Preparation method of fire retardant polymer polyether polyol and method for preparing block fire retardant polyurethane foam mateial therefrom

A technology of polyether polyol and flame-retardant polymer, which is applied in the field of flame-retardant polymer polyether polyol and its use in the preparation of block flame-retardant polyurethane foam materials, and can solve the problem of high price, thermal instability, and foaming equipment Corrosiveness and other issues, to achieve the effect of low cost, easy foaming, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Example 1: At 40°C, 960 kilograms of polyether polyol N330, 17.4 kilograms of methyl ethyl ketoxime, 34.8 kilograms of toluene diisocyanate and triethylamine, 0.12 kilograms were added to a closed reactor with a stirrer and a thermometer, The temperature was raised to 80°C, and after constant temperature reaction at this temperature for 5 hours, 12 kg of ethylenediamine was added, and then the temperature was raised to 118°C, and reacted for 1 hour. Partially aminated diisocyanate modified polyether polyol I was obtained.

Embodiment 2

[0081] Embodiment 2: 6000, 600 kilograms of polyether polyols, 8.7 kilograms of methyl ethyl ketone oxime, 17.4 kilograms of toluene diisocyanate and triethylamine were added respectively at 40 ° C, and 0.06 kilograms were added in a closed reactor with a stirrer and a thermometer. The temperature was raised to 80°C, and after constant temperature reaction at this temperature for 5 hours, 6 kg of ethylenediamine was added, and then the temperature was raised to 118°C, and reacted for 1 hour. The partially aminated diisocyanate-modified polyether polyol II was obtained.

Embodiment 3

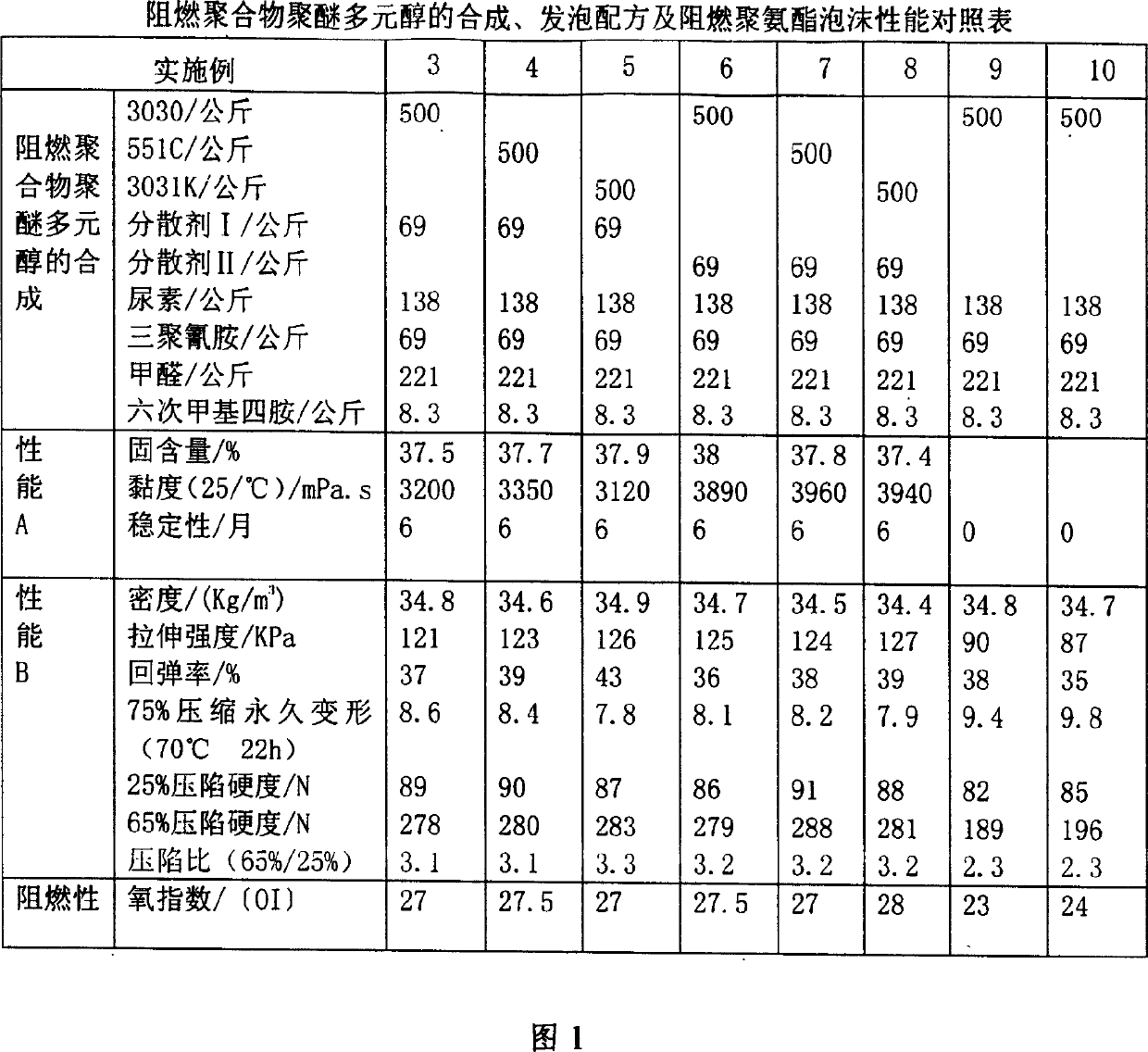

[0082] Embodiment 3: respectively general-purpose polyether polyol 3030, 500 kilograms, partially aminated diisocyanate modified polyether polyol 1, 69 kilograms, 221 kilograms of formaldehyde, 138 kilograms of urea, 69 kilograms of melamine, hexamethylene tetra Add 8.3 kg of amine into a closed 2000-liter reactor with a stirrer and a thermometer, raise the temperature to 80°C, react at a constant temperature at this temperature for 4 hours, and vacuum dry at 92°C for 4 hours to remove volatile components, and obtain resistance For flame-retardant polymer polyether polyol, see Example 3 of the synthesis of flame-retardant polymer polyether polyol, foam formulation and performance comparison table of flame-retardant polyurethane foam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com