ABS flame-retardant composite material prepared by using acrylic artificial stone waste materials and preparation method thereof

A flame-retardant composite material and acrylic technology, which is applied in the field of flame-retardant materials, can solve the problems of affecting the absorption of moisture and nutrients of crops, crop production reduction, and difficult to degrade, etc., so as to achieve easy industrial production implementation and popularization and application, good economy and society Significance, the effect of improving flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

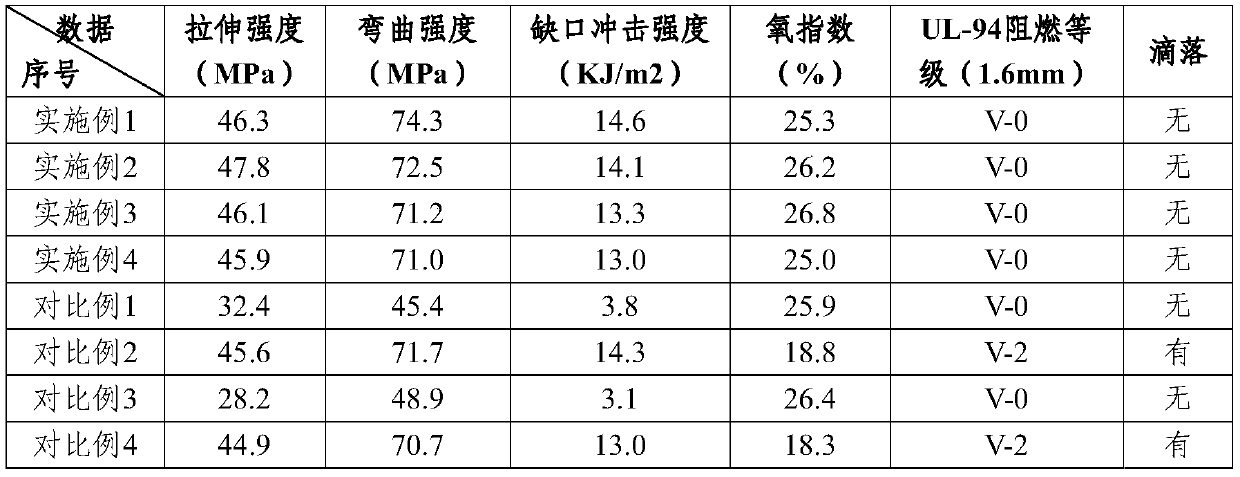

Examples

Embodiment 1

[0030] (1) The preparation of modified acrylic artificial stone waste powder comprises the following steps:

[0031] T1: configuration of titanate coupling agent solution, prepare titanate coupling agent solution with titanate coupling agent and absolute ethanol according to the mass ratio of 1:5;

[0032] T2: Preparation of acrylic artificial stone waste powder. Add acrylic artificial stone waste to a ball mill for grinding and refinement. After grinding, sieve through a 200-mesh standard sieve to obtain acrylic artificial stone waste powder. The speed of the ball mill is 400r / min~500r / min min, the grinding time is 1h~1.5h;

[0033] T3: Preparation of acrylic artificial stone waste powder dispersion. Place the acrylic artificial stone waste powder in step T2 in a dispersion container filled with deionized water, and ultrasonically vibrate for 1 hour to obtain acrylic artificial stone waste powder dispersion. The mass ratio of stone waste powder to deionized water is 1:20;

...

Embodiment 2

[0040] The difference between Example 2 and Example 1 is that (1) the preparation of modified acrylic artificial stone waste powder, the mass ratio of titanate coupling agent solution to acrylic artificial stone waste powder in step T4 is 1:100; (two ) Using acrylic artificial stone waste powder to prepare ABS flame-retardant composite materials, step S2 raw materials are pre-mixed, 100 parts of dry ABS resin, 30 parts of modified acrylic artificial stone waste powder, 3 parts of compatibilizer SMA-800, compatibilizer ABS -2 parts of g-MAH, 15 parts of flame retardant bisphenol A bis(diphenyl phosphate), 0.8 parts of lubricant zinc stearate and 0.7 parts of antioxidant 618 were added to the high-speed mixer in sequence, and stirred and mixed for 10 minutes. A mixture of raw materials was obtained.

Embodiment 3

[0042] The difference between Example 3 and Example 1 is that (1) the preparation of modified acrylic artificial stone waste powder, the mass ratio of titanate coupling agent solution to acrylic artificial stone waste powder in step T4 is 1:150; (two) ) Using acrylic artificial stone waste powder to prepare ABS flame-retardant composite materials, step S2 raw materials are pre-mixed, 100 parts of dry ABS resin, 40 parts of modified acrylic artificial stone waste powder, 4 parts of compatibilizer SMA-700, compatibilizer ABS -5 parts of g-MAH, 20 parts of flame retardant triphenyl phosphate, 0.5 parts of lubricant ethylene bis stearic acid amide, 0.5 parts of lubricant silicone powder, 0.5 parts of antioxidant 168 and 0.3 parts of antioxidant 1076 Sequentially add to a high-speed mixer, stir and mix for 20 minutes to obtain a raw material mixture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com