Silicious fire retard ant for polyolefin and its prepn and application

A silicon flame retardant and polyolefin technology, which is applied in the field of silicon-containing flame retardant for polyolefin and its preparation, can solve the problems of damage to the mechanical properties of polyolefin materials, unsatisfactory flame retardant effect, unfavorable production and application, and the like, Achieve the effect of improving compatibility, good flame retardant and synergistic flame retardant effect, and reducing the impact of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

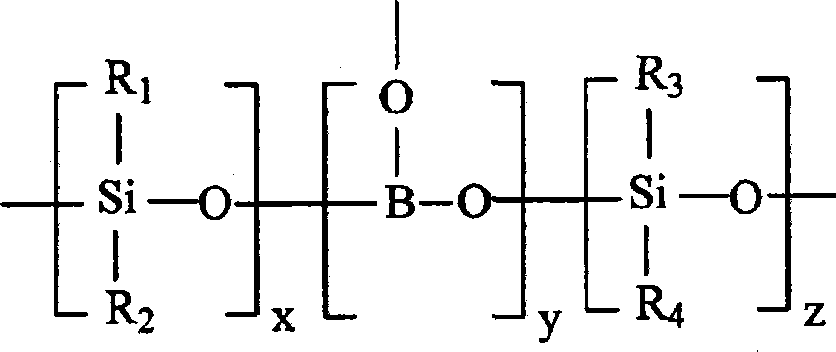

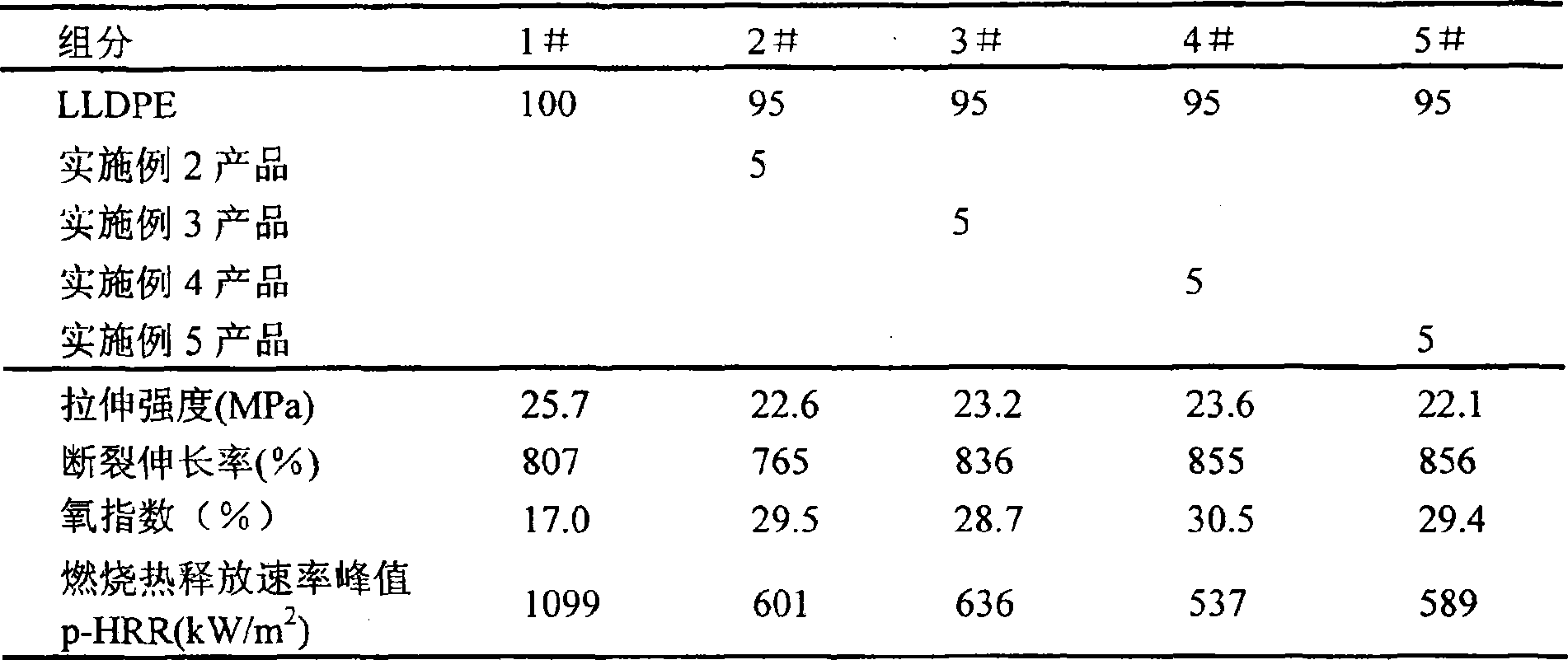

[0024] When equipped with mechanical stirring, water separator and condenser, N 2 In the 500mL dry four-necked flask of the catheter, feed dry nitrogen to remove the air in the flask, then add 4.4g glycerol monostearate, 23.0g tributyl borate, 44.0g diphenyl dihydroxysilane, 3.6g Vinyltrimethoxysilane, 1.2g of dibutyltin dilaurate and 250mL of anhydrous toluene were stirred evenly, then gradually heated up to 110°C and refluxed for 4 hours, then heated up to 180°C to continue the reaction for 1 hour, and a light yellow solid was obtained after cooling. After drying, it was pulverized and sieved to obtain a white (slightly light yellow) fine powder with a yield of 88%. The molecular composition formula is: where R 1 is phenyl, R 3 for vinyl, R 4 Part of it is glyceryl monostearate, part of it is methoxy group, the molar content of phenyl group is about 91%; the weight average molecular weight is about 2.2×10 3 ; The melting temperature is 220°C.

Embodiment 2

[0026] When equipped with mechanical stirring, water separator and condenser, N 2 In the 500mL dry four-necked flask of the catheter, pass dry nitrogen into it to remove the air in the flask, then add 4.4g glycerol monooleate, 6.2g boric acid, 44.0g diphenyldihydroxysilane, 3.6g vinyltrimethoxy base silane, 1.2g dibutyltin dilaurate and 250mL anhydrous toluene, after stirring evenly, gradually raise the temperature to 160°C and reflux for 8 hours, then raise the temperature to 250°C and continue the reaction for 1 hour. White (slightly light yellow) fine powder was obtained by sieving with a yield of 96%. The molecular composition formula is: where R 1 is phenyl, R 3 for vinyl, R 4 Part of it is monoolein glyceride group, part of it is methoxy group, the molar content of phenyl group is about 90%; the weight average molecular weight is about 9.5×10 3 ; The melting temperature is 260°C.

Embodiment 3

[0028] When equipped with mechanical stirring, water separator and condenser, N 2 Into a 500mL dry four-neck flask in the catheter, pass dry nitrogen into it to remove the air in the flask, then add 9.0g glycerol monooleate, 6.2g boric acid, 66.0g diphenyldihydroxysilane, 3.6g vinyltrimethoxy silane, 1.7g of dibutyltin dilaurate and 250mL of anhydrous toluene were stirred evenly, then gradually heated up to 120°C and refluxed for 6 hours, and then heated up to 200°C to continue the reaction for 2 hours. After cooling, a light yellow solid was obtained, which was dried in vacuum and crushed. White (slightly light yellow) fine powder was obtained by sieving with a yield of 92%. The molecular composition formula is: where R 1 is phenyl, R 3 for vinyl, R 4 It is a glyceryl monooleate group, the phenyl molar content is about 92%; the weight average molecular weight is about 1.1×10 4 ; The melting temperature is 240°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com