Plant nutrient absorption enhancer and preparation method and use thereof

An absorption enhancer, plant nutrient technology, applied in the agricultural field, to achieve the effect of easy access to raw materials, enhanced competitiveness, and promotion of balanced and effective absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

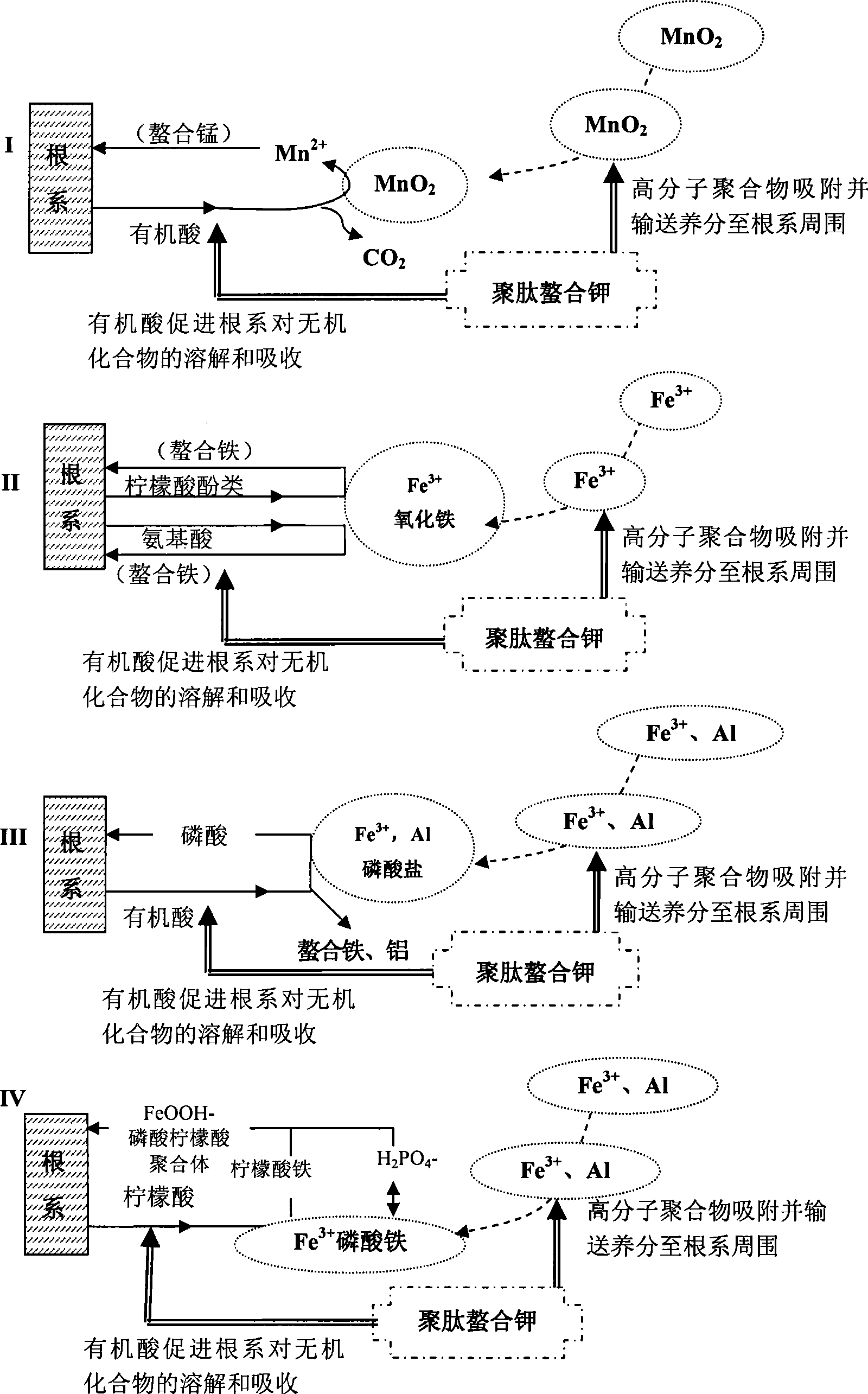

AI Technical Summary

Problems solved by technology

Method used

Image

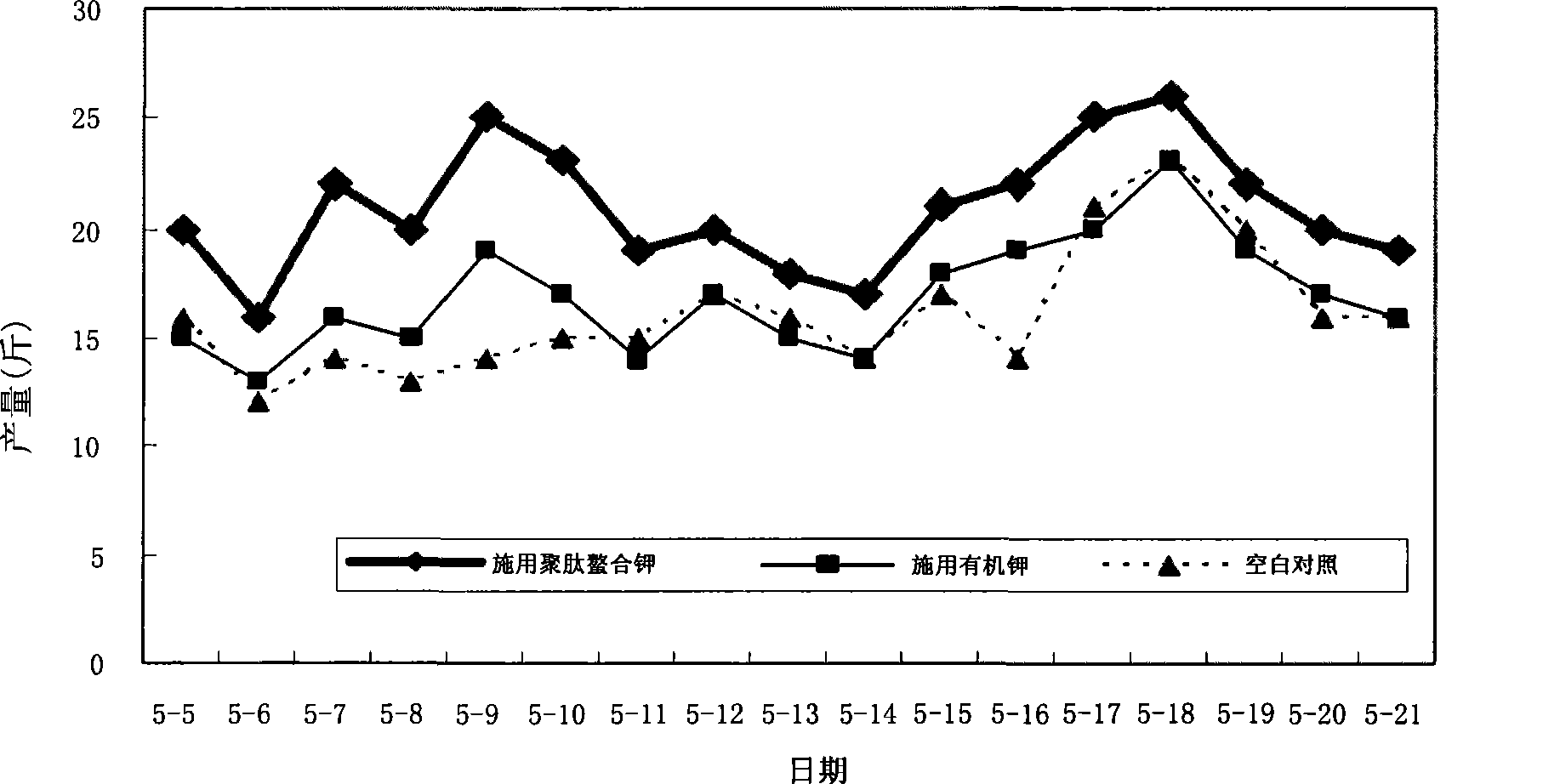

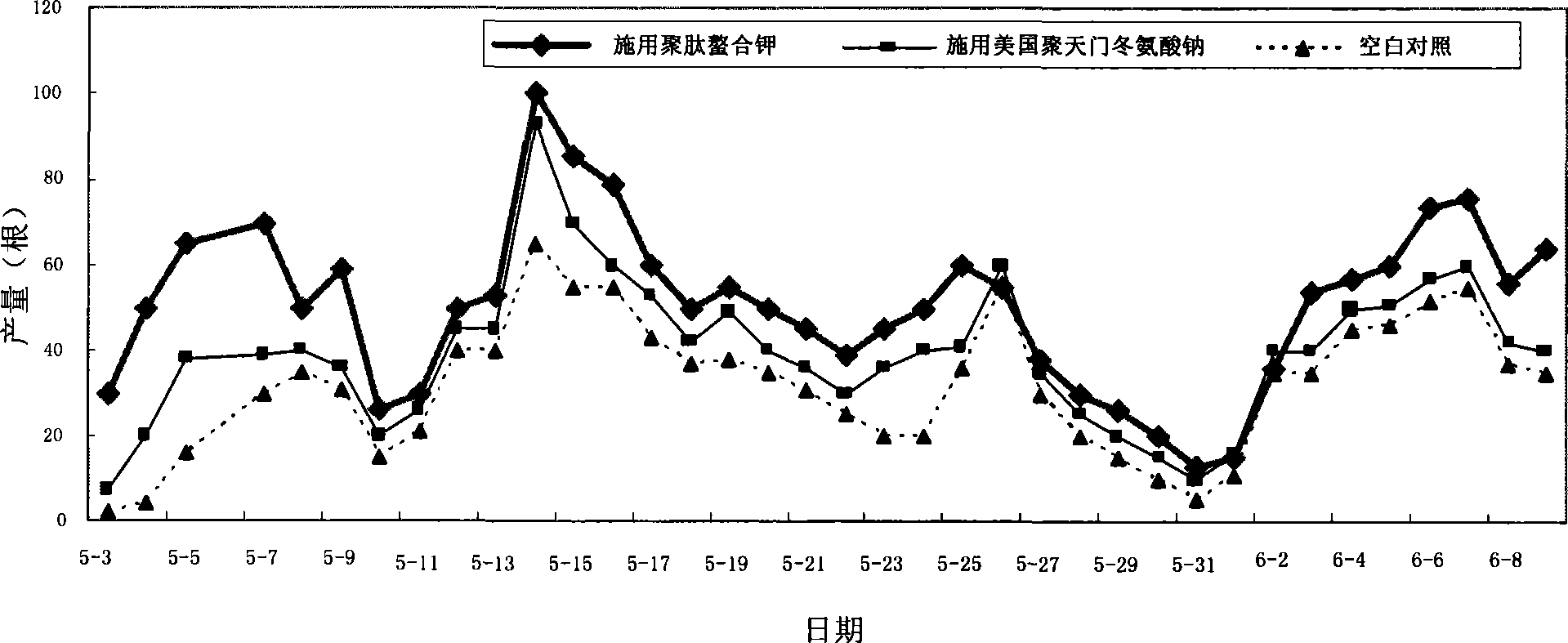

Examples

Embodiment 1

[0040] Add 20.3 kg of polysuccinimide with a molecular weight greater than 5000 to 54.1 kg of water at room temperature, add 18.0 kg of solid potassium hydroxide with a purity greater than 90% while stirring, and control the reaction temperature at about 80°C during the process until the polysuccinimide All imines are dissolved (about 3-4 hours), and then maintain the reaction temperature and add 7.6 kg of citric acid monohydrate to adjust the pH value to 7-8, and obtain 100 kg of brownish-red transparent solution after filtration. The present invention is called "Potassium polypeptide chelate", (the following examples are the same), the active ingredient content is 43%, calculated as potassium salt, the weight ratio of potassium polyaspartate: potassium citrate is 2.9:1.

Embodiment 2

[0042] Add 19 kilograms of polysuccinimide with a molecular weight greater than 5000 to 47 kilograms of water at room temperature, add 24.7 kilograms of solid potassium hydroxide with a purity greater than 90% while stirring, and control the reaction temperature at about 75°C-80°C during the process until After the polysuccinimide is completely dissolved, then maintain the reaction temperature and add 14.4 kg of citric acid monohydrate to adjust the pH value to 7-8, and obtain 100 kg of brownish-red transparent polypeptide chelated potassium solution through filtration. The content of the active ingredient is 53%, calculated as potassium salt, and the weight ratio of potassium polyaspartate: potassium citrate is 1.5:1.

Embodiment 3

[0044] Add 14 kg of polysuccinimide with a molecular weight greater than 5000 to 50 kg of water at room temperature, add 11.6 kg of solid potassium hydroxide with a purity greater than 90% while stirring, and control the reaction temperature at about 85°C during the process until the polysuccinimide After the imine is completely dissolved (about 3-4 hours), then maintain the reaction temperature and add 4 kg of tartaric acid and 20.4 kg of water. After the tartaric acid is completely dissolved, the pH value is 7-8, and the brown-red transparent Polypeptide chelated potassium solution, wherein the active ingredient content is 28%, calculated as potassium salt, and the weight ratio of potassium polyaspartate: potassium tartrate is 3.6:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com