Preparation method of sodium ion battery negative electrode material

A technology for sodium ion batteries and negative electrode materials, applied in battery electrodes, carbon preparation/purification, secondary batteries, etc., can solve the problems that graphite is not suitable for sodium ion intercalation and extraction, etc., to achieve abundant output, wide sources, and improved The effect of electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

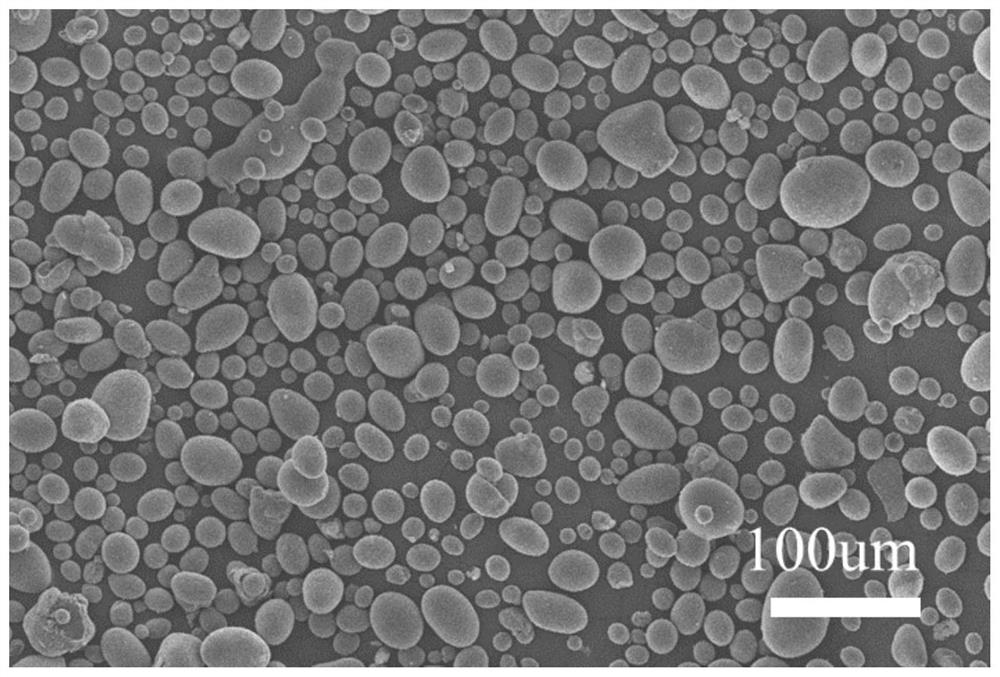

[0025] Weigh 5g of starch and 0.05g of carbon black and add them to the mixer, adjust the stirring speed to 600r / min, after stirring for 1 hour, take the mixture out into the crucible and place it in a muffle furnace, set the temperature at 220°C for 6h for stabilization treatment , put the stabilized sample into a carbonization furnace, raise the temperature to 1000°C at a rate of 2°C / min in a nitrogen atmosphere and keep it for 1h, then cool to room temperature, take out the carbonized sample, and obtain a starch-based sodium ion battery Negative material.

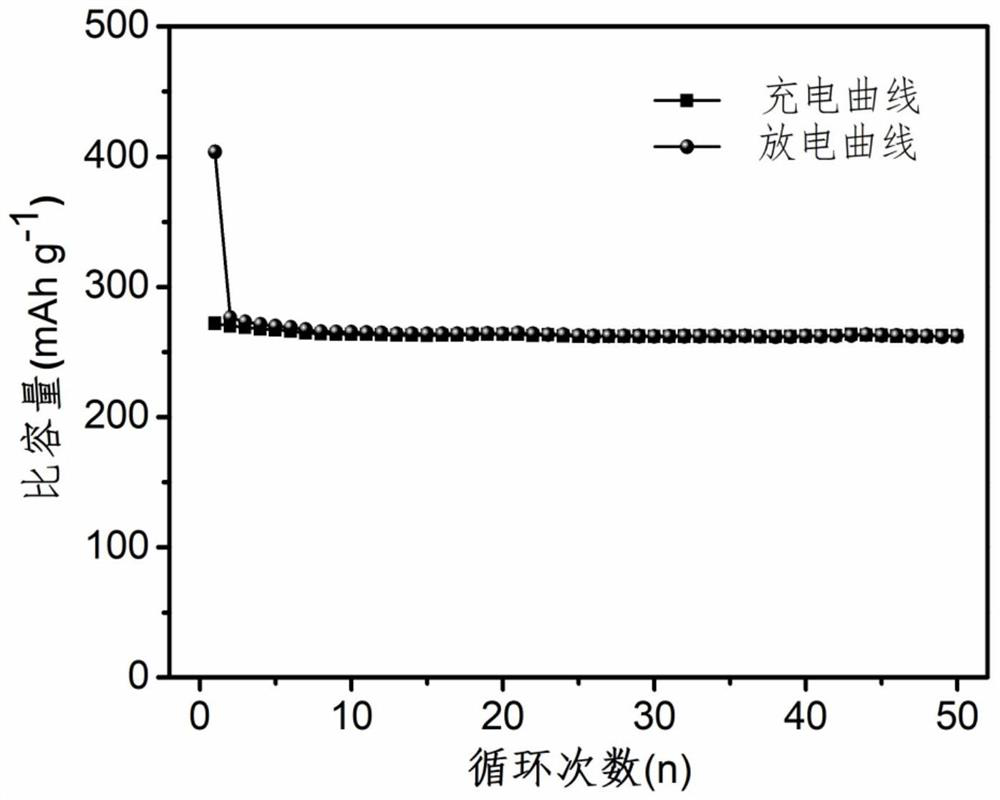

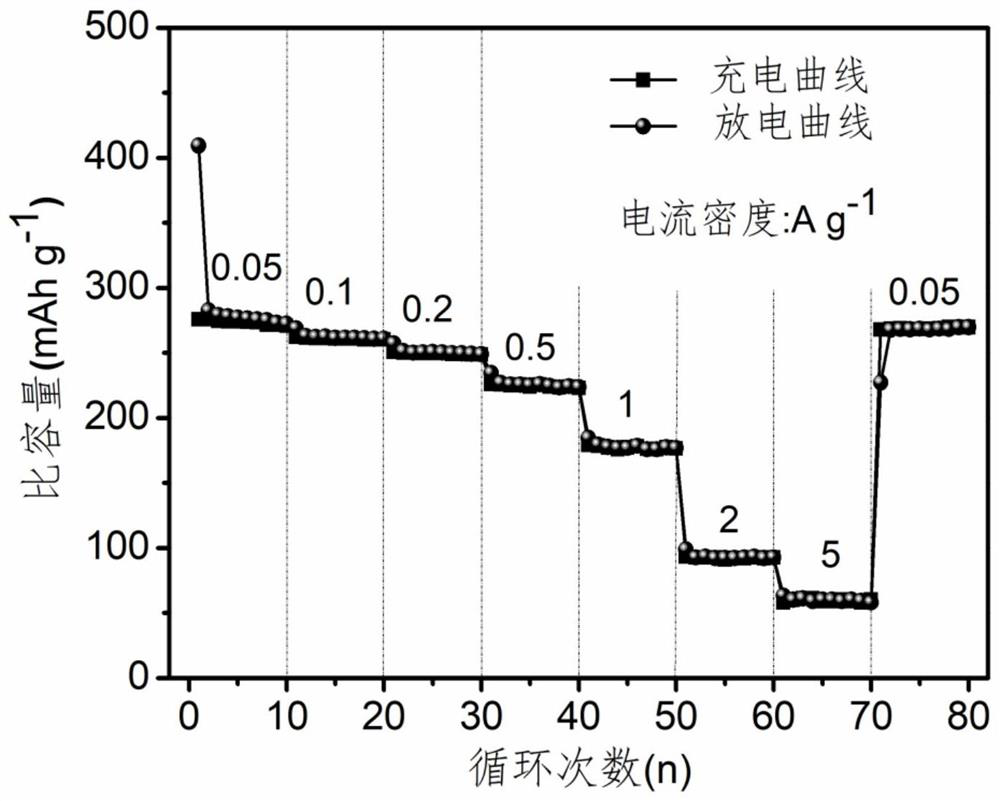

[0026] The obtained starch-based carbon microspheres were assembled into a sodium ion battery, and the working electrode was prepared according to the ratio of sample: conductive agent: binder = 80:10:10, and the metal sodium sheet was used as the counter electrode, and its electrochemical performance was tested. The test condition is 25°C, the current density is 0.05-5A / g, and the voltage range is 0.01-2.8V.

[0027] a...

Embodiment 2

[0029] Weigh 5g of starch and 0.5g of carbon black and add them to the mixer, adjust the stirring speed to 600r / min, after stirring for 1 hour, take the mixture out into the crucible and place it in a muffle furnace, set the temperature at 220°C for 6h for stabilization treatment , put the stabilized sample into a carbonization furnace, raise the temperature to 1000°C at a rate of 2°C / min in a nitrogen atmosphere and keep it for 1h, then cool to room temperature, take out the carbonized sample, and obtain a starch-based sodium ion battery Negative material. Under the current density of 0.05A / g, after 50 cycles, the reversible specific capacity is 265.3mAh / g, and the capacity retention rate is 97.2%.

Embodiment 3

[0031] Weigh 5g of starch and 0.005g of carbon black and add them to the mixer, adjust the stirring speed to 600r / min, after stirring for 1 hour, take the mixture out into the crucible and place it in a muffle furnace, set the temperature at 220°C for 6h for stabilization treatment , put the stabilized sample into a carbonization furnace, raise the temperature to 1000°C at a rate of 2°C / min in a nitrogen atmosphere and keep it for 1h, then cool to room temperature, take out the carbonized sample, and obtain a starch-based sodium ion battery Negative material. Under the current density of 0.05A / g, after 50 cycles, the reversible specific capacity is 259.5mAh / g, and the capacity retention rate is 94.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com