Oxidized starch modified phenolic resin lumber adhesion agent, preparation method and application thereof

A wood adhesive, phenolic resin technology, applied in starch-derived adhesives, adhesives, aldehyde/ketone condensation polymer adhesives and other directions, can solve the problems of lack of environmental protection resources for synthetic resin adhesives, etc. Energy, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

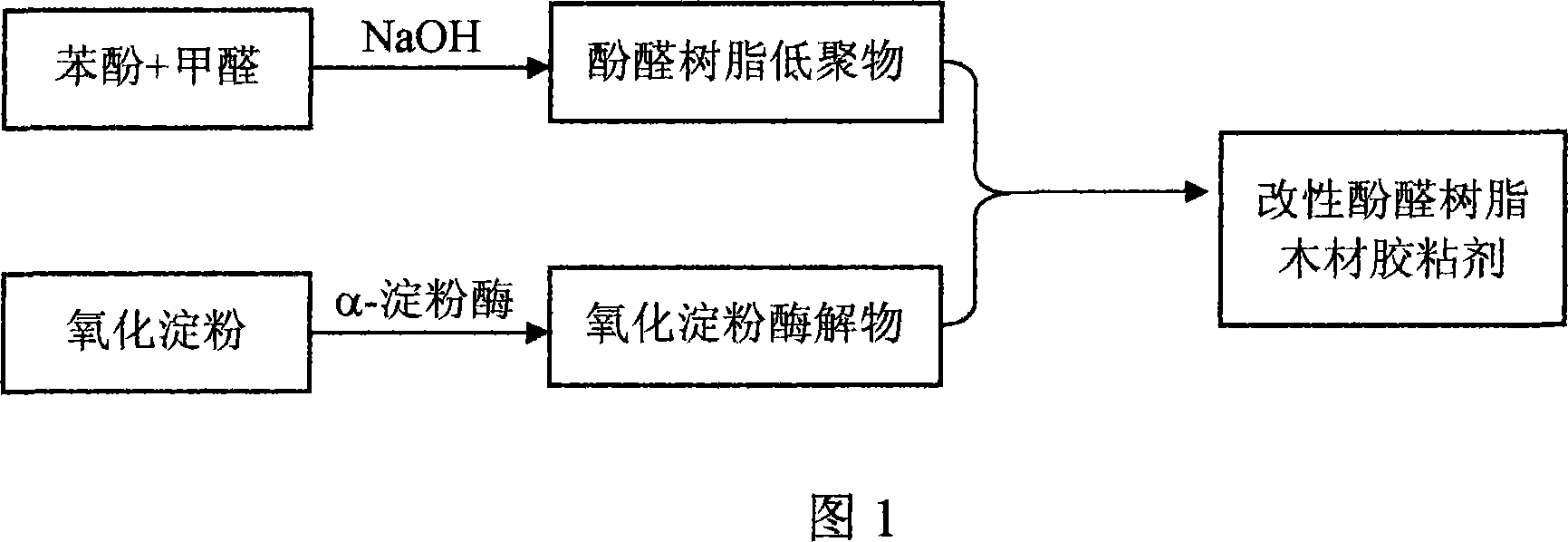

[0030] As shown in Figure 1, the preparation method of utilizing oxidized starch to modify phenolic resin wood adhesive comprises the following steps:

[0031] (1) Synthesis of phenolic resin oligomers. In a three-necked flask equipped with an electric stirrer, a thermometer, and a reflux condenser (a dripping funnel is attached to the top), a molten phenol (37%) and a formaldehyde solution with a molar ratio of 1:2.4 were placed in a constant temperature water bath. While stirring, add 50% sodium hydroxide solution from the dropping funnel to make the pH value 9.5, then heat up to 75°C, keep the temperature for 60 minutes to carry out the addition reaction of formaldehyde and phenol, then heat up to 95°C, and keep the temperature constant for 30 minutes while stirring. , to further condense polymethylol phenol into phenolic resin oligomers. After the reaction is completed, the temperature is lowered to 40 °C for discharging; the water, free phenol and free aldehyde are disti...

Embodiment 2

[0051] Utilize the preparation method of oxidized starch modified phenolic resin wood adhesive, comprising the following steps:

[0052] (1) Synthesis of phenolic resin oligomers. In a three-necked flask equipped with an electric stirrer, a thermometer, and a reflux condenser (a dropping funnel is attached to the top), put the molten phenol (37%) and formaldehyde solution with a molar ratio of 1:2.6 and place them in a constant temperature water bath. While stirring, add 50% sodium hydroxide solution from the dropping funnel to make the pH value at 11, then heat up to 80 °C, keep the temperature for 40 minutes to carry out the addition reaction of formaldehyde and phenol, then heat up to 90 °C, and keep the temperature constant for 40 minutes while stirring. , to further condense polymethylol phenol into phenolic resin oligomers. After the completion of the reaction, the temperature was lowered to 40 °C and the material was discharged. Then, a rotary evaporator was used to d...

Embodiment 3

[0059] Utilize the preparation method of oxidized starch modified phenolic resin wood adhesive, comprising the following steps:

[0060] (1) Synthesis of phenolic resin oligomers. In a three-necked flask equipped with an electric stirrer, a thermometer, and a reflux condenser (a dropping funnel is attached to the top), put the molten phenol (37%) and formaldehyde solution with a molar ratio of 1:1.4 and place them in a constant temperature water bath. While stirring, add 50% sodium hydroxide solution from the dropping funnel to make the pH value 9, then heat up to 60 °C, keep the temperature for 60 minutes to carry out the addition reaction of formaldehyde and phenol, then heat up to 100 °C, and keep the temperature constant for 20 minutes while stirring. , to further condense polymethylol phenol into phenolic resin oligomers. After the completion of the reaction, the temperature was lowered to 40 °C and the material was discharged. Then use a rotary evaporator to distill ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com