Phosphorus-containing vegetable oil-based flame-retardant polyol and its preparation method and application

A flame-retardant polyol, vegetable oil-based technology, which is applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc. problem, to achieve good synergistic flame retardant effect, improved storage stability, and high flame retardancy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] See Attached Table 1 and Attached Table 2 for the preparation formula and performance test results of vegetable oil-based flame-retardant rigid polyurethane foam. The combination of polyol and isocyanate is used as the main raw material. When foaming, the molar ratio of NCO / OH is 1.5-2.5. The specific operation is as follows: Mix the combined polyol and additives evenly under the condition of rapid stirring, then stir with 130 parts of isocyanate at the speed of 2000-3000r / min for 10-20s, pour into the mold, and mature for 48h .

[0045] The selection of isocyanate: toluene diisocyanate, xylene diisocyanate, polymethyl polyphenyl polyisocyanate (PAPI), preferably PAPI, the trade name is PM-200 of Yantai Wanhua Polyurethane Co., Ltd.

Embodiment 1

[0047] Proportionally, weigh 4.0g phosphotungstic acid, dissolve in 15mL distilled water, add 31mL 30wt.% H 2 o 2 Stir at room temperature to make it dissolve completely and mix evenly; add 1.30 g of dodecylpyridinium chloride chloroform solution dropwise into the above solution using a dropping funnel, and continue stirring for 30 min at the same time, after the reaction ends , filtered, and vacuum-dried at 60°C to obtain a quaternary ammonium phosphotungstic acid phase transfer catalyst.

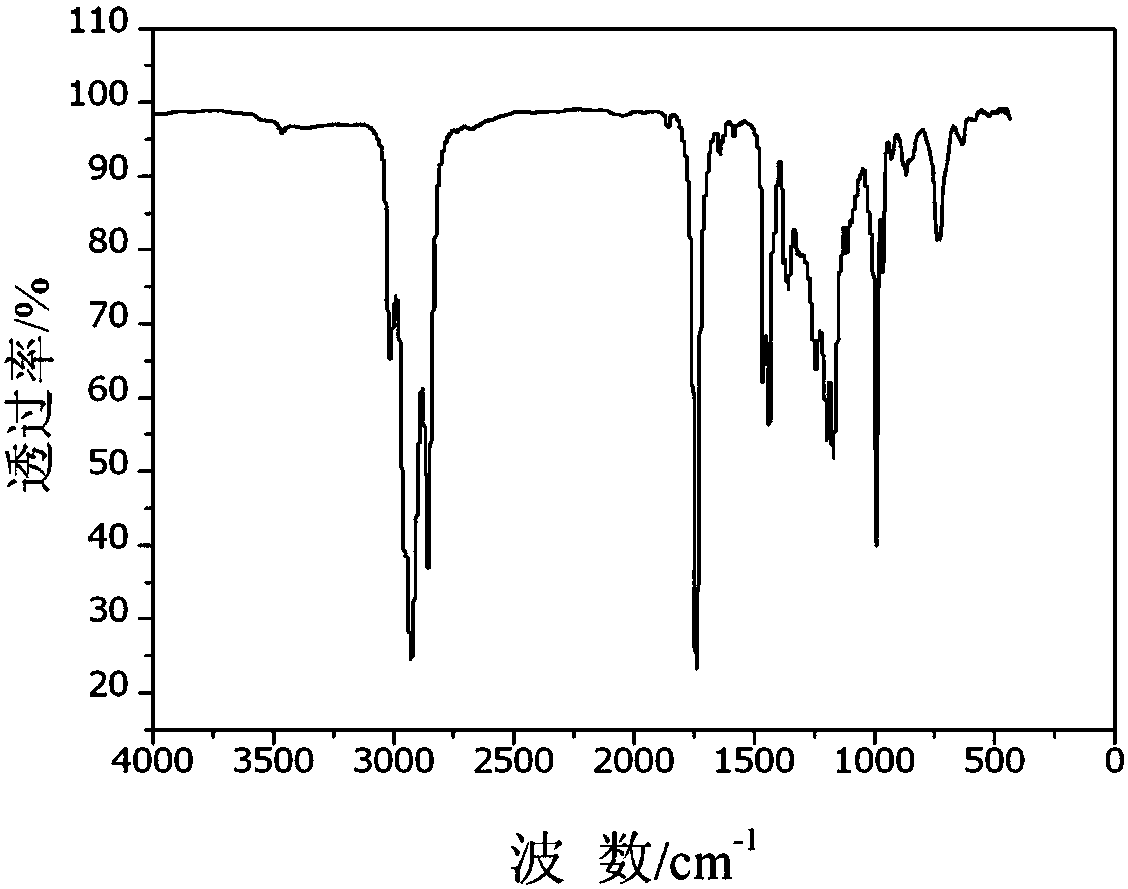

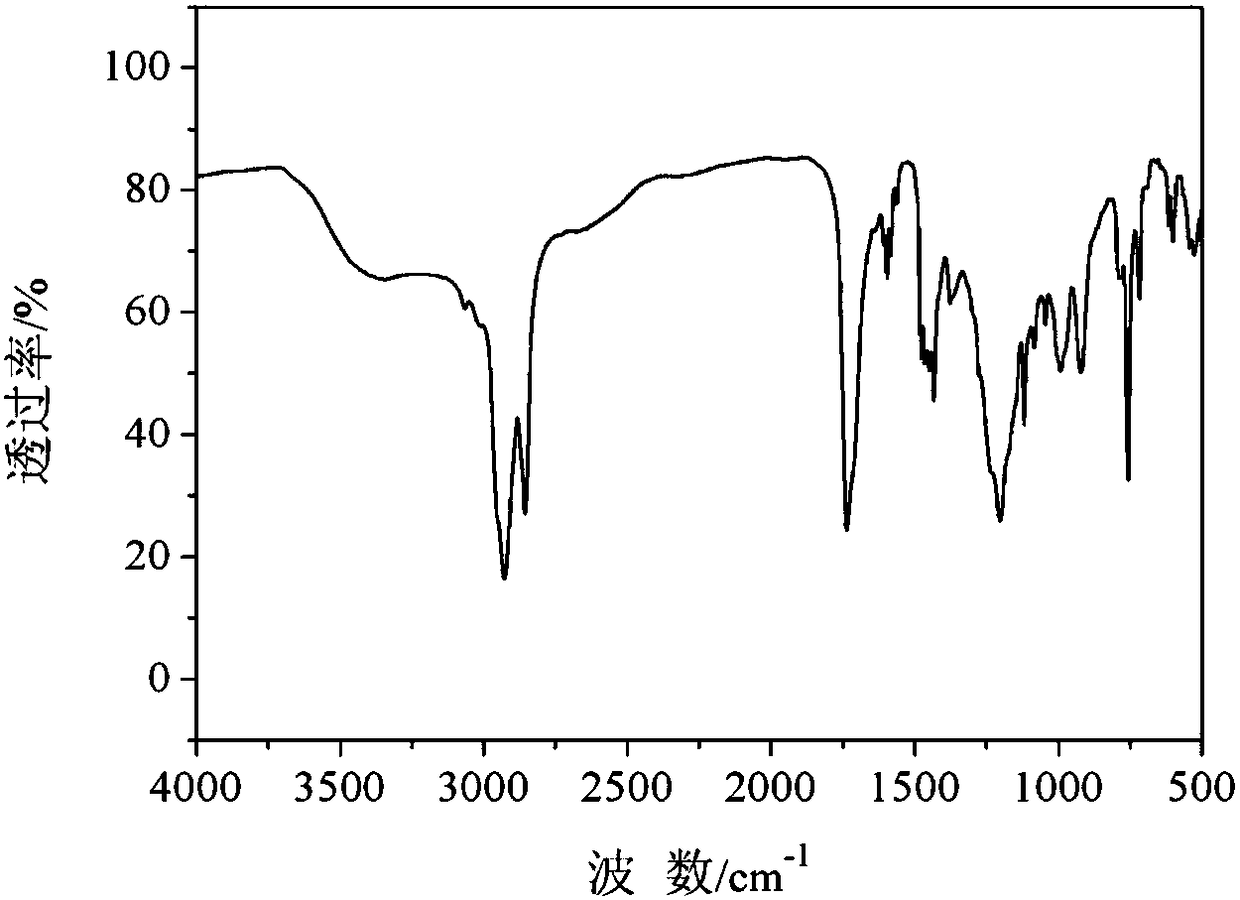

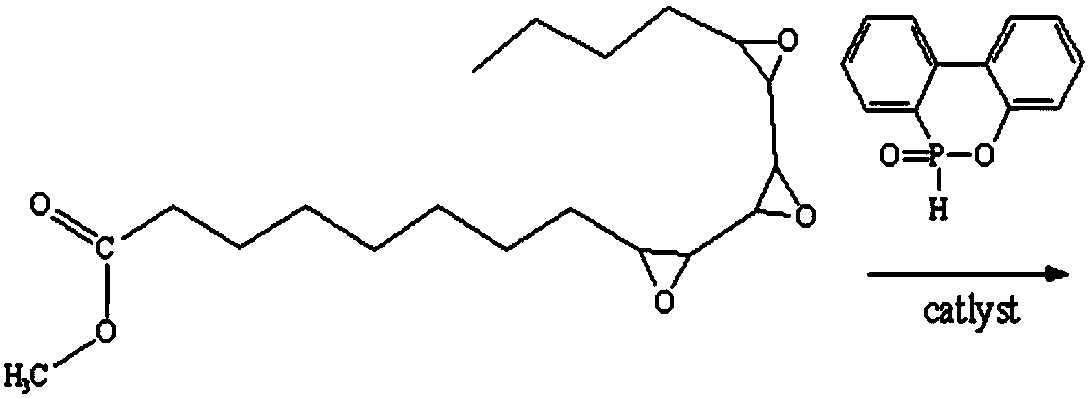

[0048] Tung oil methyl ester and hydrogen peroxide are epoxidized to obtain epoxidized tung oil methyl ester (mol ratio n C=C :n H2O2 =1:2), the epoxidation reaction condition is 50°C, and the reaction time is 4h; after the reaction is completed, it is cooled to -15°C, and the hydrogen peroxide, water and catalyst in the system are separated by centrifugation; 60 parts by mass of epoxy Put tung oil methyl ester and 0.06 parts by mass of triphenylphosphine in a four-necked flask, and aft...

Embodiment 2

[0050] Proportionally, weigh 4.0g phosphotungstic acid, dissolve in 15mL distilled water, add 35mL 30wt.% H 2 o 2 Stir at room temperature to make it dissolve completely and mix evenly; add 1.30 g of dodecylpyridinium chloride chloroform solution dropwise into the above solution using a dropping funnel, and continue stirring for 30 min at the same time, after the reaction ends , filtered, and vacuum-dried at 60°C to obtain a quaternary ammonium phosphotungstic acid phase transfer catalyst.

[0051] Tung oil methyl ester and hydrogen peroxide are epoxidized to obtain epoxidized tung oil methyl ester (mol ratio n C=C :n H2O2 =1:2), the epoxidation reaction condition is 50°C, and the reaction time is 4h; after the reaction is completed, it is cooled to -15°C, and the hydrogen peroxide, water and catalyst in the system are separated by centrifugation; 60 parts by mass of epoxy Put tung oil methyl ester and 0.05 parts by mass of triphenylphosphine in a four-necked flask, and aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com