Preparation method for organic silicon and graphene oxide synergistic flame retardant polymer composite material

A technology of polymer materials and composite materials, applied in the field of preparation of graphene oxide and organosilicon synergistic flame retardant polymer composite materials, can solve the problems of easy combustion, poor fire safety, easy aging, etc., and achieve excellent synergistic flame retardant, Excellent physical properties, excellent flame retardant efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] First wash and dry 0.50g of polyurethane open-cell foam with ethanol; then soak it in a graphene oxide aqueous solution with a concentration of 10mg / mL for 30s, take it out and dry it (60°C) for 10h; after that, take formazan with a solid content of 80%. Base silicone resin solution 40g, and add toluene 61.3g to dilute to solid content 30%, then catalyst polyether amine (D230) 0.8g mixes evenly; Then immerse the dried graphene oxide-coated polyurethane foam composite material into the above-mentioned organic Silicone resin solution, fully dipped. Finally, the spin-coated silicone resin composite foam material was rotated to remove excess solution, and put into an oven at 80° C. for curing for 2 hours. After cooling, the solidified graphene oxide and silicone resin synergistically flame-retardant polyurethane foam composite material 1 is obtained.

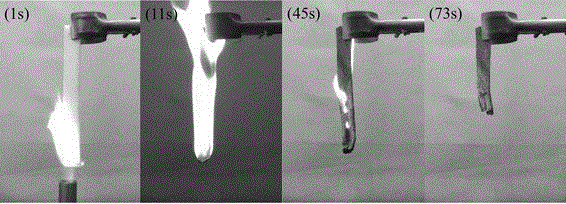

[0024] Ignition tests show that: compared to pure silicone modified polyurethane foam (such as figure 1 ), under the same...

Embodiment 2

[0026] First clean the surface of 10g of cured epoxy resin block, then soak it in the graphene oxide aqueous solution with a concentration of 1mg / mL for 600s, take it out and dry it (100°C) for 2h; after that, take methylbenzene with a solid content of 20%. Base silicone resin solution 40g, catalyst benzoic anhydride 0.2g and mix evenly; then immerse the dried graphene oxide-coated epoxy resin composite material in the above-mentioned silicone resin solution, and fully dip-coat. Finally, it was put into an oven for curing at 80° C. for 10 h. After cooling, the cured graphene oxide and silicone resin synergistically flame-retardant epoxy resin-based composite material 2 is obtained.

[0027] The ignition test shows that compared with the pure silicone modified epoxy resin, under the same silicone resin content, the graphene oxide and organic silicon synergistic flame retardant epoxy resin composite material can hardly be ignited, and there is no molten droplet dripping , and m...

Embodiment 3

[0029] Firstly clean the surface of 0.50g polystyrene foam, then soak it in the graphene oxide aqueous solution with a concentration of 6mg / mL for 60s, take it out and dry it (80°C) for 4h; Add 0.35 g of catalyst benzoic acid to 40 g of silicone resin solution and mix evenly; then immerse the dried graphene oxide-coated polystyrene foam composite material in the above-mentioned silicone resin solution for full dip coating. Finally, the spin-coated silicone resin composite foam material was rotated to remove excess solution, and put into an oven at 80° C. for curing for 2 hours. After cooling, the solidified graphene oxide and silicone resin synergistically flame-retardant polystyrene foam composite material 3 is obtained.

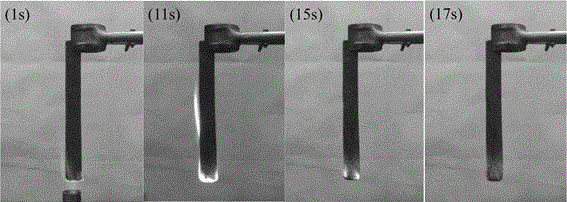

[0030] The ignition test shows that compared with pure polystyrene foam, under the same silicone resin content, the graphene oxide and silicone synergistic flame-retardant polystyrene foam composite material is self-extinguishing in 25s, has self-extinguish...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com