High-performance flame-retardant SEBS graft polymer and preparation method thereof

A graft polymer, high-performance technology, applied in the field of graft polymer preparation, can solve problems such as performance degradation, achieve the effect of optimizing material performance, improving product quality, and optimizing heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

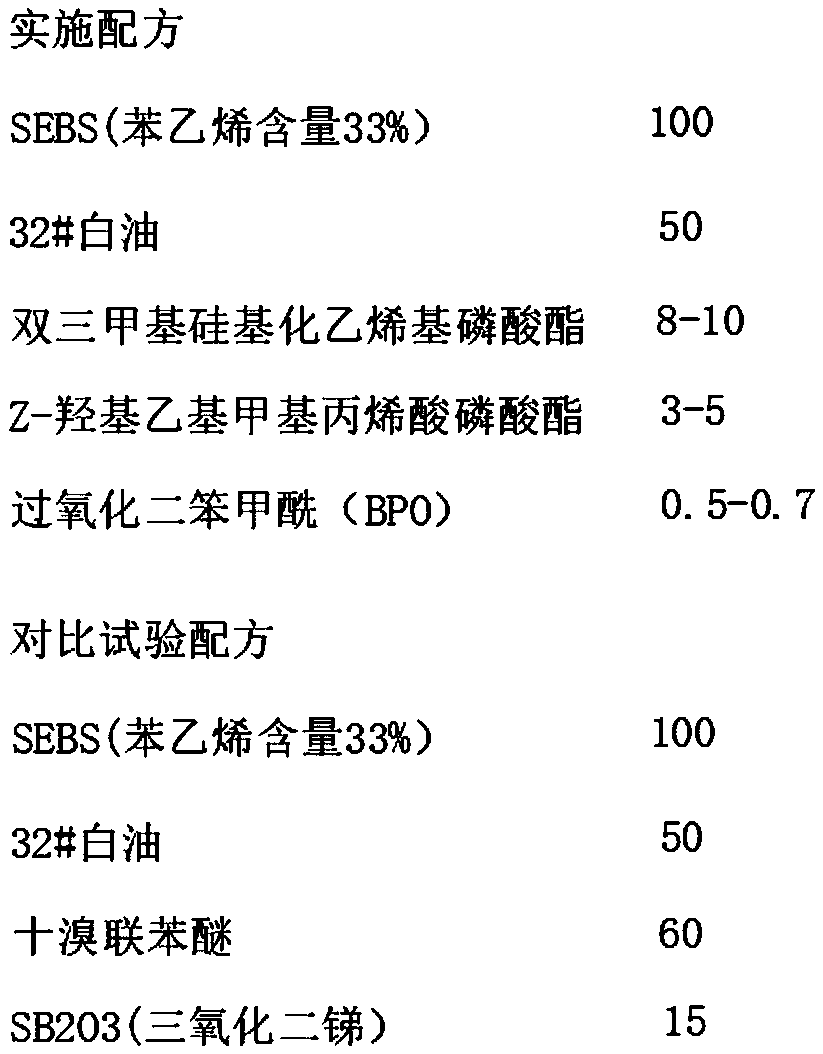

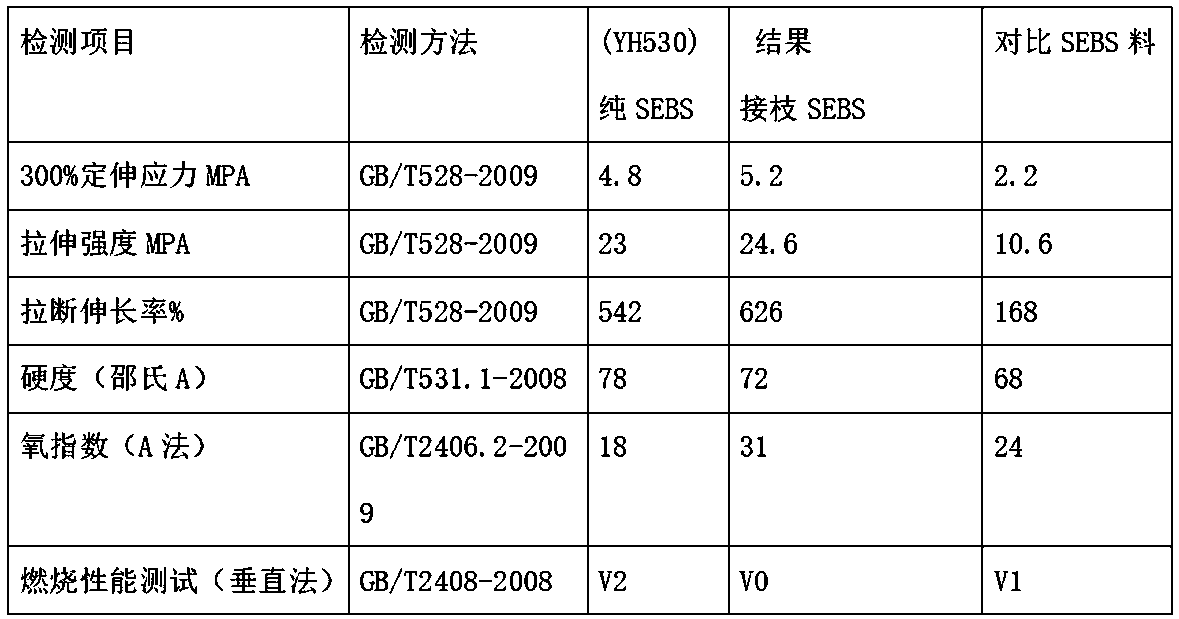

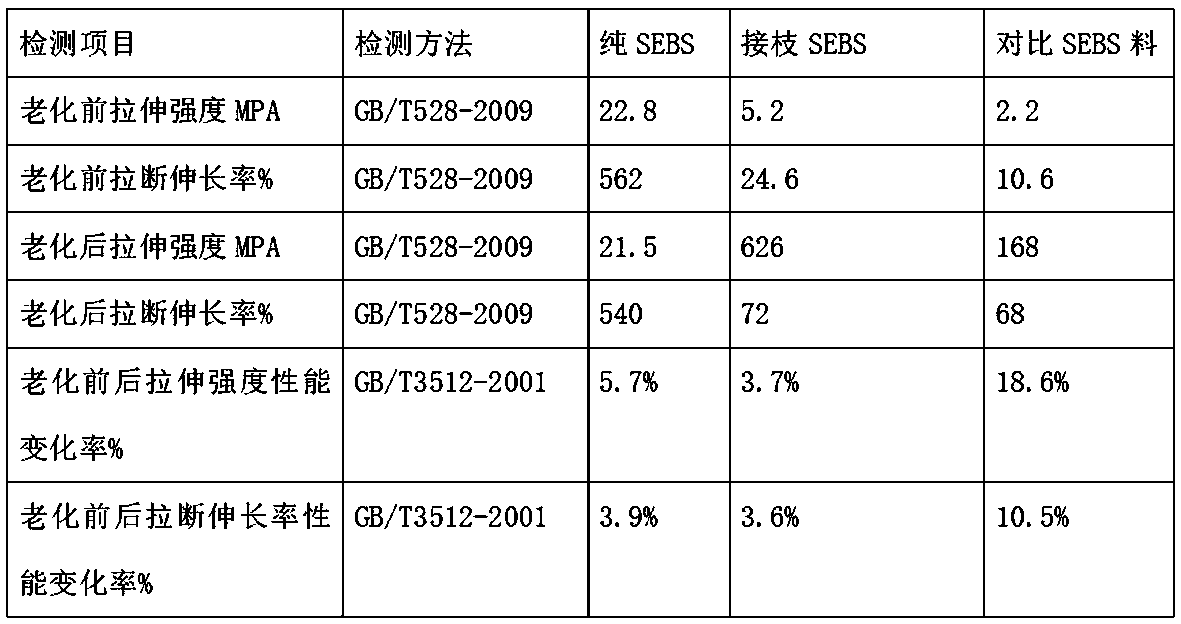

[0044] see figure 1 , a high-performance flame-retardant SEBS graft polymer, including SEBS (YH-503, 33% styrene content), 32# white oil, graft monomers and initiators, graft monomers include bistrimethylsilane Vinyl phosphate and Z-hydroxyethyl methacrylate phosphate, the initiator includes dibenzoyl peroxide (BPO), in parts by mass: SEBS (YH-503, styrene content 33%) 100 50 parts of 32# white oil, 8-10 parts of bistrimethylsilylated vinyl phosphate, 3-5 parts of Z-hydroxyethyl methacrylate phosphate, 0.5 parts of dibenzoyl peroxide (BPO) -0.7 copies.

[0045] A kind of high-performance flame-retardant SEBS graft polymer, its preparation method is:

[0046] S1. Weigh SEBS and 32# white oil according to the formula, then add the weighed SEBS and 32# white oil into a high-speed mixer running at a speed of 60r / min (the high-speed mixer has 60r / min and 120r / min Two rotation speeds), in order to make the oil filling uniform and prevent the filled oil from leaking out, the low s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com