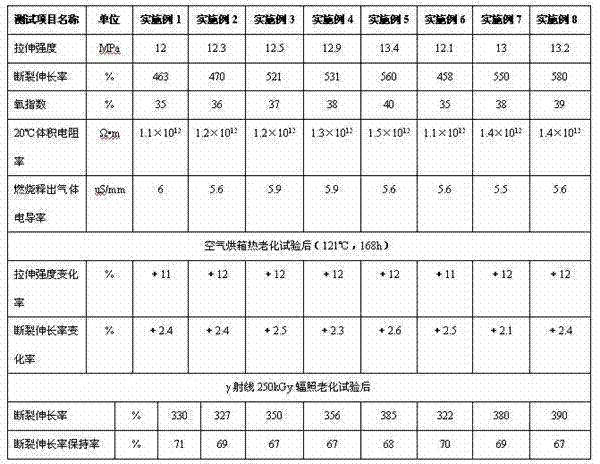

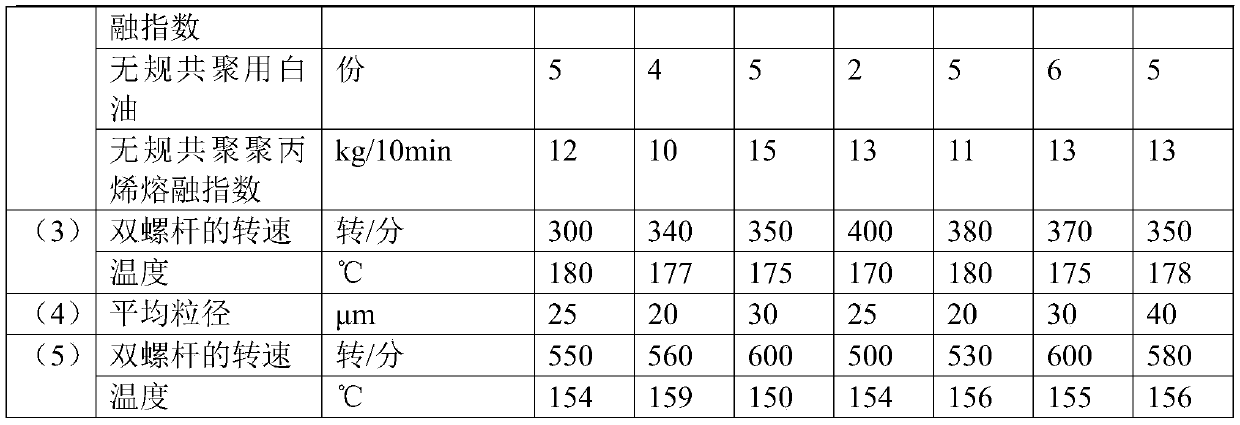

Polypropylene carrier high-efficiency halogen-free flame-retardant master batch and preparation method thereof

The invention relates to a polypropylene carrier high-efficiency halogen-free flame-retardant master batch and a preparation method thereof. The preparation method comprises the steps: a polypropylenematrix and an additive are subjected to melt blending to prepare a polypropylene carrier high-efficiency halogen-free flame-retardant master batch; the additive comprises a flame-retardant filler, the polypropylene matrix is polypropylene random copolymer, and the flame-retardant filler is a flame-retardant filler subjected to double-coating, wherein the double-coating process comprises the steps: treating the flame-retardant filler with a coupling agent is treated, and the treated flame-retardant filler and homo-polypropylene are subjected to melt extrusion granulation and then ground. The finally prepared polypropylene carrier high-efficiency halogen-free flame-retardant master batch is mainly composed of the polypropylene random copolymer and the double-coated flame-retardant filler dispersed in the polypropylene random copolymer; the polypropylene carrier high-efficiency halogen-free flame-retardant master batch has excellent flame retardancy, and the material modified by the polypropylene carrier high-efficiency halogen-free flame-retardant master batch has excellent mechanical properties. The method is simple and feasible; the flame-retardant master batch prepared by the method is excellent in flame-retardant effect, does not cause reduction of mechanical properties of the modified material, and completely meets environmental protection requirements due to a halogen-freeflame-retardant system.

Owner:珠海鑫科高分子材料有限公司

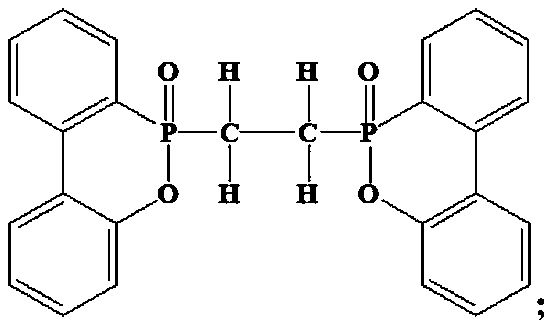

High-flame-retardant waterborne polyurethane and preparation method thereof

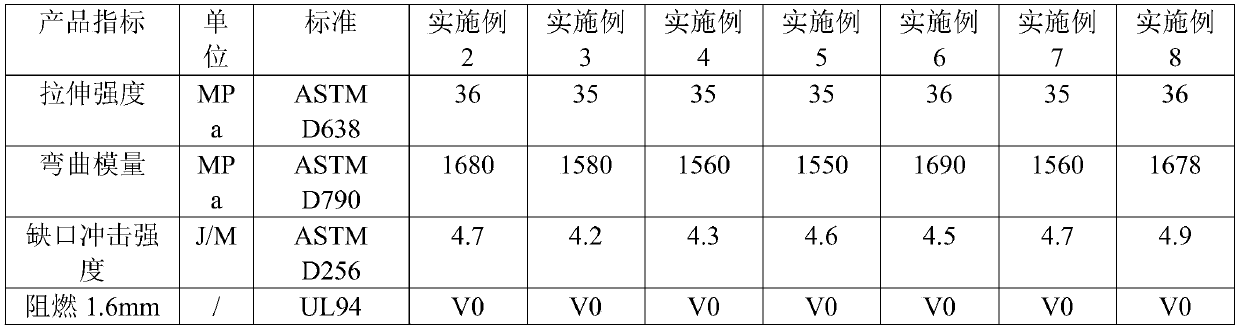

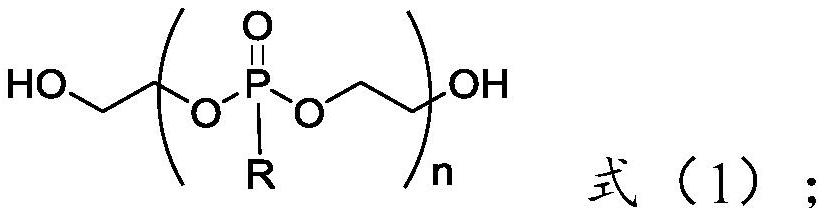

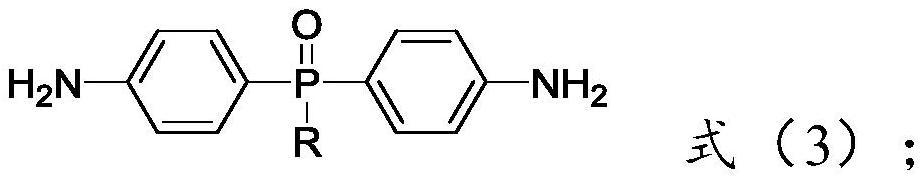

The invention provides waterborne polyurethane and a preparation method thereof. The preparation method comprises the following steps: letting phosphorus-free polyol react with specific phosphorus-containing polyol as shown in a formula (1), a phosphorus-containing stabilizer as shown in a formula (2) and polyisocyanate to form a prepolymer, emulsifying, and reacting with a phosphorus-containing chain extender to form the waterborne polyurethane. Phosphorus-containing groups are introduced into a soft segment of a polyurethane molecular chain by adopting phosphorus-containing polyol shown as the formula (1) to form a part of a waterborne polyurethane structure unit, so that the waterborne polyurethane structure unit has flame retardance under the condition that a flame retardant is not added; by adopting the phosphorus-containing stabilizer as shown in the formula (2), emulsification of phosphorus-containing waterborne polyurethane can be promoted, and the problem that emulsion is unstable after chain extension is solved, so that the problems that when a phosphorus-containing group is introduced into a polyurethane molecular structure, emulsification is difficult, and a waterbornedispersion liquid is difficult to form are solved. Moreover, phosphine-containing groups are introduced into the soft segment, the stabilizer and the chain extender of the waterborne polyurethane, sothat the flame retardance is greatly improved; and meanwhile, the binding power of the waterborne polyurethane is also enhanced by introducing a specific phosphorus-containing structure.

Owner:SHANGHAI DIMU NEW MATERIAL TECH

Illite/smectite clay containing anti-PID functional master batch for photovoltaic packaging film and preparation method for illite/smectite clay containing anti-PID functional master batch

ActiveCN109705442AGood anti-PID functionImprove high temperature resistanceNon-macromolecular adhesive additivesFilm/foil adhesives without carriersMasterbatchSilanes

The invention relates to the field of photovoltaic packaging materials and particularly relates to an illite / smectite clay containing anti-PID functional master batch for a photovoltaic packaging filmand a preparation method for the illite / smectite clay containing anti-PID functional master batch. The master batch is prepared from the following ingredients in percentage by weight: 50% to 88% of EVA resin, 4% to 20% of modified zirconium phosphate crystal, 0.5% to 10% of cross-linker, 0.5% to 2.5% of silane coupler, 5% to 15% of nano illite / smectite clay and the balance of auxiliaries. According to the illite / smectite clay containing anti-PID functional master batch for the photovoltaic packaging film and the preparation method for the illite / smectite clay containing anti-PID functional master batch, the defect in the prior art that master batches for photovoltaic packaging films do not have an anti-PID function and thus performance of batteries is low is overcome; the illite / smectiteclay containing anti-PID functional master batch for the photovoltaic packaging film, prepared by the method, has a good anti-PID function; meanwhile, a top-class flame-retardant effect is achieved under the condition of not additionally adding flame retardants; and furthermore, the illite / smectite clay containing anti-PID functional master batch further has the advantages that the antibacterial and mildewproof effect is good, meanwhile, toxic and harmful substances in the functional master batch can be remarkably reduced, and the like.

Owner:NINGBO NENGZHIGUANG NEW MATERIALS TECH

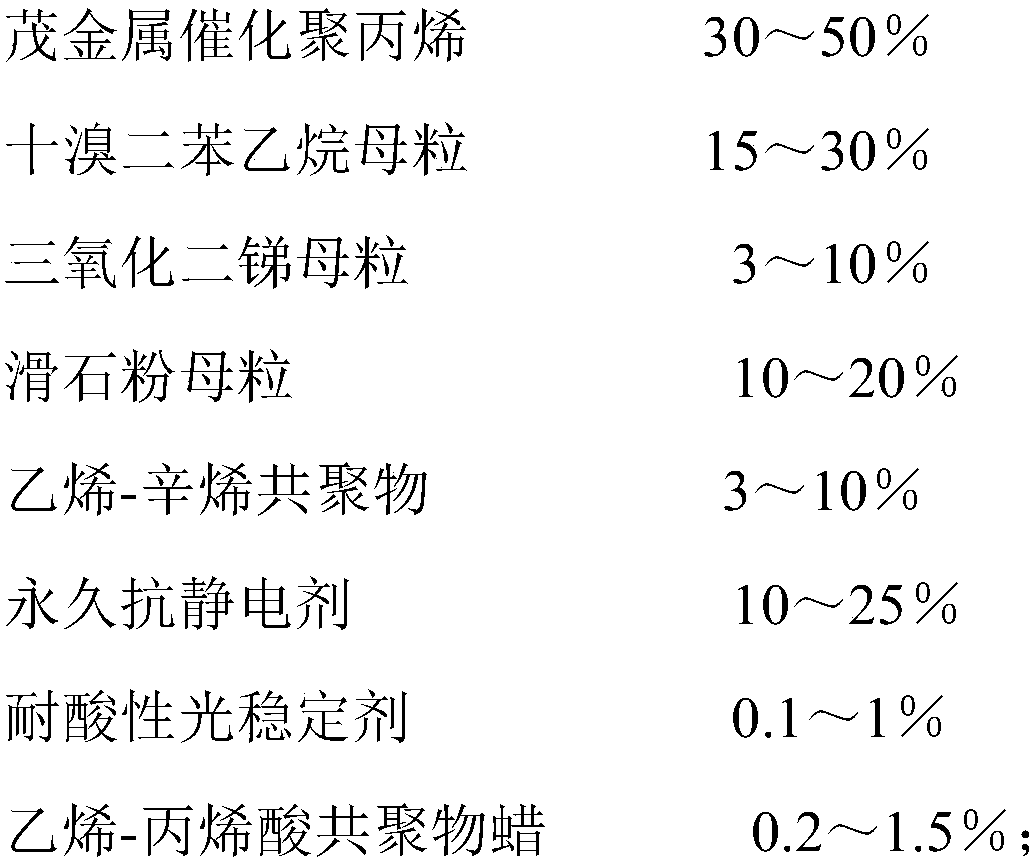

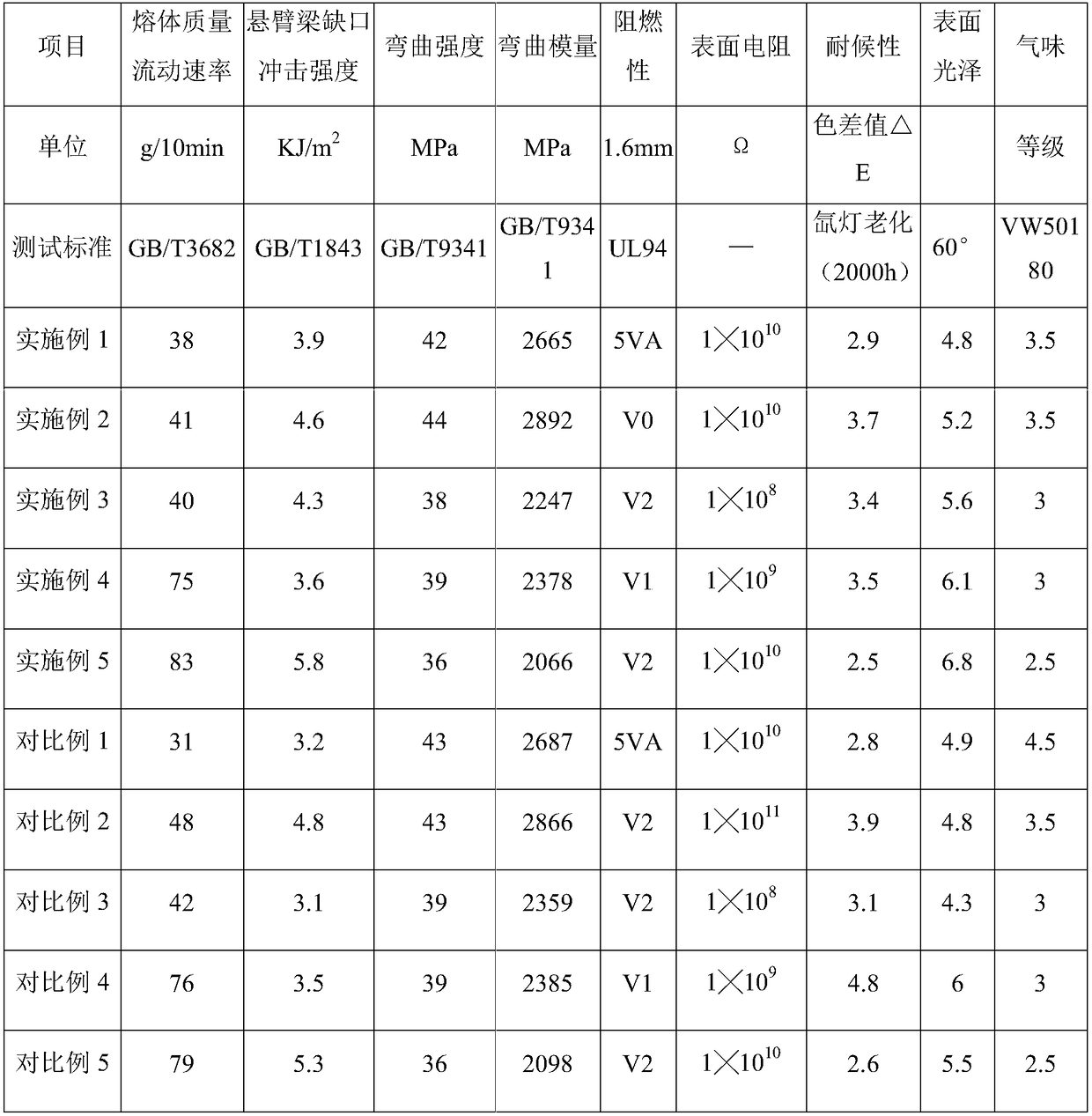

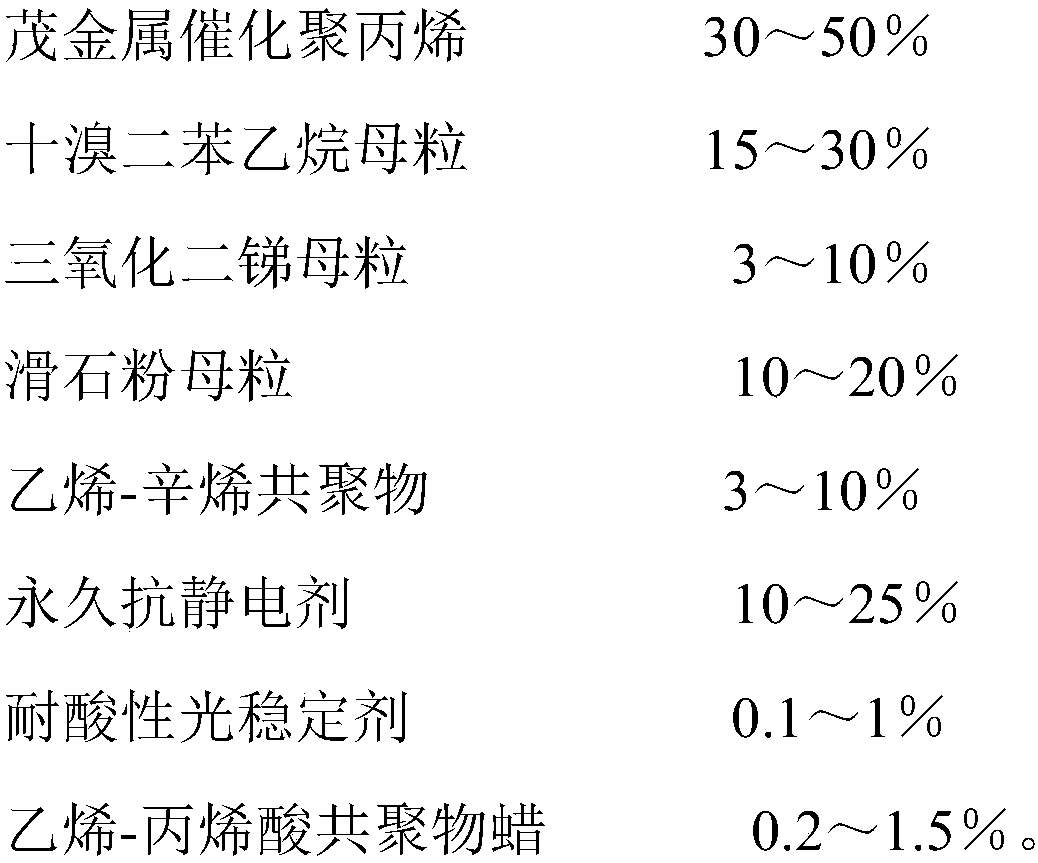

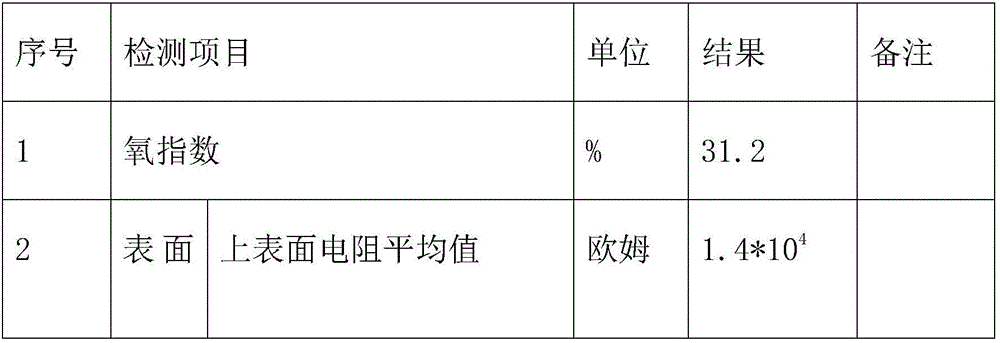

Highly weather-resistant permanent antistatic flame-retardant polypropylene material as well as preparation method and application thereof

The invention belongs to the technical field of improvement of high polymer composite materials and particularly relates to a highly weather-resistant permanent antistatic flame-retardant polypropylene material as well as a preparation method and application thereof. The highly weather-resistant permanent antistatic flame-retardant polypropylene material comprises the following components in percentage by mass: 30-50% of motallocene-catalyzed polypropylene, 15-30% of a decabrominated dipheny ethane master batch, 3-10% of an antimonous oxide master batch, 10-20% of a talcum powder master batch,3-10% of an ethylene-octylene copolymer, 10-25% of a permanent antistatic agent, 0.1-1% of an acid resistant light stabilizer and 0.2-1.5% of ethylene-acrylic acid copolymer wax. The polypropylene material provided by the invention has the characteristics of excellent weather resistance, permanent antistatic property, excellent flame-retardant property, low cost, forming simplicity, balanced physical and mechanical properties, and can be used for preparing a charging pile housing, an electric vehicle battery case, a heater shell or an extension socket shell.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS

Flame-retardant polyamide fiber and preparation method thereof

ActiveCN110923841AImprove spinnabilityImprove mechanical propertiesFlame-proof filament manufactureMonocomponent polyesters artificial filamentPolymer scienceZinc compounds

The invention relates to a flame-retardant polyamide fiber and a preparation method thereof. The preparation method comprises the steps of performing melt blending on polyamide, melamine cyanurate, graphite-like carbon nitride, a zinc compound and a 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO) derivative to prepare a flame-retardant polyamide slice, performing melt spinning and drafting winding, or performing melt blending on the substances to prepare flame-retardant masterbatch, adding 8.25-25wt% of the flame-retardant masterbatch in a direct spinning process of the polyester slice or a melt to perform melt spinning and drafting winding, wherein the prepared flame-retardant polyamide fiber is made from the flame-retardant polyamide, and in parts by mass, the flame-retardant polyamide is mainly composed of 92-95.8 parts of the polyamide, 1-2 parts of the melamine cyanurate, 0.1-0.5 parts of the graphite-like carbon nitride, 0.1-0.5 parts of the zinc compound and 3-5 partsof the DOPO derivative. The preparation process is simple, and the prepared flame-retardant polyamide fiber has the relatively good mechanical property and flame retardant property.

Owner:上海力道新材料科技股份有限公司

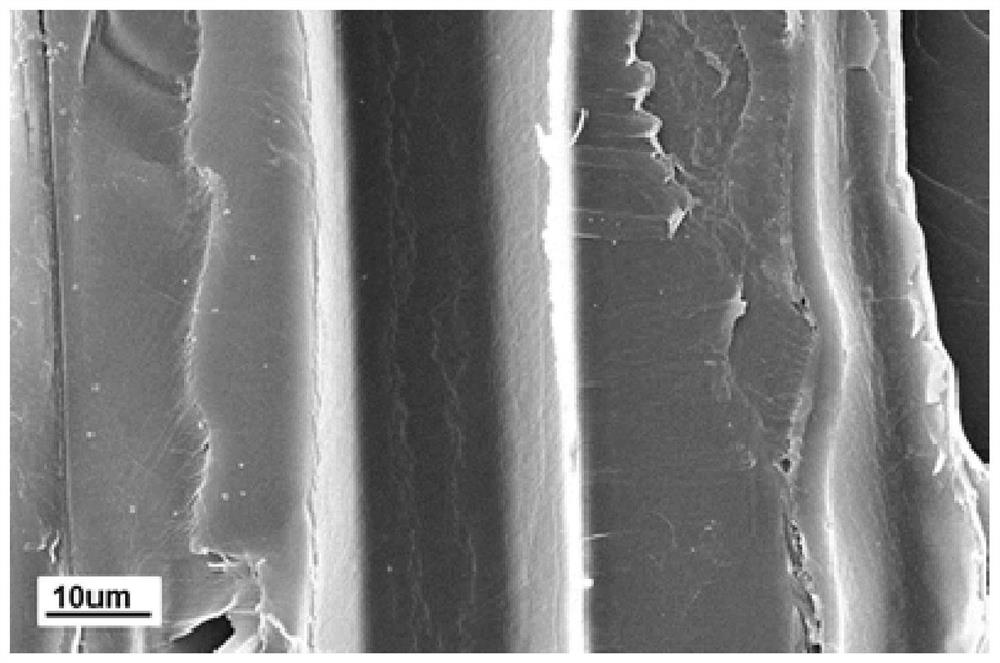

Preparation method for organic silicon and graphene oxide synergistic flame retardant polymer composite material

ActiveCN106832389AEfficient flame retardant and fireproof effectHigh flame retardant efficiencyCoatingsPolymer scienceTemperature resistance

The invention relates to the field of a polymer composite material, in order to solve the problems of inferior fireproof safety, anti-ageing effect and inflammable property of most polymer materials. The invention provides a preparation method for an organic silicon and graphene oxide synergistic flame retardant polymer composite material. According to a method for respectively wrapping graphene oxide and organic silicon resin on the surface of a flammable polymer material, the excellent high temperature resistance and synergistic flame retardant effect of the graphene oxide and organic silicon resin are utilized to realize the efficient flame retardant fireproof property of the flammable polymer material, and meanwhile, the physical properties of the polymer material are effectively maintained.

Owner:HANGZHOU NORMAL UNIVERSITY

Halogen-free fire-retardant foam and preparation method thereof

InactiveCN109485899AImprove flame retardant performanceHigh smoke suppression effectBuilding insulationsMaterials preparationCombustion

The invention discloses a halogen-free fire-retardant foam and relates to the technical field of foam material preparation. According to the technical scheme, the halogen-free fire-retardant foam is characterized by including, by weight part, 52-62 parts of toluene diisocyanate, 45-55 parts of polypropylene glycol, 45-55 parts of polyether polyol, 4.1-5.1 parts of water, 0.1-0.2 part of polyurethane catalyst, 0.1-0.5 part of organo-tin catalyst, 0.8-1.6 parts of foam stabilizer, 6-10 parts of auxiliary foaming agent and 8-12 parts of halogen-free fire-retardant agent. The halogen-free fire-retardant foam solves the problem that foams are inflammable, high in smokiness and prone to producing toxic and hazardous gas during combustion; the halogen-free fire-retardant agent can improve the fire resistance of the halogen-free fire-retardant foam and ensure that the halogen-free fire-retardant foam can be low in smokiness and free from toxic and hazardous gas during combustion.

Owner:青岛世林新海绵有限公司

Organic montmorillonite/halogen-free diphosphonate fire retardation PA6T/6 composite material and preparation method thereof

The present invention relates to a semi-aromatic PA6T / 6 composite material, particularly to an organic montmorillonite (OMMT) / halogen-free diphosphonate fire retardation PA6T / 6 composite material and a preparation method thereof. The organic montmorillonite (OMMT) / halogen-free diphosphonate fire retardation PA6T / 6 composite material comprises, by mass, 20-200 parts of a PA6T / 6 resin, 5-50 parts of a halogen-free diphosphonate fire retardation agent, and 1-10 parts of organic montmorillonite. The fire retardation composite material of the present invention has characteristics of high fire retardation efficiency, halogen-free fire retardation, green environmental protection, low harm on human health, low environment pollution, high fire retardation grade, and significant effect.

Owner:JUNMA TIRE CORD

Preparation method of compound flame-retardant wood

ActiveCN114147825AWon't releaseNo pollutionWood treatment detailsPretreatment apparatusPolymer scienceSodium silicate

The invention discloses a preparation method of compound flame-retardant wood, and belongs to the technical field of wood flame retardance. The invention aims to solve the problems of poor flame retardant effect of boric acid and poor loss resistance of wood treated by sodium silicate in the prior art. The preparation method comprises the following steps: I, impregnating wood with silicate; and 2, boric acid dipping. The method is used for preparing the compound flame-retardant wood.

Owner:NORTHEAST FORESTRY UNIVERSITY

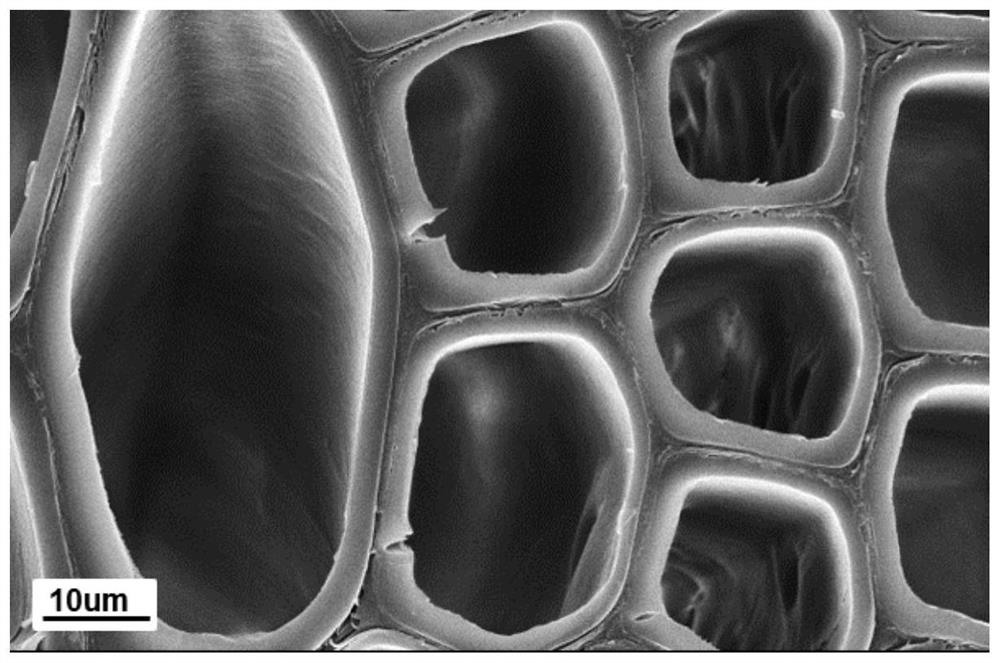

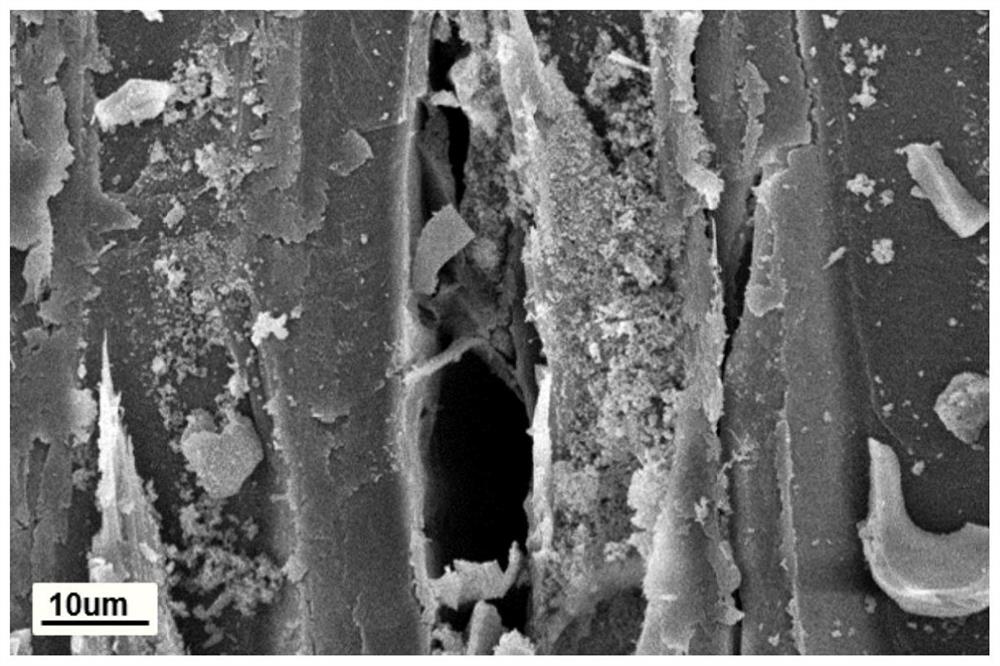

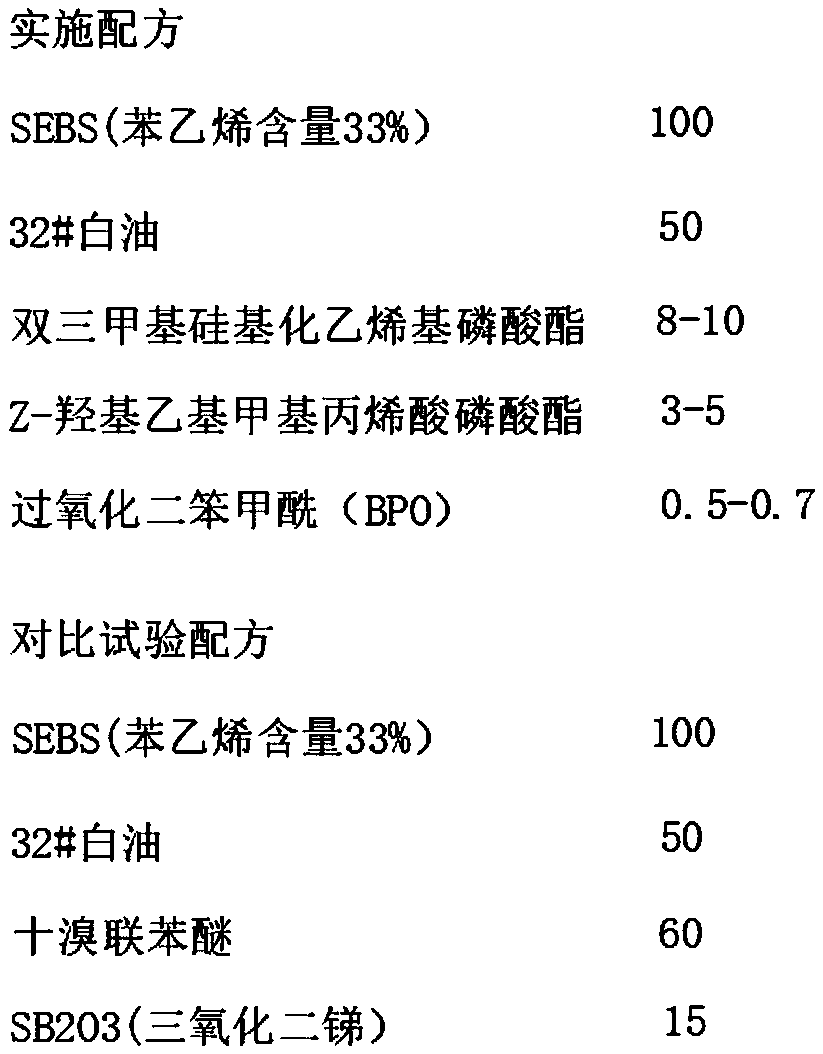

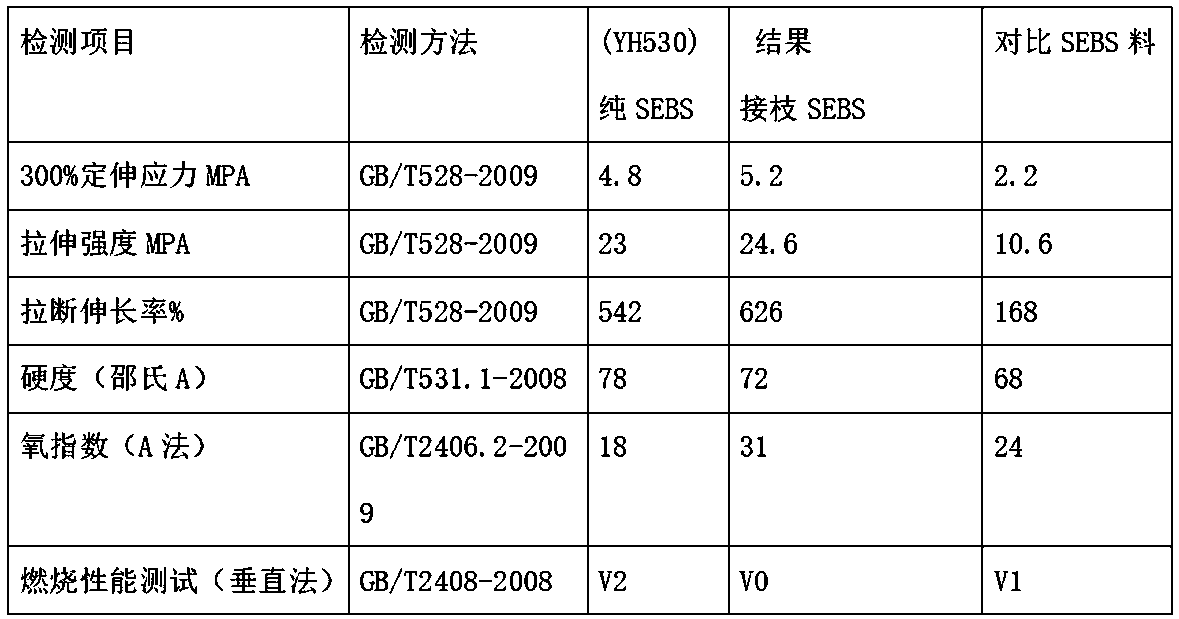

High-performance flame-retardant SEBS graft polymer and preparation method thereof

InactiveCN110229287AImprove mechanical propertiesImprove flame retardant performanceCarbon layerPolymer science

The invention discloses a high-performance flame-retardant SEBS graft polymer and a preparation method thereof, and belongs to the technical field of graft polymer preparation. A twin-screw extruder is adopted for the method of a melt grafting reaction. Due to the existence of silicon and phosphorus in the SEBS molecule of a SEBS polymer prepared after the graft reactive extrusion and since the silicon and phosphorus have excellent synergistic flame retardant effect, carbonization of the SEBS flame-retardant system and compactness and flame retardancy of the carbon-layer structure are greatlyimproved. Thereby, the prepared SEBS polymer has high flame retardant property, and high mechanical properties of the SEBS can be maintained. The screw of the twin-screw extruder is provided with a mutation section, and the mutation section adopts a variable-diameter and variable-lead structure. When a material is being heated to the highest temperature in the mutation section, the material is compressed, and throughput of the material is reduced. Thereby, less heating is realized, the material is promoted to be fully heated, and the heating effect of the material is enhanced. And then, the quality of the extruded product is improved, and performance optimization of the material is realized.

Owner:JIANGSU HENGFENG CABLE

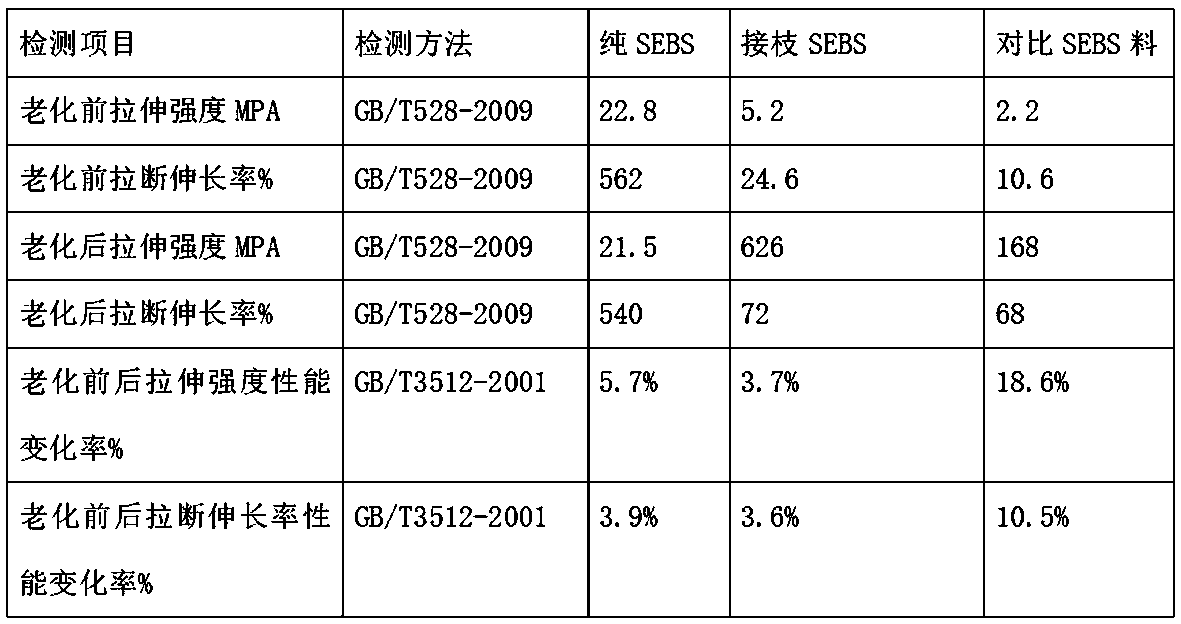

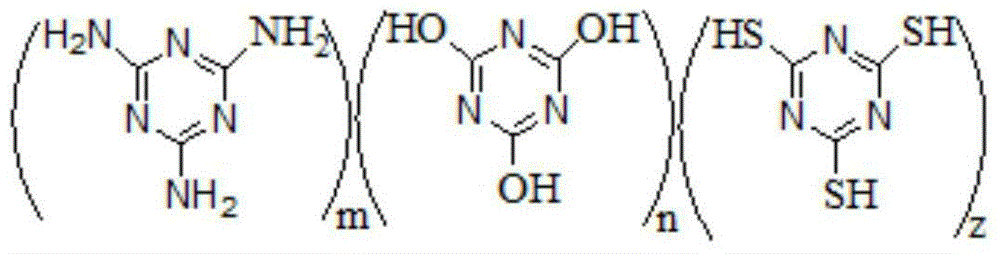

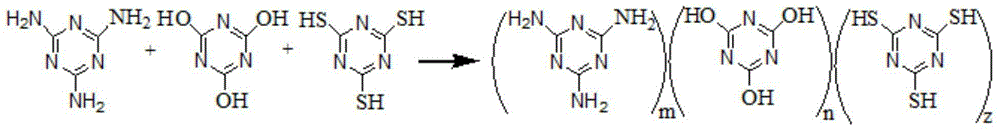

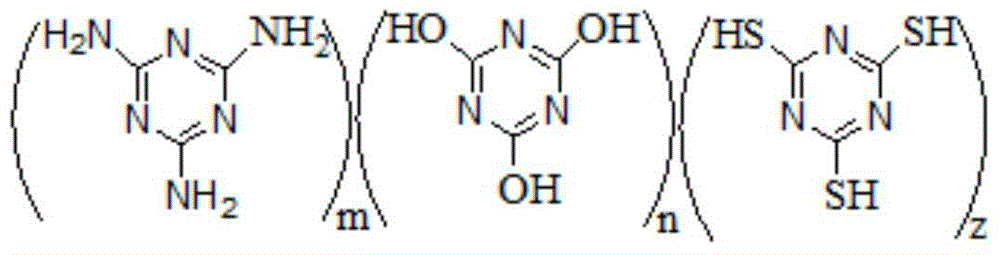

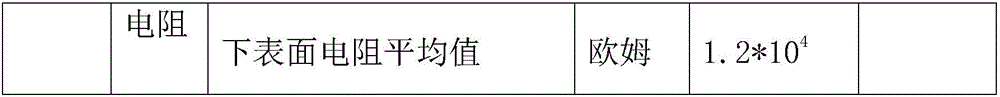

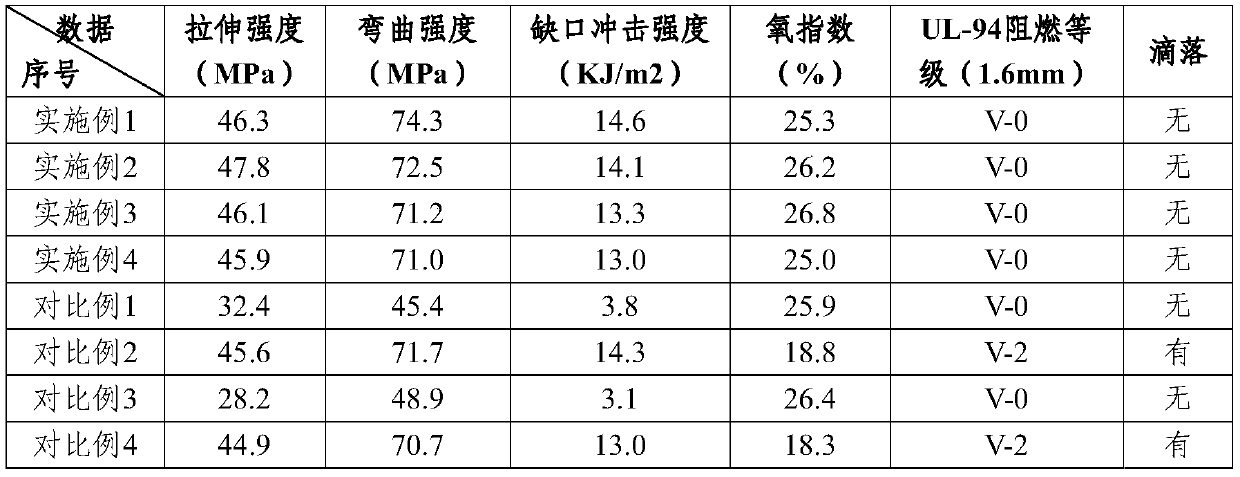

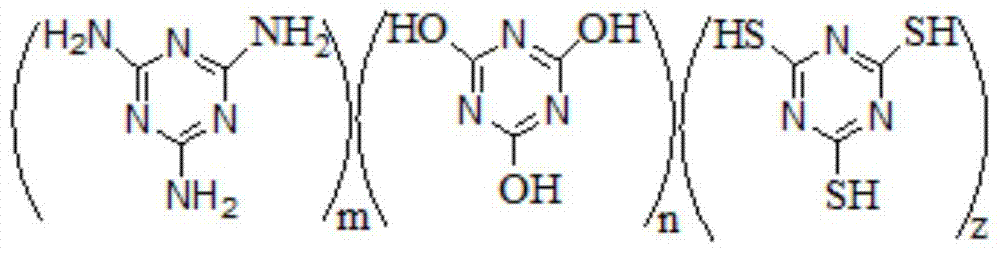

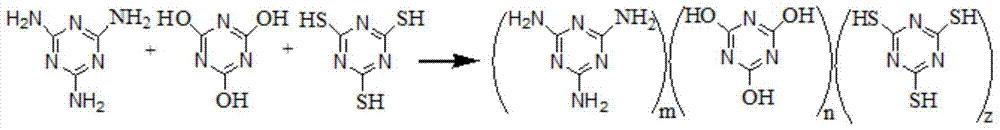

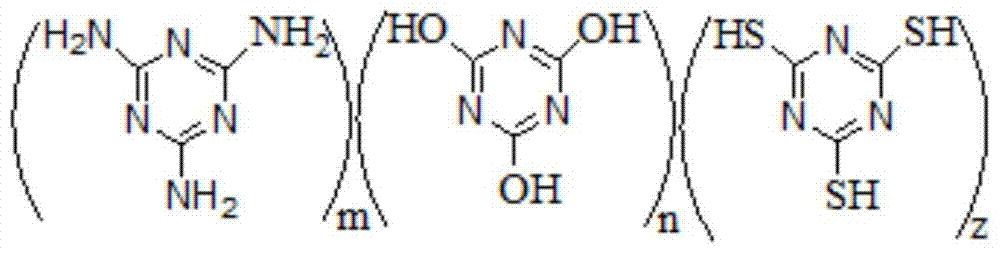

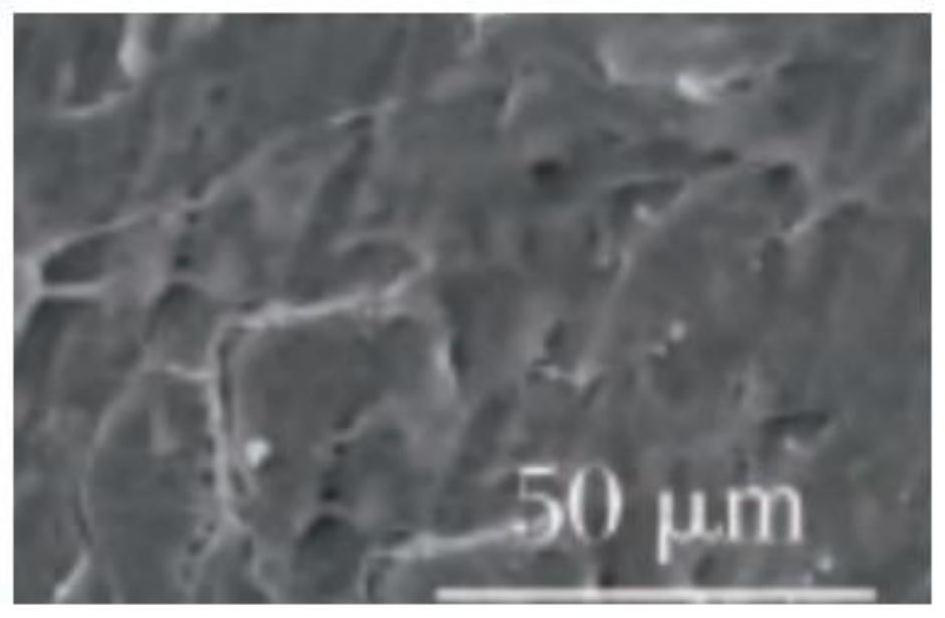

Modified melamine cyanurate fire retardant and preparation method thereof

ActiveCN104530478AEffective dispersionReduce the ratioOrganic chemistryCyanuric acidThermal stability

The invention relates to a modified melamine cyanurate fire retardant and a preparation method thereof, and belongs to the field of preparation of a fire retardant polymer material. The preparation method comprises the following steps: modifying trithiocyanuric acid, adding and stirring melamine, cyanuric acid, trithiocyanuric acid and water in certain proportion into a reaction kettle to obtain a mixture I, keeping the reaction of the mixture I for 1 to 5 hours at the temperature of 80 to 150 DEG C to obtain viscose paste of modified melamine cyanurate, and filtering, drying and crushing the viscose paste of the modified melamine cyanurate to obtain modified melamine cyanurate, wherein the structure formula of the modified melamine cyanurate is as shown in the specification. Compared with the traditional melamine cyanurate, the modified melamine cyanurate has the characteristics of good thermal stability, high fire retardant efficiency, good dispersion property, high char yield, excellent comprehensive performance and the like.

Owner:DONGHUA UNIV

Halogen-free flame-retardant polypropylene composite material and preparation method thereof

The invention discloses a halogen-free flame-retardant polypropylene composite material and a preparation method thereof. The halogen-free flame-retardant polypropylene composite material includes, byweight, 100 parts of a polypropylene resin, 10-30 parts of a glass fiber, 1-6 parts of modified graphene, 3-10 parts of modified magnesium hydroxide, 0.5-2 parts of polypropylene wax and 0.1-1 part of an antioxidant. The addition of the modified graphene and modified magnesium hydroxide to the polypropylene composite material system obviously enhances the flame retardant effect of the composite material, the modified graphene and modified magnesium hydroxide have obvious cooperative flame retardant effects, and the modified graphene and modified magnesium hydroxide have good compatibility with the polypropylene resin, and slightly affect the mechanical properties of the polypropylene resin, and the addition of the glass fiber greatly enhances the mechanical properties of the composite material.

Owner:安庆市泽烨新材料技术推广服务有限公司

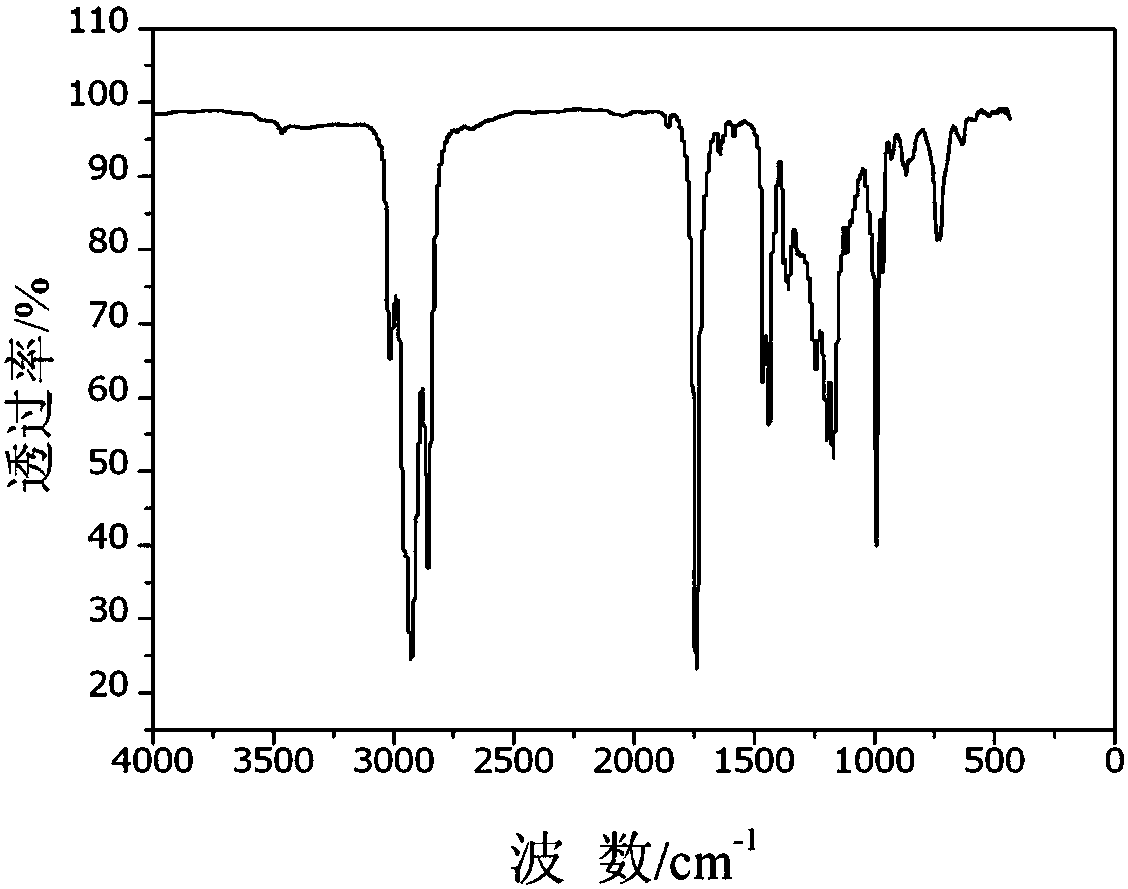

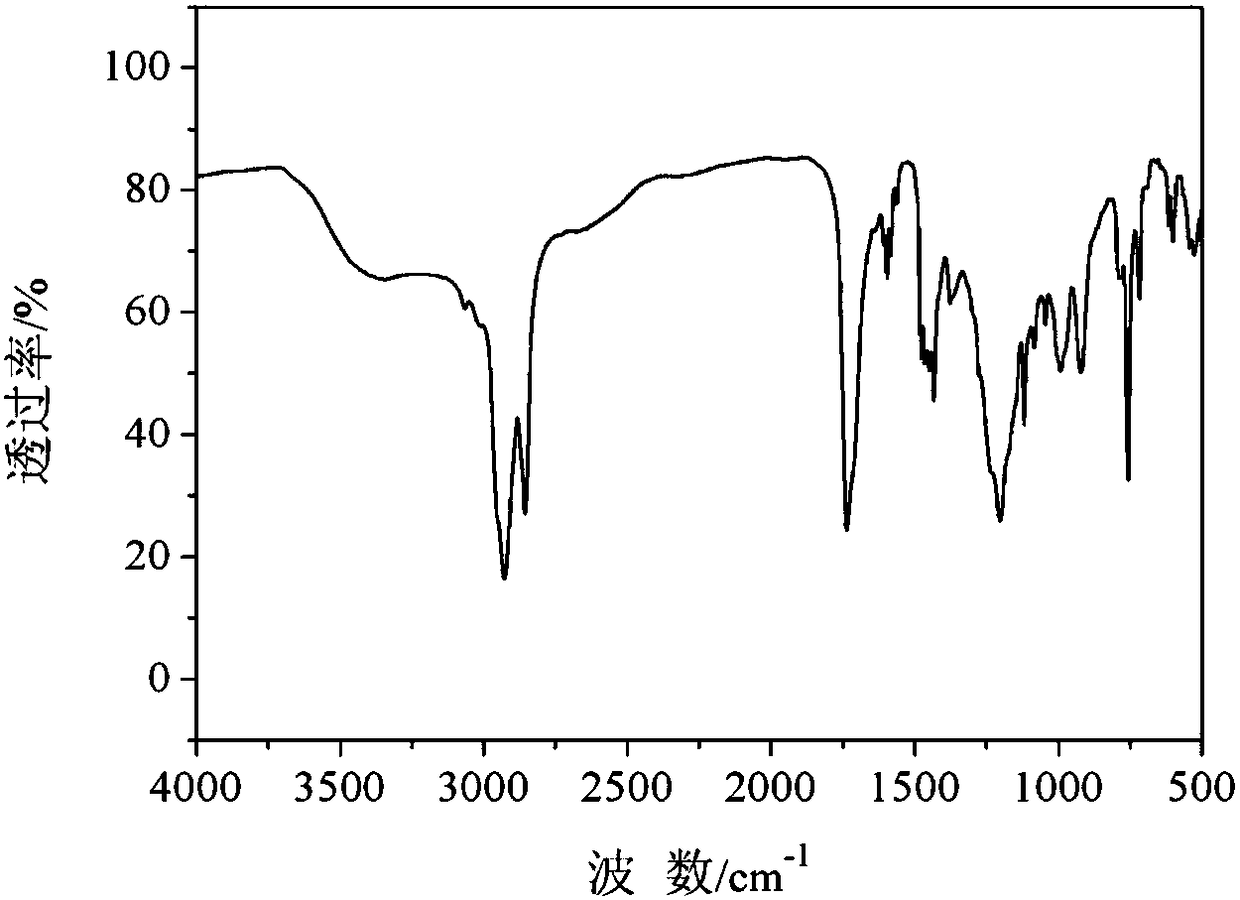

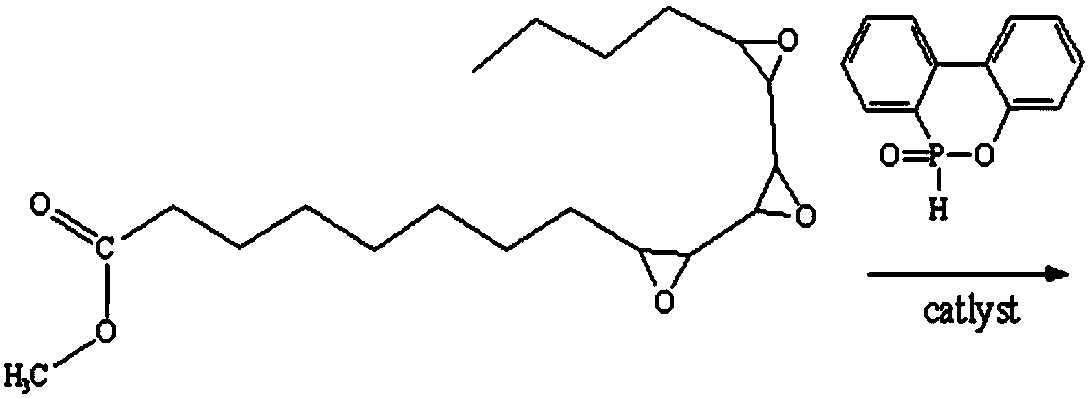

Phosphorus-containing vegetable oil-based flame-retardant polyol and its preparation method and application

ActiveCN106349290BGood storage stabilityGood compatibilityGroup 5/15 element organic compoundsVegetable oilPhosphate

The invention relates to phosphorus-containing vegetable oil based flame-retardant polyol and a preparation method and application thereof. The preparation method of the phosphorus-containing vegetable oil based flame-retardant polyol comprises the following steps: carrying out epoxide reaction on tung oil methyl ester with hydrogen peroxide and methanoic acid under the catalyzing effect of a home-made phase transfer catalyst at first to prepare multi-functionality-degree epoxidized tung oil methyl ester; reacting the obtained epoxidized tung oil methyl ester with reactive-hydrogen-containing DOPO (DOPO belongs to phosphorus-containing phenanthrene ring and heterogeneous ring compound, and the full name of DOPO is 9,10-diamine-9-oxygen heterocyclic-10- phosphaphenanthrene-10-oxide) to obtain the phosphorus-containing vegetable oil based flame-retardant polyol. The obtained polyol is a flame retardant, the synthesized structural flame-retardant vegetable oil based polyol is used in hard polyurethane flame-retardant foam, mechanical strength and flame retardance of the foam are improved, and a preparation process is simple, convenient to operate and easy to obtain. The phosphorus-containing vegetable oil based flame-retardant polyol is compounded with tris( 2-chloropropyl) phosphate, phosphorus-nitrogen synergistic flame retardant effect is good, the use amount of a flame retardant can be reduced, the flame retardant effect is much better than the flame retardant effect of the tris( 2-chloropropyl) phosphate which is used independent, and the oxygen index (LOI) can reach 29%.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Production process of reactive flame retardant polyester fabric

InactiveCN109097981AImprove flame retardant performanceImprove poor washing performanceHeat resistant fibresPolyesterChemistry

The invention discloses a production process of a reactive flame retardant polyester fabric. The production process includes the following steps: the step A of washing the polyester fabric with acetone and drying at 55-65 DEG C for 40-60 minutes to obtain a product a; the step B of soaking the product a in a flame retardant liquid to obtain a product b with the soaking temperature of 35-40 DEG C and the soaking time of 30-40 min, wherein the bath ratio between the product a and the flame retardant liquid is 1:8; the step C of squeezed the product b to obtain a product c; the step D of pre-drying the product c to obtain a product d with the pre-drying temperature of 70-80 DEG C and the time of 1-3min; the step E of baking the product d to obtain a product e with the baking temperature of 130-140 DEG C and the time of 2-3min; the step F of cooling the product e to room temperature to obtain a final product. The production process has the advantages of being able to effectively improve the flame retarding effect.

Owner:ZHEJIANG CADY IND

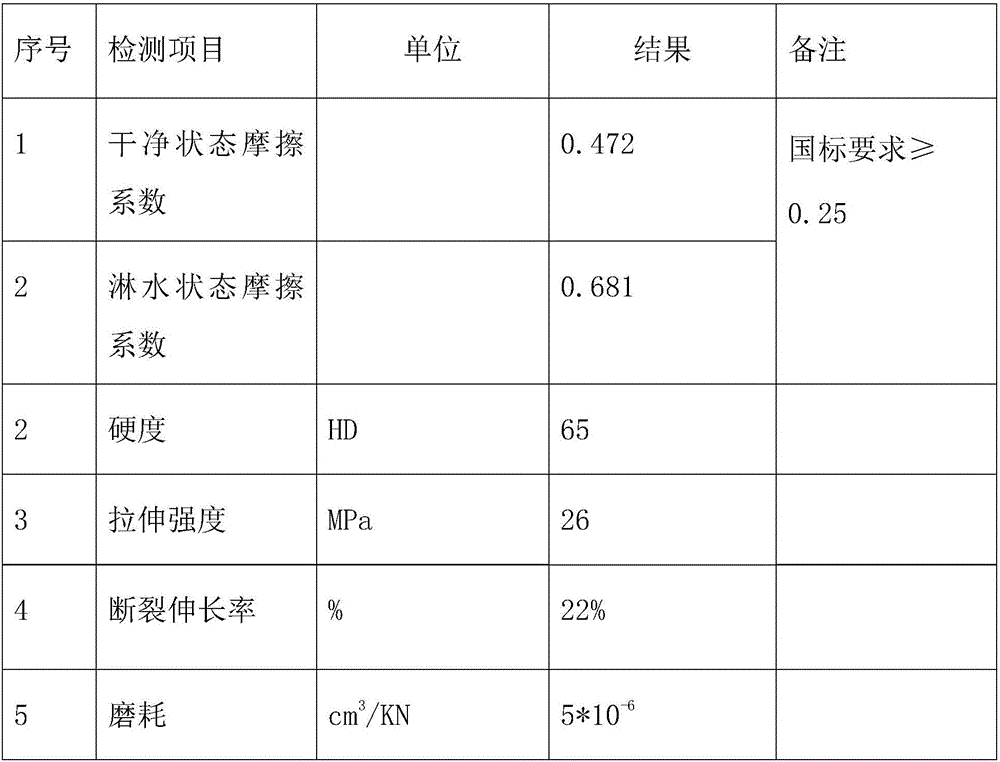

Flame-retarding and antistatic friction liner for elevator and preparation method of flame-retarding and antistatic friction liner

InactiveCN106751435AIncrease coefficient of frictionLower the resistance valueStearic acidAccelerant

The invention provides a flame-retarding and antistatic friction liner. The flame-retarding and antistatic friction liner is prepared from the following raw materials in parts by weight: 100 to 250 parts of cashew nut oil modified phenol formaldehyde resin, 5 to 30 parts of rubber powder, 10 to 20 parts of calcium sulfate whiskers, 10 to 30 parts of an antistatic agent, 10 to 20 parts of barium sulfate, 5 to 10 parts of bronze powder, 5 to 10 parts of iron powder, 1 to 10 parts of a toner, 1 to 5 parts of a coupling agent, 2 to 5 parts of wollastonite, 1 to 10 parts of sulfur, 3 to 5 parts of zinc oxide, 0 to 2 parts of stearic acid, 10 to 50 parts of hydrogenated nitrile butadiene rubber, 5 to 15 parts of micro-encapsulated red phosphorus, 5 to 30 parts of ammonium polyphosphate, 10 to 20 parts of dibutyl phthalate, 1 to 3 parts of an accelerant M, 0.5 to 1 part of an accelerant TMTD (Tetramethylthiuram Disulfide), 1 to 5 parts of an accelerant H and 1 to 3 parts of an antioxidant 1010. The invention further provides a preparation method. The flame-retarding and antistatic friction liner has stable friction coefficient, high strength and low abrasion loss, and flame-retarding and antistatic properties.

Owner:王利英 +1

ABS flame-retardant composite material prepared by using acrylic artificial stone waste materials and preparation method thereof

The invention discloses an ABS flame-retardant composite material prepared by using acrylic artificial stone waste materials and a preparation method thereof. The ABS flame-retardant composite material comprises (by weight): 100 parts of dry ABS resin, 5-40 parts of modified acrylic artificial stone waste powder, 4-10 parts of a compatilizer, 5-25 parts of a flame retardant, 0.5-1 part of a lubricant and 0.5-1 part of an antioxidant. The modified acrylic artificial stone waste powder is obtained after acrylic artificial stone waste powder undergoes surface treatment by using a coupling agent.It is ensured that the ABS composite material has excellent flame retardant property and mechanical properties. According to the ABS flame-retardant composite material, latent resource attributes of acrylic artificial stone waste materials are fully utilized, and the problem of solid wastes generated by acrylic artificial stone waste materials is solved. The ABS flame-retardant composite materialhas good economic and social meaning. The preparation method comprises the following steps: pretreatment of raw materials, premixing of raw materials, and preparation of the ABS flame-retardant composite material. The preparation method has simple operation steps, has strong practicality, and is easy for industrial implementation and promotion and application.

Owner:CHANGZHOU VOCATIONAL INST OF ENG

A kind of environment-friendly fireproof material for electric equipment and preparation method thereof

ActiveCN106497339BExcellent Melt Flow RateHigh flame retardant efficiencyFireproof paintsEpoxy resin coatingsFiberCrack resistance

The invention provides an environment-friendly fireproof material for electrical equipment and a preparation method of the environment-friendly fireproof material, and belongs to the fields of fireproof materials and preparation technologies thereof. The environment-friendly fireproof material for the electrical equipment is characterized by being prepared from the following raw materials in parts by weight: 50 to 60 parts of modified epoxy resin, 30 to 40 parts of fluorocarbon resin, 60 to 90 parts of a fire retardant, 3 to 10 parts of expanded graphite, 3 to 10 parts of alumina silicate fiber and 2 to 8 parts of molecular sieves. The fireproof material provided by the invention is applied to fire protection of the electrical equipment, and is high in crack resistance, water resistance and weather resistance and good in expansion character; meanwhile, the heat release rate of a base material in a burning condition can be obviously reduced, and the quality loss is reduced; moreover, the fireproof material is small in smoke production quantity and good in environmental protection effect.

Owner:STATE GRID HENAN ELECTRIC ZHOUKOU POWER SUPPLY

A kind of modified melamine cyanurate flame retardant and preparation method thereof

ActiveCN104530478BEffective dispersionReduce the ratioOrganic chemistryCyanuric acidThermal stability

The invention relates to a modified melamine cyanurate fire retardant and a preparation method thereof, and belongs to the field of preparation of a fire retardant polymer material. The preparation method comprises the following steps: modifying trithiocyanuric acid, adding and stirring melamine, cyanuric acid, trithiocyanuric acid and water in certain proportion into a reaction kettle to obtain a mixture I, keeping the reaction of the mixture I for 1 to 5 hours at the temperature of 80 to 150 DEG C to obtain viscose paste of modified melamine cyanurate, and filtering, drying and crushing the viscose paste of the modified melamine cyanurate to obtain modified melamine cyanurate, wherein the structure formula of the modified melamine cyanurate is as shown in the specification. Compared with the traditional melamine cyanurate, the modified melamine cyanurate has the characteristics of good thermal stability, high fire retardant efficiency, good dispersion property, high char yield, excellent comprehensive performance and the like.

Owner:DONGHUA UNIV

Synergic flame retardance asphalt material and preparation method thereof

InactiveCN102604396BSynergistic flame retardant effect is goodOther app performance improvementsBuilding insulationsHalogenAging resistance

The invention discloses a synergic flame retardance asphalt material, which is characterized in that the asphalt material is prepared by mixing the following raw materials in parts by weight: 100 of asphalt, 0.2-40 of metal hydroxide, 0.1-30 of layered silicate; the asphalt is one or more of petroleum asphalt, rock asphalt and coal pitch; and the metal hydroxide is aluminum hydroxide and / or magnesium hydroxide. The invention also provided a preparation method of the synergic flame retardance asphalt material. According to the invention, the synergic flame retardance function of the metal hydroxide and the layered silicate is utilized to perform nano composite modification on asphalt; compared with the common organic flame retardant (such as a halogen flame retardant), the flame retardance technique adopted by the synergic flame retardance asphalt material is a green, non-toxic and environmentally friendly flame retardance technique; and the various road performances of the flame retardance asphalt material are good, the use requirements are met, the period of the storage stability can reach above one year, and the temperature sensitivity and the ageing resistance are obviously better than those of common asphalt.

Owner:CHANGAN UNIV

Halogen-free flame-retardant composite material and preparation method thereof

ActiveCN101942128BStrong alkaline catalysisLow water solubilitySynthetic resin layered productsMetal layered productsElastomerPhosphate

The invention provides a halogen-free flame-retardant composite material and a preparation method thereof, and the halogen-free flame-retardant composite material comprises 10%-40% (by weight) of polyethylene, 4.5%-20% (by weight) of elastomer, 40%-70% (by weight) of halogen-free flame retardant, 0.5%-15% (by weight) of flame-retardant synergist and 1%-5%( by weight) of lubricant according to thetotal weight of the composite material, wherein the flame-retardant synergist is selected from one or more of melamine, melamine cyanurate and melamine high molecular weight phosphate. The preparation method comprises the step of carrying out melt compounding on the polyethylene, the elastomer, the halogen-free flame retardant, the flame-retardant synergist and the lubricant through an extruding machine. The halogen-free flame-retardant composite material has the advantage of novel property, environmental protection, safety, excellent flame retardance, good anti-melt droplet effect, good toughness, excellent molding and processing performance and the like, and can achieve the UL-94V-0 (the plate thickness is 4mm) flame retardant level, thereby being particularly applicable to preparing halogen-free flame-retardant aluminum-plastic composite plates.

Owner:FOSHAN SANSHUI JINGE NEW MATERIALS CO LTD

Waterborne polyurethane PE/POE (Polyethylene/Polyolefin Elastomer) composite waterproof coiled material as well as preparation method and application thereof

PendingCN114836140AImprove flame retardant performanceHigh mechanical strengthRoof covering using flexible materialsPolyureas/polyurethane adhesivesElastomerPolymer science

The invention discloses a waterborne polyurethane PE / POE composite waterproof coiled material and a preparation method and application thereof. The waterborne polyurethane PE / POE composite waterproof coiled material comprises a waterborne polyurethane adhesive, a PE / POE composite film base (1) and a protective liner (2), the waterborne polyurethane adhesive is uniformly coated on a single face of the PE / POE composite film base (1), the edge of the PE / POE composite film base (1) is provided with a gap, the coating thickness is 0.1 mm-0. 3mm, and a waterborne polyurethane PE / POE composite film (a) is formed through compounding; and uniformly coating the self-adhesive glue on the margin at the edge of the PE / POE polymeric membrane (a), and compounding the PE / POE polymeric membrane (a) with the protective liner (2) to form the waterborne polyurethane PE / POE composite waterproof coiled material with the total thickness of 0.6-1.5 mm, wherein the coating thickness is 0.1-0.3 mm. The waterborne polyurethane PE / POE composite waterproof coiled material prepared by the invention has the properties of flame retardance, high toughness, high elasticity, high strength, high elongation, high puncture resistance strength, good low-temperature property, chemical resistance and the like, and also has the characteristics of environment friendliness, no pollution, simplified construction process and the like.

Owner:合肥中科凯辰新材料有限公司

Silicious fire retard ant for polyolefin and its prepn and application

The present invention provides one kind of silicious fire retardant for polyolefin with the molecular structure as shown. The fire retardant is white or yellowish powder and has smelting temperature of 220-260 deg.c. The present invention provides the preparation process of the silicious fire retardant and the application of the silicious fire retardant as halogen-free environment fire retarding additive for polyolefin material.

Owner:SOUTH CHINA UNIV OF TECH

A kind of aluminosilicate nanotube, flame-retardant composite material and preparation method thereof

ActiveCN111762792BUniform particle sizeSmall diameterAluminium silicatesNanotechnologyPhthalic acidPhthalate

The present invention proposes a kind of aluminosilicate nanotube, flame-retardant composite material and preparation method thereof, aluminosilicate nanotube adopts Al(NO 3 ) 3· 9H 2 O and tetraethyl orthosilicate preparation, flame-retardant composite material, is made up of the raw material of following weight part: PVC resin 100 parts, dioctyl phthalate 35-45 parts, stabilizer 3-6 parts, lubricant 0.4 ‑0.6 part and 5 parts of flame retardant, the flame retardant includes 0.1‑0.4 part of the described aluminosilicate nanotube and 4.6‑4.9 part of Sb 2 o 3 . The invention simplifies the preparation process of the aluminosilicate nanotube, shortens the production cycle, optimizes the preparation process, and the flame-retardant composite material has good flame-retardant and smoke-suppressing effects and mechanical properties.

Owner:超精(苏州)航空精密机械制造有限公司

Red phosphorus master batch flame retardation PTT polyester and preparation method therefor

InactiveCN104861503AImprove flame retardant performanceSynergistic flame retardant effect is goodPolyesterGlass fiber

The invention discloses a red phosphorus master batch flame retardation PTT polyester and a preparation method therefor. The red phosphorus master batch flame retardation PTT polyester comprises the following ingredients, by weight, 60%-80% of PTT, 10%-15% of red phosphorus master batch, 8%-15% of glass fibers, 2%-8% of POE, 1%-4% of calcium oxide, 0.1%-0.5% of aluminum titanium composite coupling agents, 0.1%-0.5% of anti-oxidants and 0.1%-1% of lubricants. The calcium oxide is calcium oxide particles with a particle size of being less than 5 micrometers. The beneficial effects are that the red phosphorus master batch is employed as a flame retardant, the flame retardation of PTT is raised, and the tensile strength, the bending strength and the CTI value of PTT are also raised obviously; a proper amount of calcium oxide is added for strengthening, a proper amount of POE is added for toughening, calcium oxide and the red phosphorus master batch has good flame retardant synergism effects, and the cost is lowered.

Owner:QINGDAO XINZHAN PLASTIC

A preparation method of organosilicon and graphene oxide synergistic flame retardant polymer composite material

ActiveCN106832389BEfficient flame retardant and fireproof effectHigh flame retardant efficiencyCoatingsPolymer scienceTemperature resistance

The invention relates to the field of a polymer composite material, in order to solve the problems of inferior fireproof safety, anti-ageing effect and inflammable property of most polymer materials. The invention provides a preparation method for an organic silicon and graphene oxide synergistic flame retardant polymer composite material. According to a method for respectively wrapping graphene oxide and organic silicon resin on the surface of a flammable polymer material, the excellent high temperature resistance and synergistic flame retardant effect of the graphene oxide and organic silicon resin are utilized to realize the efficient flame retardant fireproof property of the flammable polymer material, and meanwhile, the physical properties of the polymer material are effectively maintained.

Owner:HANGZHOU NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com