Method for preparing coated layered positive electrode material from sodium metaaluminate

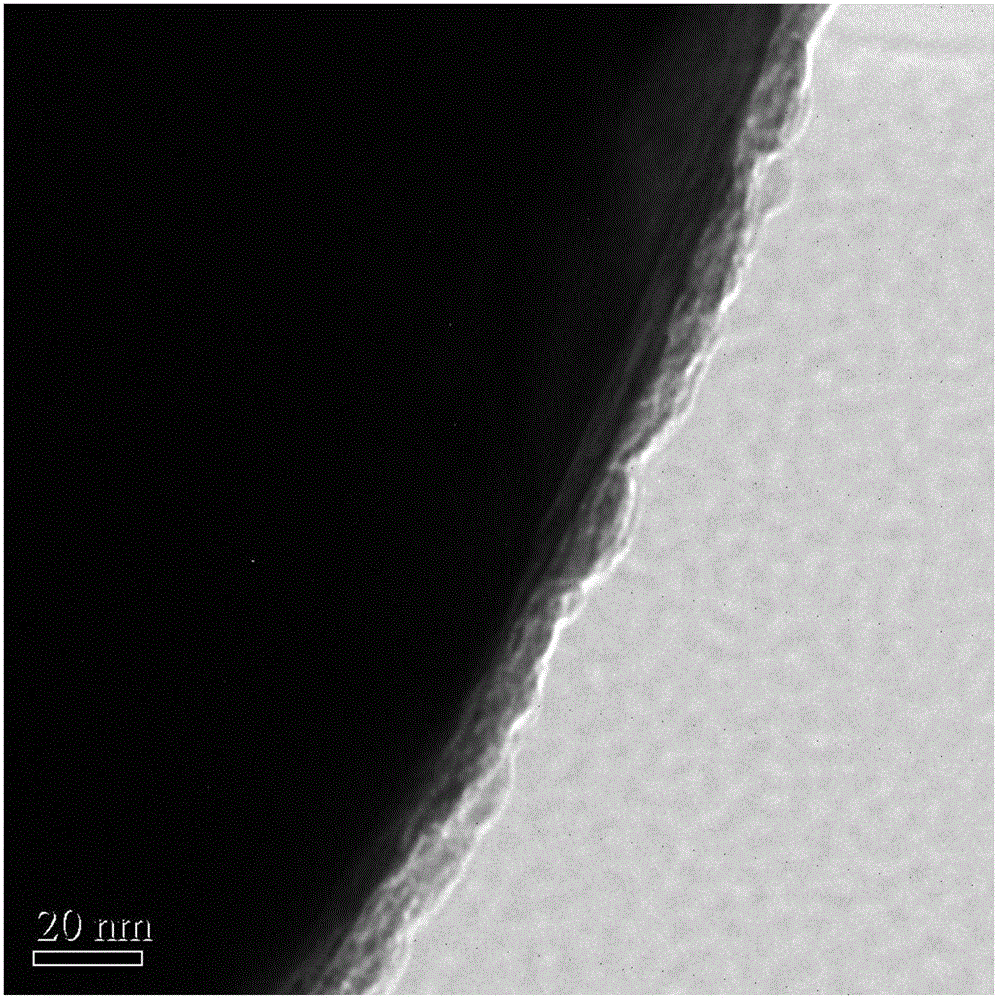

A technology of using sodium metaaluminate and positive electrode materials, which is applied in the field of preparation of layered positive electrode materials coated with sodium metaaluminate as a raw material, can solve the problems of incomplete coating layer and the inability to further improve the electrochemical performance of LiCoO2, and achieve technological Easy control, excellent cycle performance, improved integrity and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

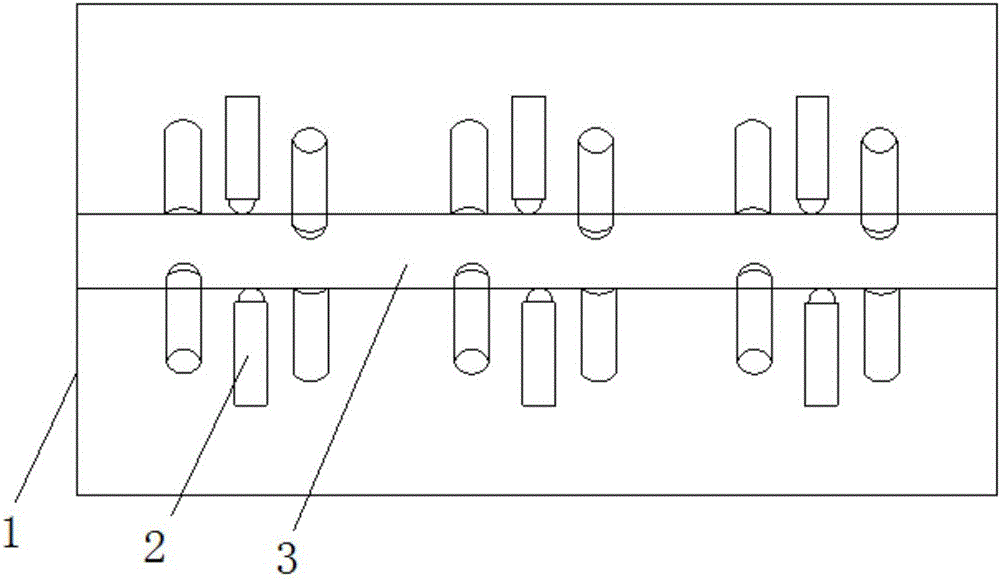

[0034] A kind of preparation method that uses sodium metaaluminate as raw material coating layered cathode material, comprises the following steps:

[0035] Step 1: Weigh polyvinylpyrrolidone (PVP) and the layered positive electrode material at a mass ratio of 1:75, first dissolve the polyvinylpyrrolidone in deionized water, then disperse the layered positive electrode material in it, and configure solution A;

[0036] Step 2: Weigh the complexing agent and sodium metaaluminate according to the amount ratio of substances of 5:100 to 30:100;

[0037] Step 3: Dissolve the weighed sodium metaaluminate in deionized water, and prepare 0.01-0.09 mol / L sodium metaaluminate solution B;

[0038] Step 4: Dissolve the weighed complexing agent in an acid solution with a concentration of 0.01mol / L, and configure solution C;

[0039] Step 5: Under vigorous stirring in a constant temperature water bath, use a peristaltic pump to simultaneously pump solutions B and C into solution A at a cer...

Embodiment 2

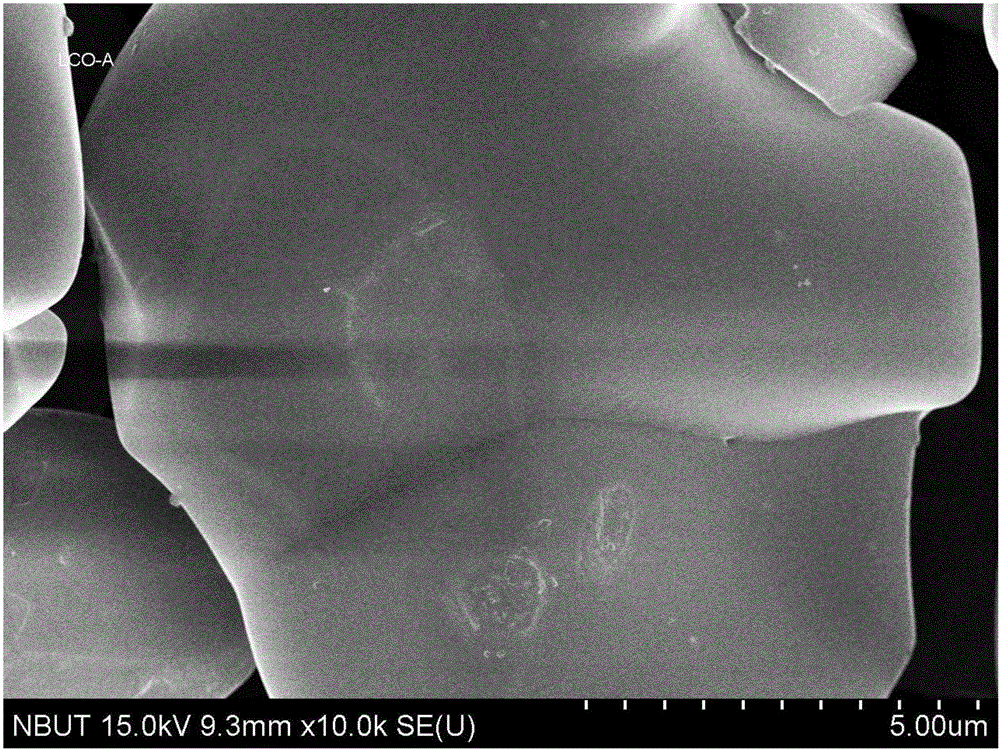

[0050] Example 2: Weigh 0.4g of PVP and dissolve it in 200mL deionized water, then disperse 29.7g of LiCoO2 in it to configure solution A; weigh 0.088g of triethanolamine and 0.483g of NaAlO2 and dissolve it in 100mL of deionized water to configure Solution B; configure 100mL, 0.1mol / L acetic acid solution C; under vigorous stirring in a constant temperature water bath at 50°C, use a peristaltic pump to simultaneously pump solutions B and C into solution A at a certain speed, and control the amount of solution C pumped into The speed stabilizes the reaction pH at around 9; after the solution B is pumped in, stop all peristaltic pumps and continue to stir vigorously in a constant temperature water bath at 50°C for 1 hour; after the reaction is completed, filter and wash the product several times with deionized water and absolute ethanol, Vacuum or dry at 120°C for 12 hours, and finally put the dried product into a muffle furnace, and calcinate at 600°C for 4 hours (the heating r...

Embodiment 3

[0051] Example 3: Weigh 0.4g of PVP and dissolve it in 200mL of deionized water, then disperse 29.7g of LiNi0.8Co0.15Al0.05O2 in it to configure solution A; weigh 0.483g of NaAlO2 and dissolve it in 100mL of deionized water to configure Solution B; Weigh 0.15g of sulfosalicylic acid and dissolve it in 100mL, 0.1mol / L acetic acid to prepare solution C; under vigorous stirring in a constant temperature water bath at 50°C, use a peristaltic pump to mix solutions B and C at a certain speed At the same time, pump into solution A, and stabilize the pH of the reaction at about 10 by controlling the pumping speed of solution C; after the pumping of solution B is completed, stop all peristaltic pumps and continue to stir vigorously in a constant temperature water bath at 50°C for 1 hour; after the reaction, filter The product was washed several times with deionized water and absolute ethanol, vacuum-dried at 120°C for 12 hours, and finally the dried product was put into a muffle furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com