Highly weather-resistant permanent antistatic flame-retardant polypropylene material as well as preparation method and application thereof

A flame-retardant polypropylene and antistatic technology, applied in the field of modification of polymer composite materials, can solve the problems of poor low temperature resistance, difficult processing, poor weather resistance, etc., achieve narrow molecular weight distribution, balance physical and mechanical properties, and improve dust pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

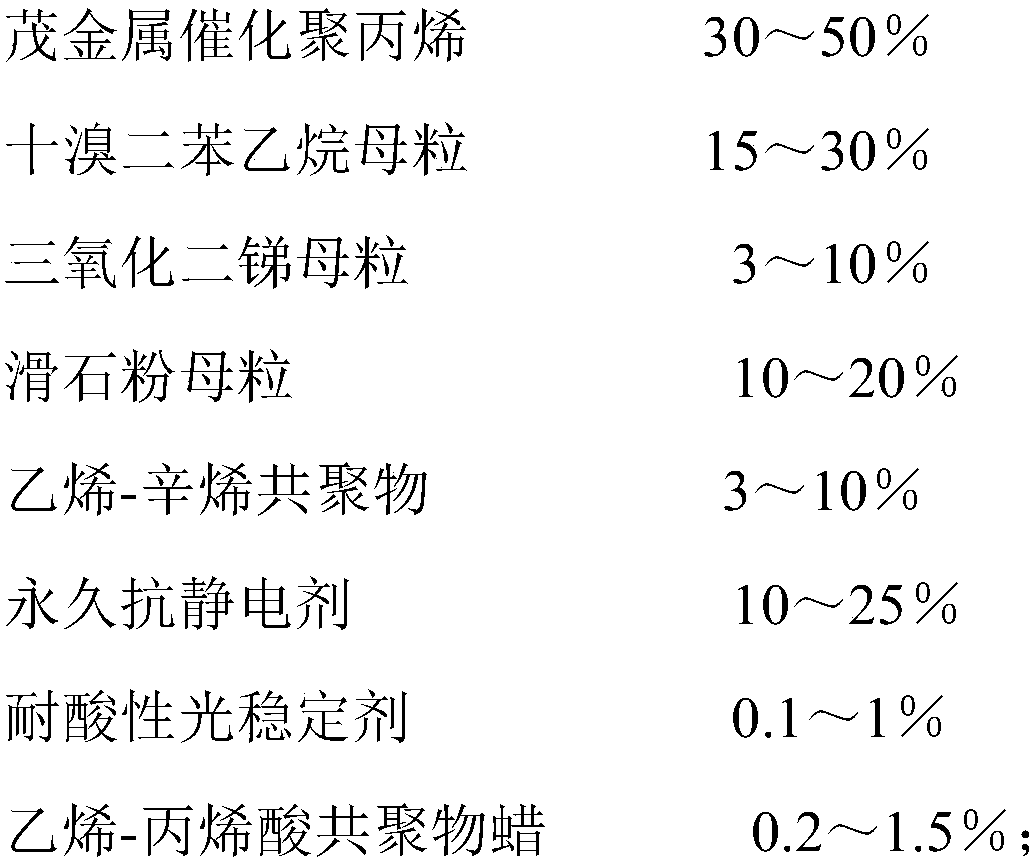

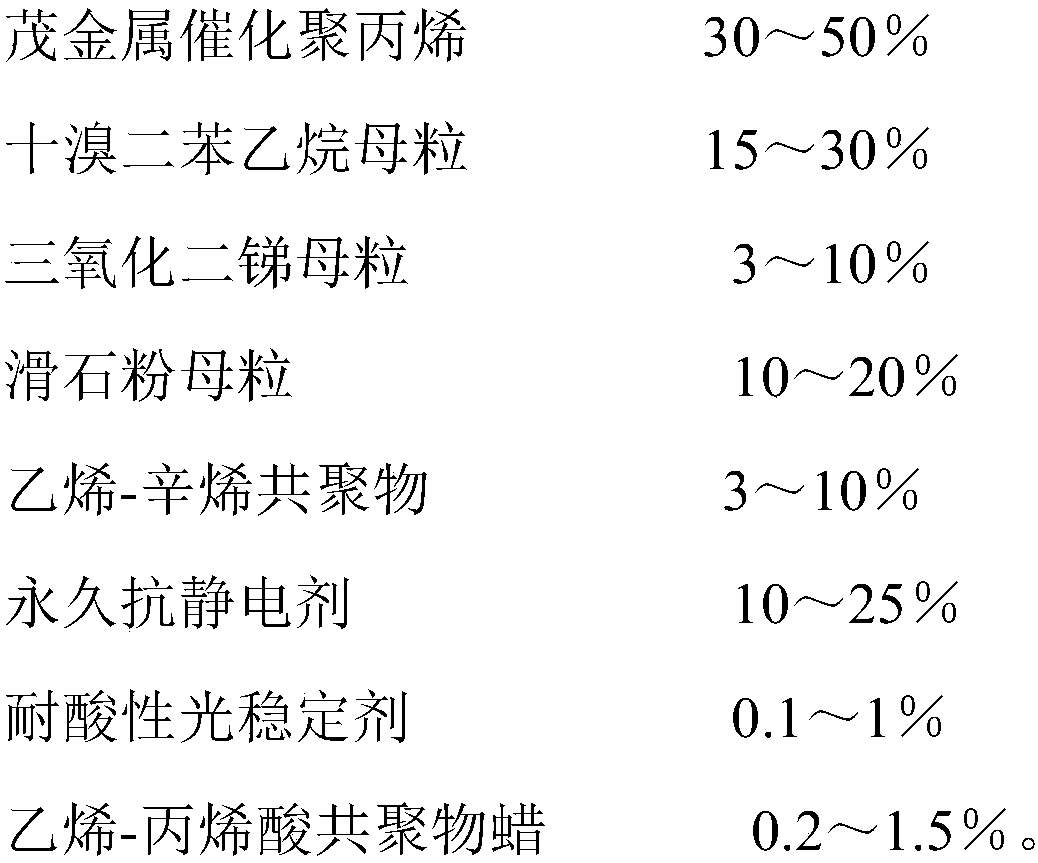

[0034] (1) According to the following mass percentage composition ratio:

[0035] Metallocene catalyzed polypropylene 30% (brand: WMG03, Mitsubishi Chemical Corporation), decabromodiphenylethane masterbatch 30% (brand: FE-03, Jiangsu Wannap New Material Co., Ltd.), antimony trioxide mother 10% (brand: FA-03, Jiangsu Wannap New Material Co., Ltd.), talc masterbatch 15% (brand: BHTM-H1080, Liaoning Beihai Group), 3% ethylene-octene copolymer (brand: DF7350) , Mitsui Chemicals Co., Japan), permanent antistatic agent 10% (brand: PELESTAT 300, Sanyo Chemical Co., Ltd.), acid-resistant light stabilizer 1% (brand: LA-29, 0.5%; brand: QL-914, 0.5% , Are produced by Japan Adike Co., Ltd.), ethylene-acrylic acid copolymer wax 1% (brand: AC 540A, American Honeywell).

[0036] (2) After weighing the above materials, add them to a high-speed mixer (rotating speed 1000rpm) and stir for 3 minutes. Add the uniformly stirred materials to the main feed hopper of the parallel twin-screw extruder wi...

Embodiment 2

[0039] (1) According to the following mass percentage composition ratio:

[0040] Metallocene catalyzed polypropylene 35% (brand: WMG03, Mitsubishi Chemical Corporation), decabromodiphenylethane masterbatch 20% (brand: FE-03, Jiangsu Wannap New Material Co., Ltd.), antimony trioxide mother Grain 8% (brand: FA-03, Jiangsu Wannap New Material Co., Ltd.), talc masterbatch 20% (brand: BHTM-H1080, Liaoning Beihai Group), ethylene-octene copolymer 6% (brand: DF7350) , Mitsui Chemicals Co., Ltd., permanent antistatic agent 10% (brand: PELESTAT 300, Sanyo Chemical Co., Ltd.), acid-resistant light stabilizer 0.5% (brand: LA-29, 0.3%; brand: QL-914, 0.2% , All are produced by Japan Adike Co., Ltd.), ethylene-acrylic acid copolymer wax 0.5% (brand: AC 540A, Honeywell, USA).

[0041] (2) After weighing the above materials, add them to a high-speed mixer (rotating speed 1200rpm) and stir for 3 minutes. Add the uniformly stirred materials to the main feed hopper of the parallel twin-screw extr...

Embodiment 3

[0044] (1) According to the following mass percentage composition ratio:

[0045] Metallocene catalyzed polypropylene 40% (brand: WMG03, Japan Mitsubishi Chemical Corporation), decabromodiphenylethane masterbatch 15% (brand: FE-03, Jiangsu Wannap New Material Co., Ltd.), antimony trioxide mother 4% (brand: FA-03, Jiangsu Wannap New Material Co., Ltd.), talc masterbatch 10% (brand: BHTM-H1080, Liaoning Beihai Group), ethylene-octene copolymer 5% (brand: DF8200) , Mitsui Chemicals Co., Japan), permanent antistatic agent 25% (brand: PELESTAT 300, Sanyo Chemical Co., Ltd.), acid-resistant light stabilizer 0.5% (brand: LA-29, 0.3%; brand: QL-914, 0.2% , All are produced by Japan Adike Co., Ltd.), ethylene-acrylic acid copolymer wax 0.5% (brand: AC 540A, Honeywell, USA).

[0046] (2) After weighing the above-mentioned materials, add them to a high-speed mixer (rotating speed 2000 rpm) and stir for 4 minutes. Add the uniformly stirred materials to the main feed hopper of the parallel tw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com