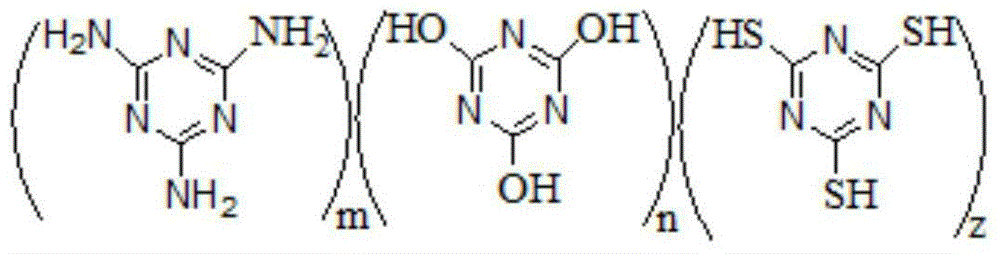

Modified melamine cyanurate fire retardant and preparation method thereof

A technology of melamine cyanurate and melamine, which is applied in the field of flame retardant preparation, can solve the problems of reducing the flame retardant efficiency of MCA, long water removal time, and reducing the viscosity of the reaction system, so as to achieve a good synergistic flame retardant effect and shorten the reaction time. Time, the effect of reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

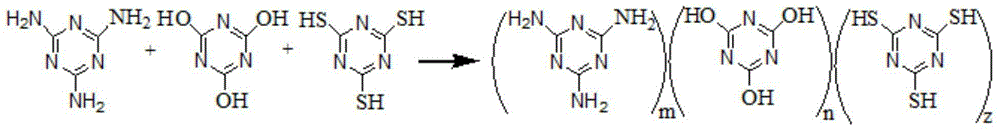

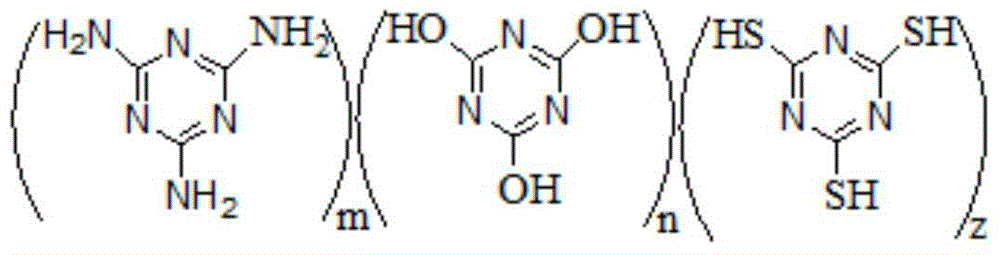

Method used

Image

Examples

Embodiment 1

[0021] In a reaction kettle with a stirrer and a thermometer, add 1 mol of melamine, 0.5 mol of cyanuric acid, 0.5 mol of thiocyanuric acid and 800 ml of water, stir, and keep the temperature at 80°C for 5 hours. The viscous paste of melamine cyanurate modified with thiocyanic acid is obtained, and the product is obtained after filtering, drying and pulverizing.

Embodiment 2

[0023] In a reaction kettle with a stirrer and a thermometer, add 1 mol of melamine, 0.6 mol of cyanuric acid, 0.5 mol of thiocyanuric acid and 400 ml of water, stir, and keep the temperature at 90°C for 4 hours. The viscous paste of melamine cyanurate modified with thiocyanic acid is obtained, and the product is obtained after filtering, drying and pulverizing.

Embodiment 3

[0025] In a reaction kettle with a stirrer and a thermometer, add 1 mol of melamine, 0.6 mol of cyanuric acid, 0.3 mol of thiocyanuric acid and 700ml of water, stir, and keep the temperature at 100°C for 3 hours. The viscous paste of melamine cyanurate modified with thiocyanic acid is obtained, and the product is obtained after filtering, drying and pulverizing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com