Polypropylene carrier high-efficiency halogen-free flame-retardant master batch and preparation method thereof

A technology of flame retardant masterbatch and polypropylene, which is applied in the field of flame retardant materials, can solve the problems of poor flame retardant effect, large amount of masterbatch added, and decreased mechanical properties of modified materials, achieving uniform dispersion, small repulsion, and Good strengthening and toughening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for preparing a polypropylene carrier high-efficiency halogen-free flame-retardant masterbatch, the specific steps are as follows:

[0034] (1) 60 parts of needle-shaped nano-aluminum hydroxide, 45 parts of boron oxide, 45 parts of alkylphenyl bisphosphate and 1 part of silane coupling agent KH-550 are mixed uniformly in a high-speed mixer with a speed of 70 rpm, After obtaining the modified flame retardant filler, wherein, the length of the needle-like nano-aluminum hydroxide is 45nm, and the diameter is 6nm;

[0035] (2) Take 4 parts of white oil to carry out oil extension treatment on 100 parts of homopolypropylene with a melt index of 10kg / 10min, and take 4 parts of white oil to carry out oil extension treatment on 100 parts of random copolymer polypropylene with a melt index of 10kg / 10min Process, wherein, white oil is 26# industrial plastic processing oil;

[0036] (3) Extrude the modified flame-retardant filler obtained in step (1) and the homopolypropy...

Embodiment 2~8

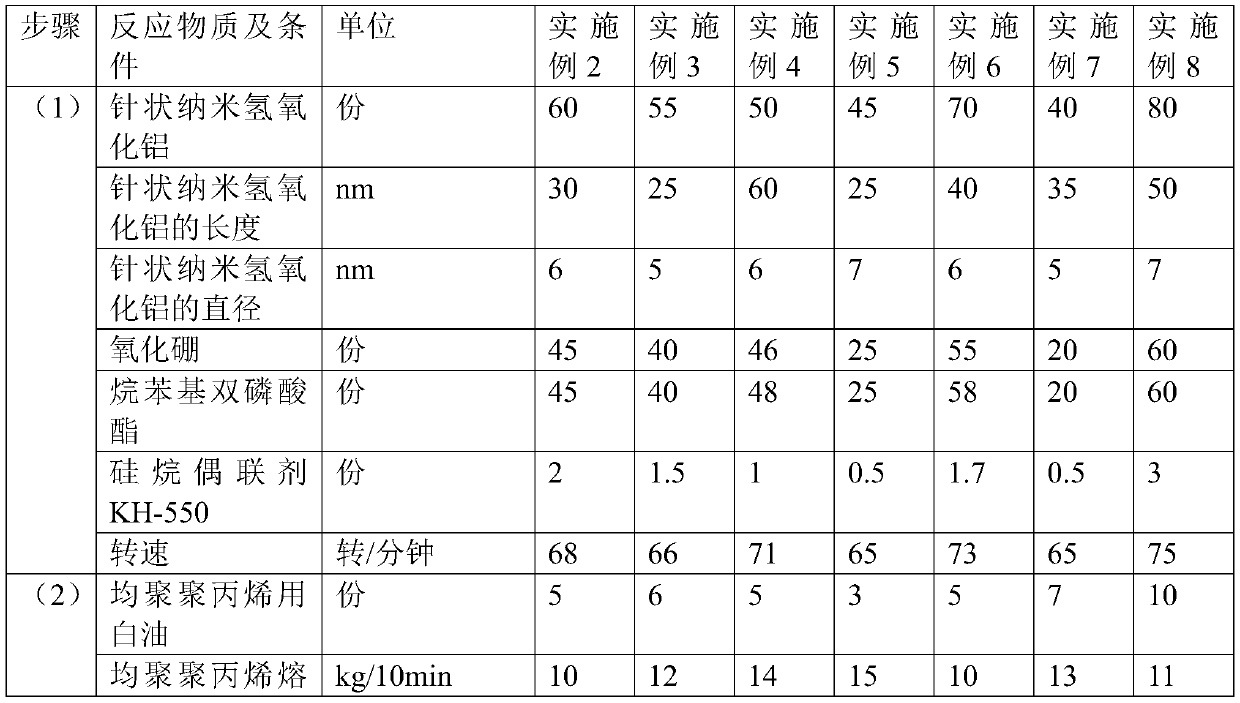

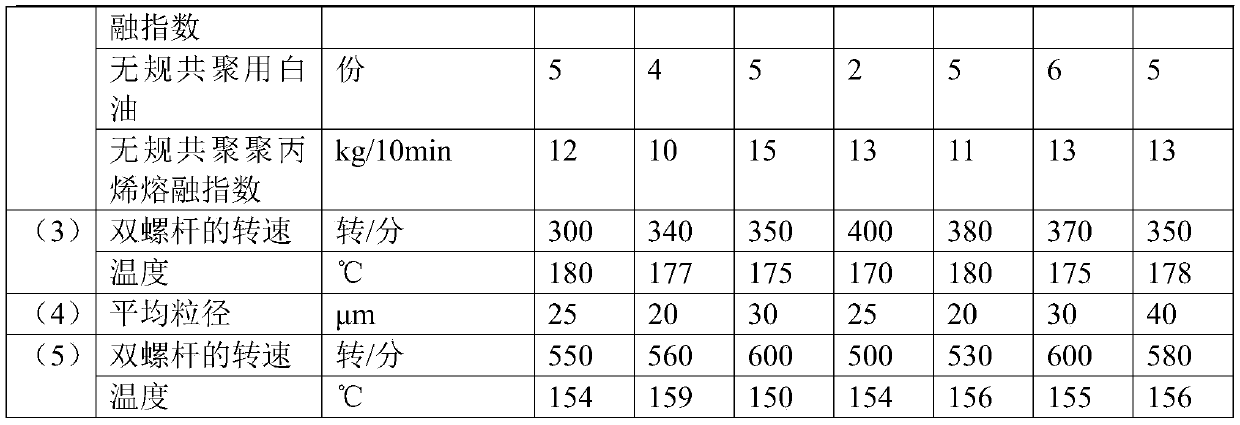

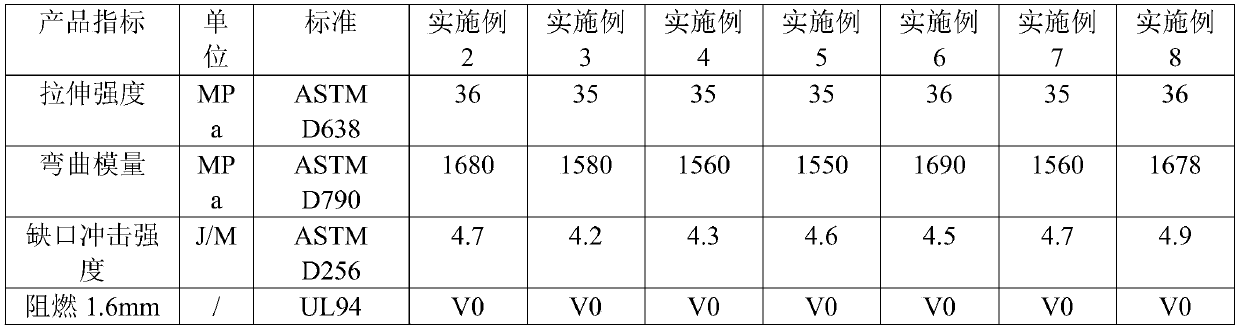

[0043] In Examples 2-8, the preparation method of the high-efficiency halogen-free flame-retardant masterbatch of polypropylene carrier, the specific steps are basically the same as in Example 1, the difference lies in the addition amount of each component and the processing conditions in each step. For the data, see Table 2, 6 parts of the final high-efficiency halogen-free flame-retardant masterbatch of polypropylene carrier and 100 parts of polypropylene (Aramco Asia's HP120G) were blended and plasticized to make a standard sample, and tested. The test results are shown in Table 3 .

[0044] Table 2

[0045]

[0046]

[0047] table 3

[0048]

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com