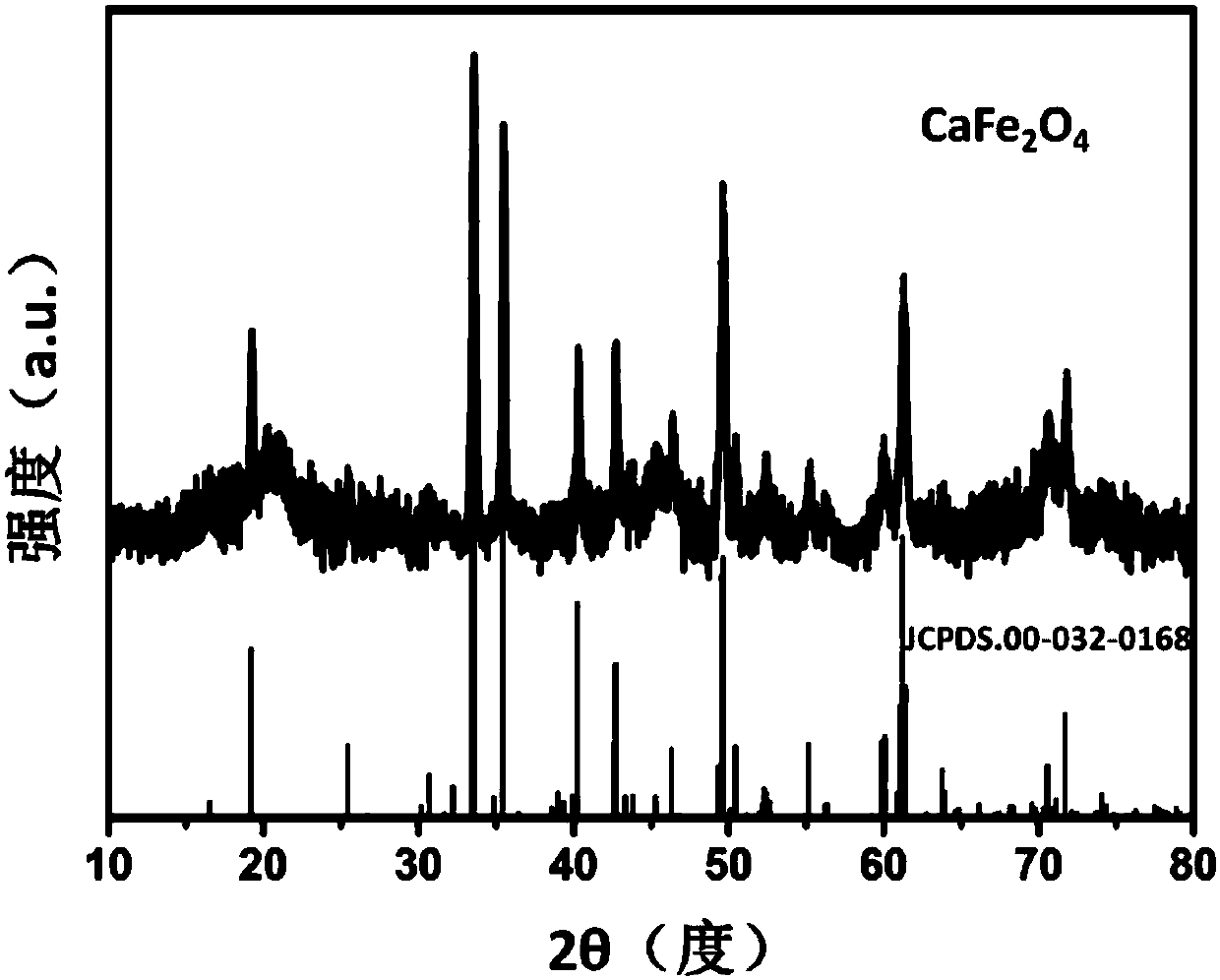

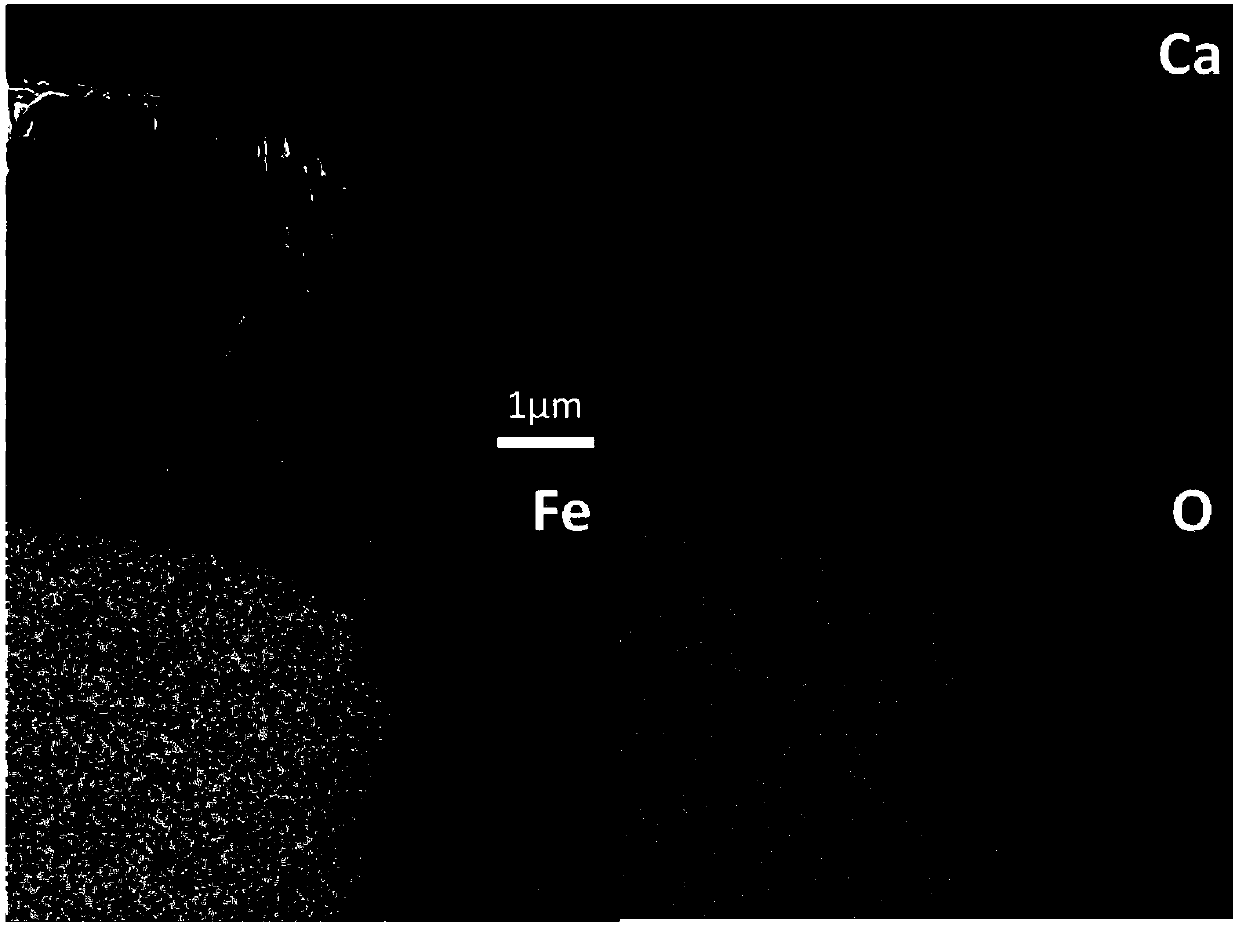

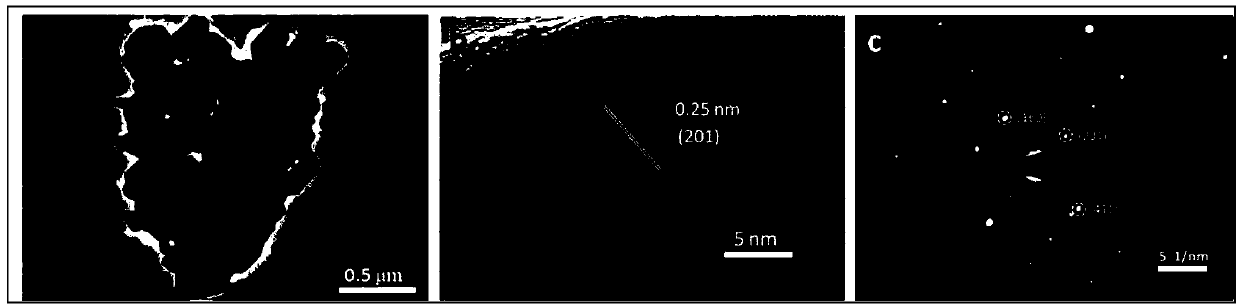

Alkaline earth metal ferrite electrode material and preparation method and application thereof

A technology of alkaline earth metals and ferrites, applied in the field of nanomaterials and electrochemistry, to achieve good cycle stability, high tap density, and excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation of alkaline earth metal ferrite electrode material includes the following steps:

[0032] 1) Weigh 2.0g PVP and add it to 25ml DMF, and stir with a magnetic stirrer for 60 minutes;

[0033] 2) Weigh 4.0mmol Ca(NO 3 ) 2 (or Mg(NO 3 ) 2 ) and 8.0mmol Fe(NO 3 ) 3 ;

[0034] 3) Add the medicine obtained in step 2) to the solution obtained in step 1), and stir with a magnetic stirrer for 3 hours;

[0035] 4) Transfer the solution obtained in step 3) to an oven at 80 degrees centigrade to dry for 24 hours, and after naturally cooling to room temperature, take out a red glassy product;

[0036] 5) heat-treat the dried product obtained in step 4) at 250°C for 1 hour in an air atmosphere with a heating rate of 2°C / min, then heat-treat at 800°C for 5 hours in an air atmosphere at a heating rate of 5°C / min, and let it The sample is cooled naturally, and the calcium ferrite (or magnesium ferrite) sample is obtained immediately after taking it out.

[0037] ...

Embodiment 2

[0046] The preparation of alkaline earth metal ferrite electrode material includes the following steps:

[0047] 1) Weigh 4.0g PVP and add it to 50ml DMF, stir with a magnetic stirrer for 60 minutes;

[0048] 2) Weigh 8.0mmol Ca(NO 3 ) 2 (or Mg(NO 3 ) 2 ) and 16.0mmol Fe(NO 3 ) 3 ;

[0049] 3) Add the medicine obtained in step 2) to the solution obtained in step 1), and stir with a magnetic stirrer for 3 hours;

[0050] 4) Transfer the solution obtained in step 3) to an oven at 80 degrees centigrade to dry for 24 hours, and after naturally cooling to room temperature, take out a red glassy product;

[0051] 5) heat-treat the dried product obtained in step 4) at 250°C for 1 hour in an air atmosphere with a heating rate of 2°C / min, then heat-treat at 800°C for 5 hours in an air atmosphere at a heating rate of 5°C / min, and let it The sample is cooled naturally, and the calcium ferrite (or magnesium ferrite) sample is obtained immediately after taking it out.

[0052] In ...

Embodiment 3

[0054] The preparation of alkaline earth metal ferrite electrode material includes the following steps:

[0055] 1) Weigh 2.0g PVP and add it to 25ml DMF, and stir with a magnetic stirrer for 60 minutes;

[0056] 2) Weigh 4.0mmol Ca(NO 3 ) 2 (or Mg(NO 3 ) 2 ) and 8.0mmol Fe(NO 3 ) 3 ;

[0057] 3) Add the medicine obtained in step 2) to the solution obtained in step 1), and stir with a magnetic stirrer for 3 hours;

[0058] 4) Transfer the solution obtained in step 3) to an oven at 80 degrees centigrade to dry for 24 hours, and after naturally cooling to room temperature, take out a red glassy product;

[0059] 5) heat-treat the dried product obtained in step 4) at 250°C for 1 hour in an air atmosphere at a heating rate of 2°C / min, then heat-treat at 600°C in an air atmosphere for 5 hours at a heating rate of 5°C / min, and let it The sample is cooled naturally, and the calcium ferrite (or magnesium ferrite) sample is obtained immediately after taking it out.

[0060] Fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com