Modified urea-formaldehyde adhesive for applewood level E0 medium-density fiberboards and preparation method thereof

A modified urea-formaldehyde and medium-density technology, applied in adhesives, aldehyde/ketone condensation polymer adhesives, adhesive types, etc., to achieve the effects of reasonable formulation, lower activation energy, and lower free formaldehyde content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1 self-made formaldehyde elimination agent formula and production method thereof

[0021] 1. Put in the process water with 28% of the total amount of formaldehyde remover, start stirring, and put in 22% of the total amount of formaldehyde with a content of 37%.

[0022] 2. Add a total of 4.3% of sodium chlorate for the first time, and slightly raise the temperature to 30-35°C to dissolve it completely.

[0023] 3. Add a total amount of 0.04% triethanolamine, and keep HP at 8.0. Then add a total amount of 0.04% borax, and a total amount of 0.23% hexamethylenetetramine for 10 minutes to completely dissolve.

[0024] 4. Add a total amount of 1.2% of the second sodium hypochlorite, keep it for 5 minutes, keep the temperature at 30-35°C, add a total amount of 0.05% sodium hydroxide solution with a content of 30%, and adjust the HP to 8.8.

[0025] 5. Add a total amount of 25% urea for the first time, keep it for 10 minutes, and then add a total amount of 1.2% amm...

Embodiment 2

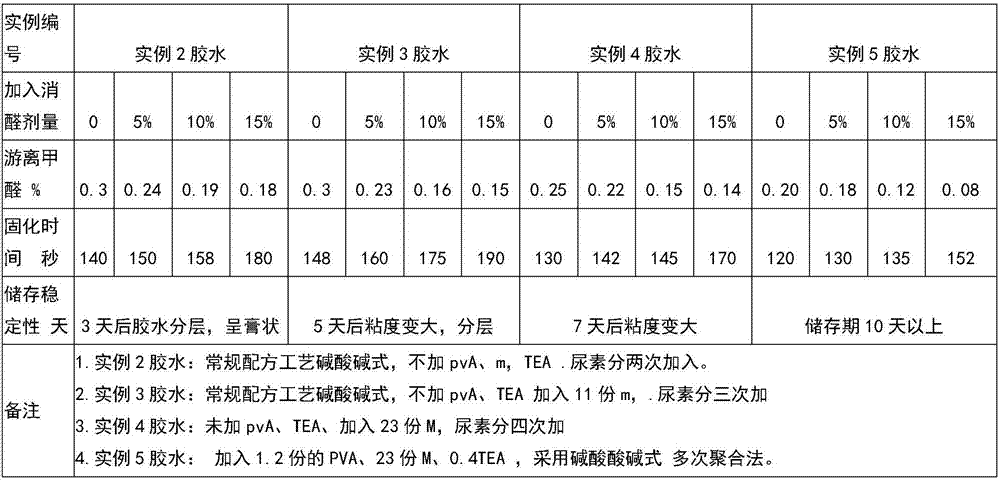

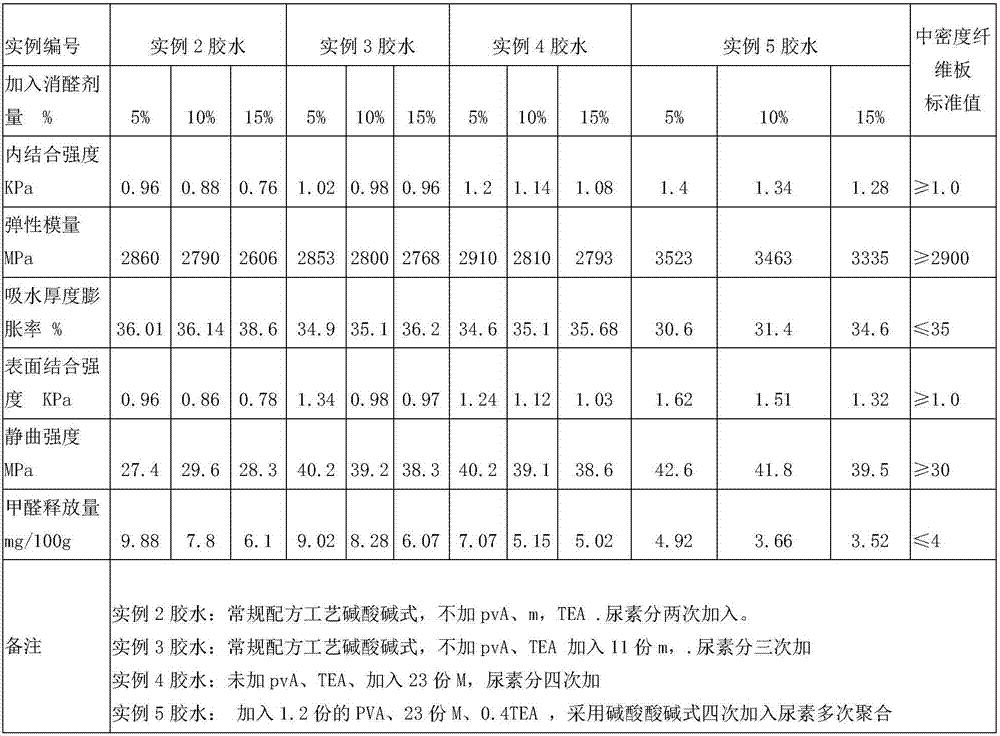

[0028] Embodiment 2 conventional formula general process way:

[0029] 1) It is made of the following materials with a ratio of parts by weight and a molar ratio of 0.84: 537 parts of formaldehyde with a content of 37%, 483 parts of urea, no polyvinyl alcohol (pvA), no melamine (m), no Add triethanolamine (TEA) and use sodium hydroxide, 0.2 part of formic acid (concentration is 20%), 0.4~0.5 part (concentration is 30%) sodium hydroxide as HP regulator composition.

[0030] 2) The process adopts the conventional alkali-acid-alkali method, and the urea is added in two times: the temperature is controlled at 90-93°C, and the heat is kept for 30 minutes after the first urea is added, and then the formic acid solution is added in three times to adjust the HP to 4.5-4.6 to react to At the end point, add sodium hydroxide solution to terminate the reaction, then add urea for the second time to cool down to 38°C and stop the reaction, and the sample is marked as sample A.

Embodiment 3

[0031] Example 3 No addition of polyvinyl alcohol (pvA), no addition of triethanolamine (TEA), addition of 11 parts of melamine (M), conventional practice, urea added in three times, preparation method:

[0032] 1) It is made of the following parts by weight ratio, and the molar ratio is 0.84: 537 parts of formaldehyde, 477 parts of urea, 11 parts of melamine (one-time addition), 0.2 part of formic acid (concentration is 20%), 0.4~0.6 (concentration is 30%) parts of sodium hydroxide are used as HP regulator composition.

[0033] 2) The process adopts the conventional alkaline-acid-alkali formula, without adding polyvinyl alcohol and triethanolamine, and adding urea in three times. Preparation method: adjust the metered formaldehyde to 8.6, add the first batch of urea and melamine to mix and heat up to 93-95°C, keep warm for 30 minutes, add the second urea and keep warm for 30 minutes, then add formic acid solution three times Adjust HP to 5.6 and react for 30-40 minutes. When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com