Process for preparing acrylate resin for powder paint

A technology of acrylic resin and powder coating, applied in the direction of powder coating, coating, etc., can solve the problems of environmental pollution, complex process, difficult product quality, etc., and achieve the effect of good mechanical properties, simple process, and strong outdoor durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

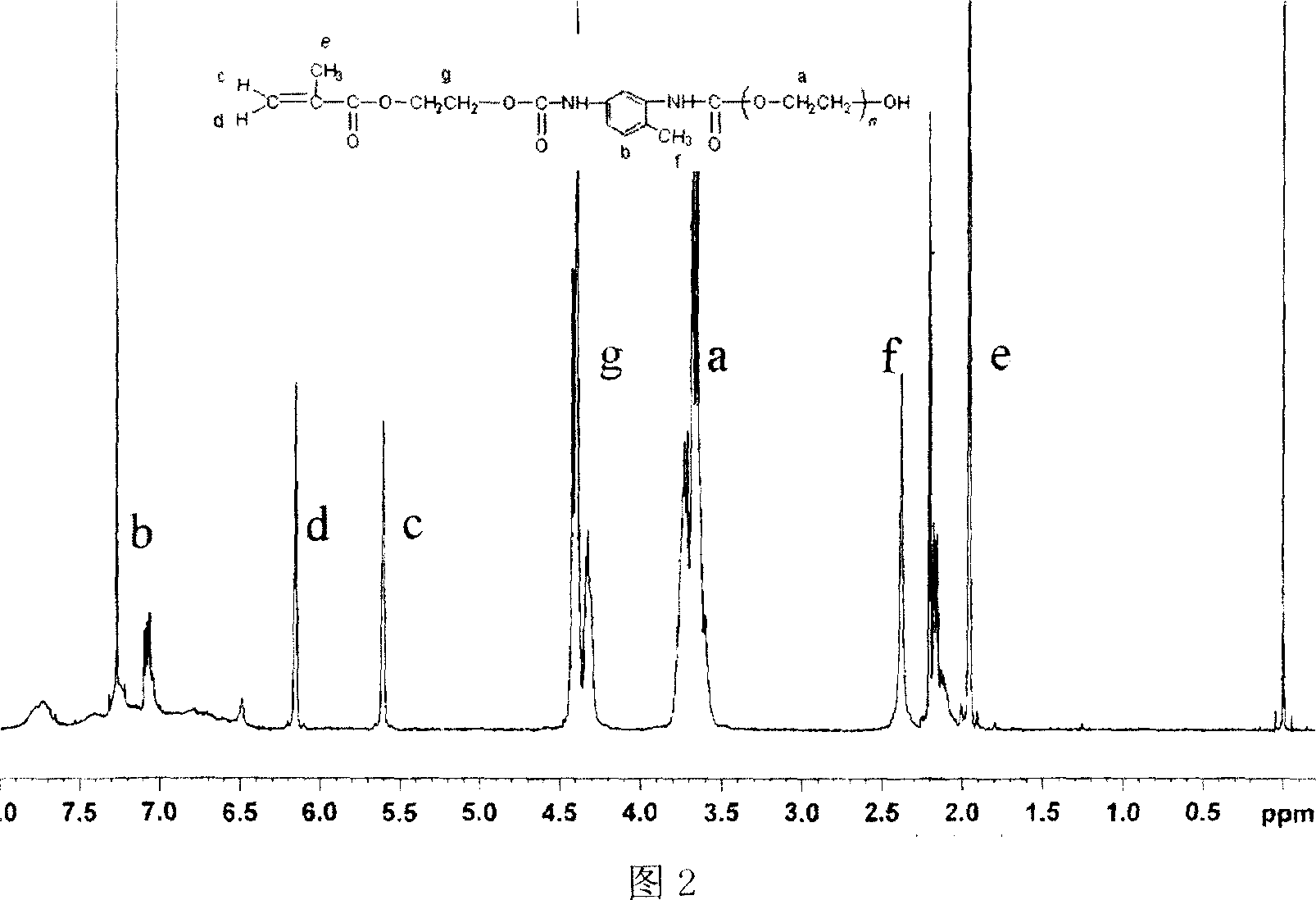

[0041] Preparation of Polyurethane Type Macromonomer Dispersant

[0042] Place a 250ml four-necked bottle in a constant temperature water bath, and assemble a series of devices such as a spherical condenser, an anchor stirring rod, a thermometer, and a nitrogen conduit on the four-necked bottle. 17.42g TDI was added into the four-necked flask, and 50.0g MMA (English abbreviation for methyl methacrylate, the same below) was added to the four-necked flask at the same time as a reaction diluent, and a drop of dibutyltin dilaurate was added as a catalyst. The temperature of the water bath was controlled at 30° C., nitrogen and condensed water were introduced, and the stirrer was started. Connect a constant-pressure dropping funnel to the condenser, add 13.01g HEMA into the dropping funnel, start to drop it into the four-necked flask slowly, and finish the dropping after 30 minutes, and react at a constant temperature of 30°C for 3 hours to reach the theoretical -NCO content, to o...

Embodiment 2

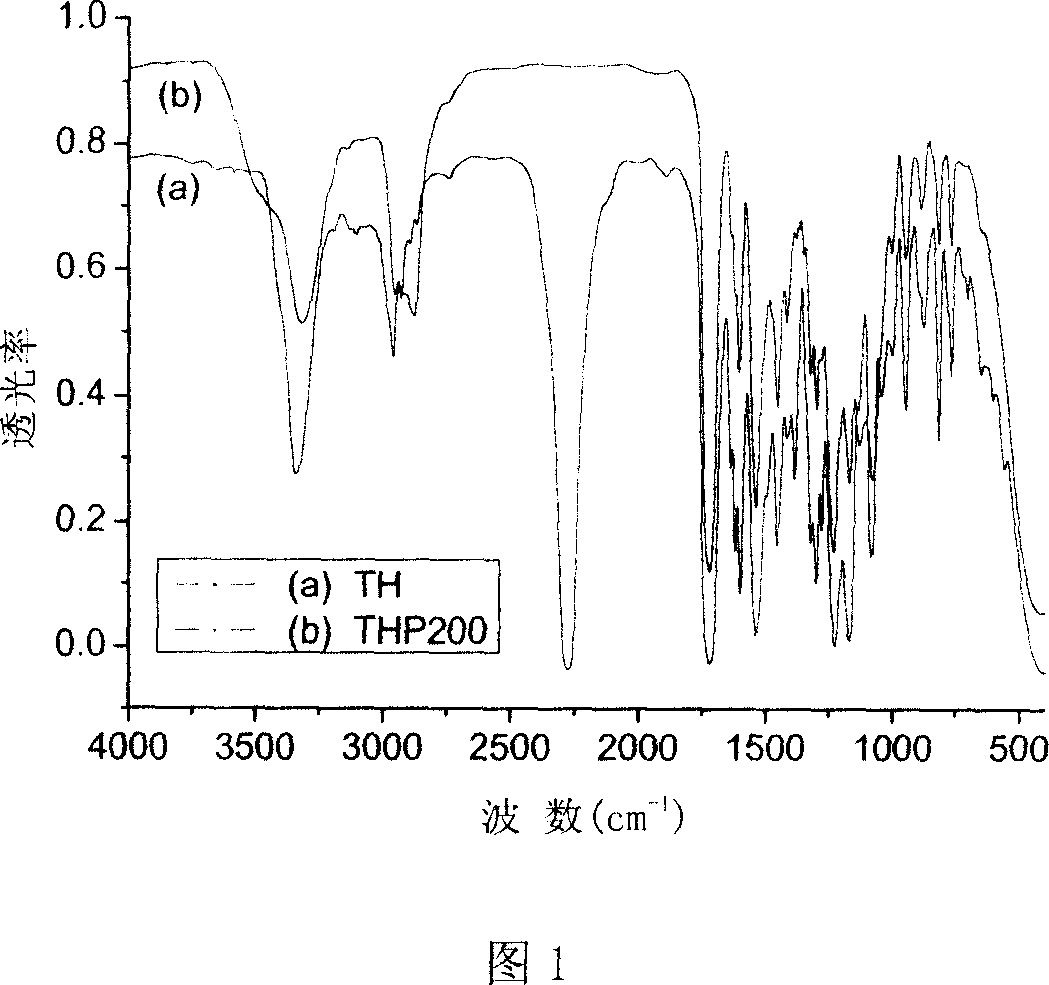

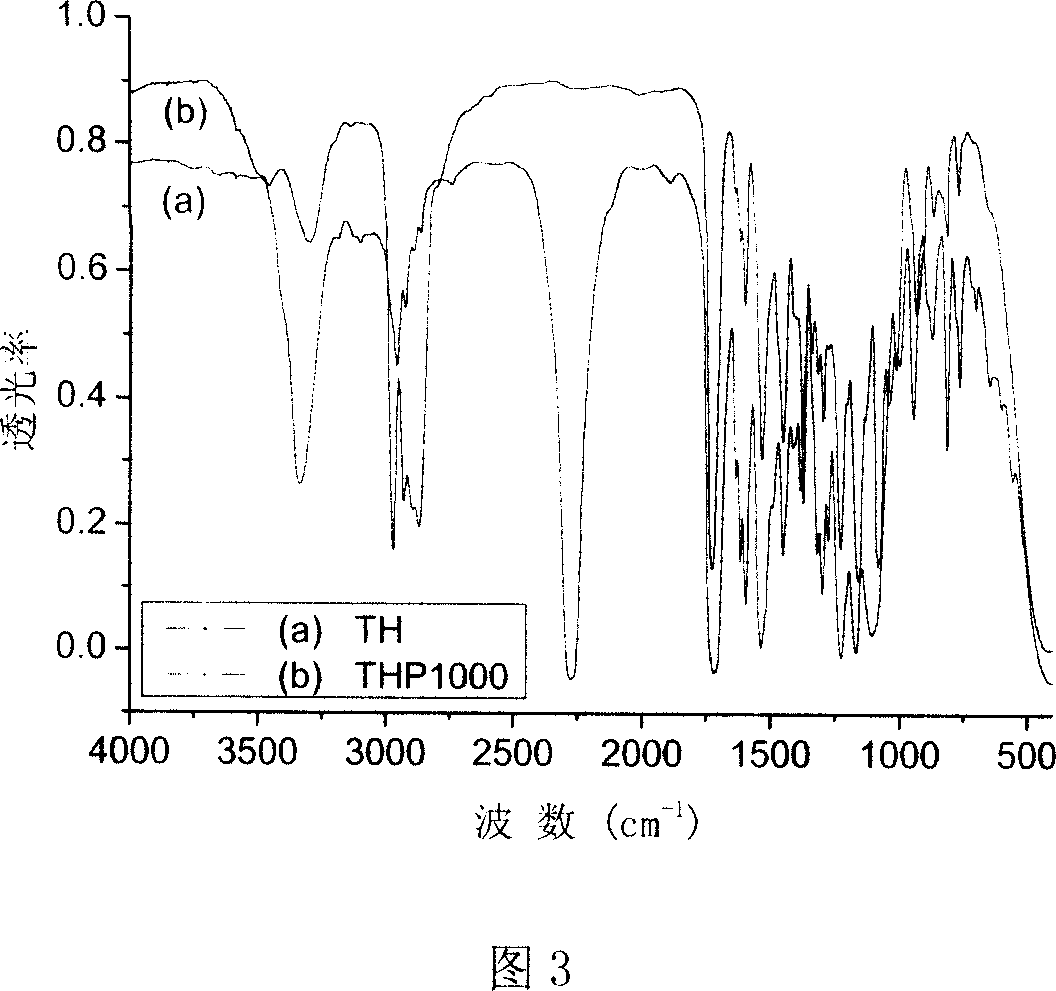

[0044] Assemble the instrument as in Example 1, add 8.71g TDI to the four-necked flask, add 50.0g MMA to the 250ml four-necked flask at the same time, add a drop of dibutyltin dilaurate as a catalyst, control the temperature of the water bath at 30°C, and pass Nitrogen and condensed water, start the stirrer, connect a constant pressure dropping funnel on the condenser, add 6.51g HEMA into the dropping funnel, start to slowly add dropwise to the four-necked bottle, after 30 minutes, the dropwise addition is completed, and then React at a constant temperature of 30°C for 3 hours to reach the theoretical -NCO content, and obtain the first step product TH with a double bond at one end and -NCO at the other end. Afterwards, 50.0 g of polyoxypropylene diol 1000 was added at one time and reacted at a constant temperature of 30° C. for 3 hours to obtain a colorless and transparent polyurethane macromonomer THP1000. Fig. 3 (a) is the infrared spectrum of the reaction product of HEMA an...

Embodiment 3

[0046] Synthesis of Epoxy Acrylic Resin

[0047] (1) Reactant ingredients

[0048] Reactant composition and proportioning are: dispersion medium is 50.0g dehydrated alcohol and 30.0g deionized water; Functional monomer glycidyl methacrylate (represented with GMA below) 3.0g; Free radical initiator is azobisisobutyronitrile (represented with AIBN below) 0.30g; Monomer THP200 1.5g; chain transfer agent 0.

[0049] (2) Dispersion polymerization reaction

[0050] ① Preparation of reactant mixture

[0051] Accurately weigh GMA3.0g, MMA6.0g and BA1.0g, all of which have been distilled under reduced pressure to remove the polymerization inhibitor, put the above three monomers in a 50ml beaker and mix evenly, and add the synthesized dispersant THP2001.5g to the above The three mixed monomers were vigorously stirred and mixed evenly, and 0.30 g of azobisisobutyronitrile recrystallized from ethanol was weighed, added to the mixed monomers, and stirred until completely dissolved into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com