Synergic flame retardance asphalt material and preparation method thereof

A kind of asphalt material and synergistic flame retardant technology, which is applied in building insulation materials, building components, buildings, etc., can solve the problems of high flame retardant effect of additives, and achieve the effect of excellent road performance, improved application performance, and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

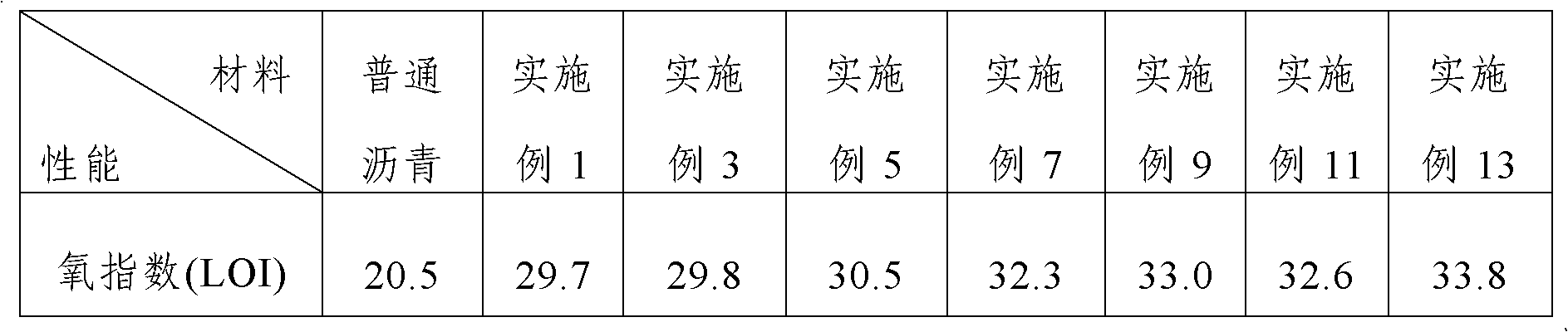

Examples

Embodiment 1

[0020] The synergistic flame-retardant asphalt material of this embodiment is made by mixing the following raw materials: 100kg of asphalt, 40kg of metal hydroxide, and 0.1kg of layered silicate; the asphalt is petroleum asphalt, and the metal hydroxide is hydroxide aluminum, and the layered silicate is natural sepiolite.

[0021] The preparation method of the synergistic flame-retardant asphalt material in this example is: heat the asphalt to 150°C and place it in a high-speed shearer, and stir the asphalt at a speed of 1000 rpm; then, under the same temperature and stirring conditions, , add the metal hydroxide with a particle size of not more than 200 mesh into the high-speed shearer equipped with asphalt at a constant speed within 3 minutes, continue to stir for 10 minutes, and after cooling at room temperature, a synergistic flame-retardant asphalt material is obtained.

[0022] The flame-retardant asphalt material of this embodiment has excellent road performance and mee...

Embodiment 2

[0024] This embodiment is the same as Example 1, wherein the difference is that the pitch is rock pitch or coal pitch, or two or three of petroleum pitch, rock pitch and coal pitch; the metal hydroxide is Magnesium hydroxide or magnesium hydroxide and aluminum hydroxide; The layered silicate is natural rectorite, natural montmorillonite or natural kaolin minerals, or natural montmorillonite, natural rectorite, natural sepiolite and At least two of the naturally occurring kaolin minerals.

[0025] The preparation method of the synergistic flame retardant asphalt material of this example is the same as that of Example 1.

[0026] The flame-retardant asphalt material of this embodiment has excellent road performance and meets the requirements of use, and the storage stability can reach more than one year, and the temperature sensitivity and aging resistance are obviously higher than ordinary asphalt.

Embodiment 3

[0028] The synergistic flame-retardant asphalt material of this embodiment is made by mixing the following raw materials in parts by weight: 100 kg of asphalt, 0.2 kg of metal hydroxide, and 30 kg of layered silicate; the asphalt is rock asphalt, and the metal hydroxide is magnesium hydroxide, and the layered silicate is natural montmorillonite.

[0029] The preparation method of the synergistic flame-retardant asphalt material in this embodiment is: heat the asphalt to 120°C and place it in a high-speed shearer, and stir the asphalt at a speed of 6000rpm; then, under the same temperature and stirring conditions, , add the metal hydroxide with a particle size of not more than 200 mesh into the high-speed shearer equipped with asphalt at a constant speed within 1 minute, and continue to stir for 30 minutes; finally, under the same temperature and stirring conditions, layer the The silicate was added into the high-speed shearer at a constant speed within 3 minutes, continued to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com