Method for stably dispersing graphene or/and carbon nanotubes in organic solvent

A technology of carbon nanotubes and organic solvents, applied in the field of nanomaterials, can solve problems such as unstable surface modification of graphene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

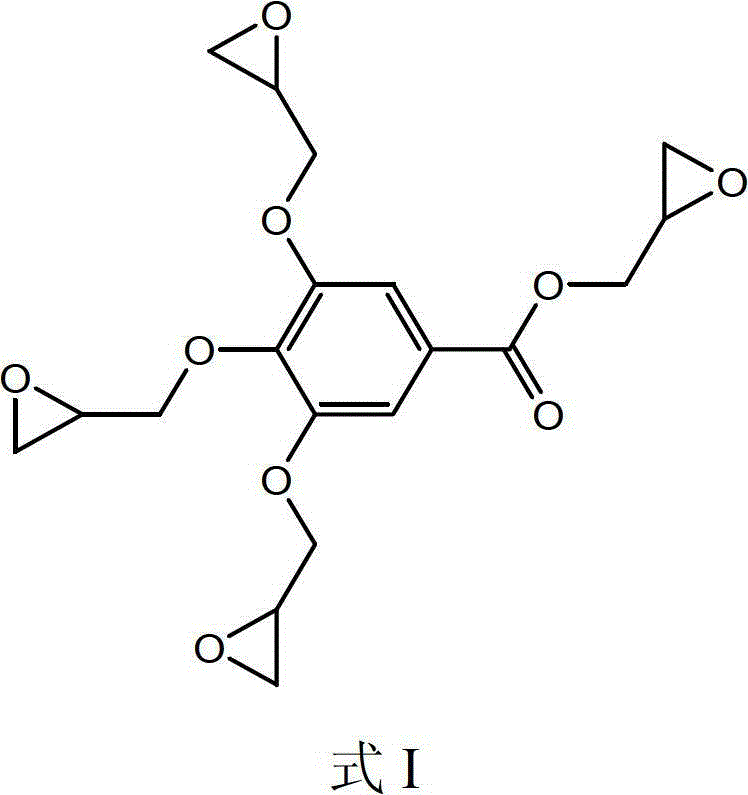

[0025] The bio-based gallic acid epoxy resin was prepared according to the specification example 1 of the Chinese invention patent application with the application number 201110118776.X, which is a compound with the structure of formula I.

[0026]

Embodiment 1

[0028] Dissolve 0.01 gram of multilayer graphene and 0.01 gram of the bio-based gallic acid epoxy resin prepared in Preparation Example 1 into 10 mL of acetone, and ultrasonically disperse for 9 hours at an ultrasonic frequency of 20 KHz and an ultrasonic power of 100 W to obtain a dispersed Uniform multilayer graphene in acetone (graphene dispersion).

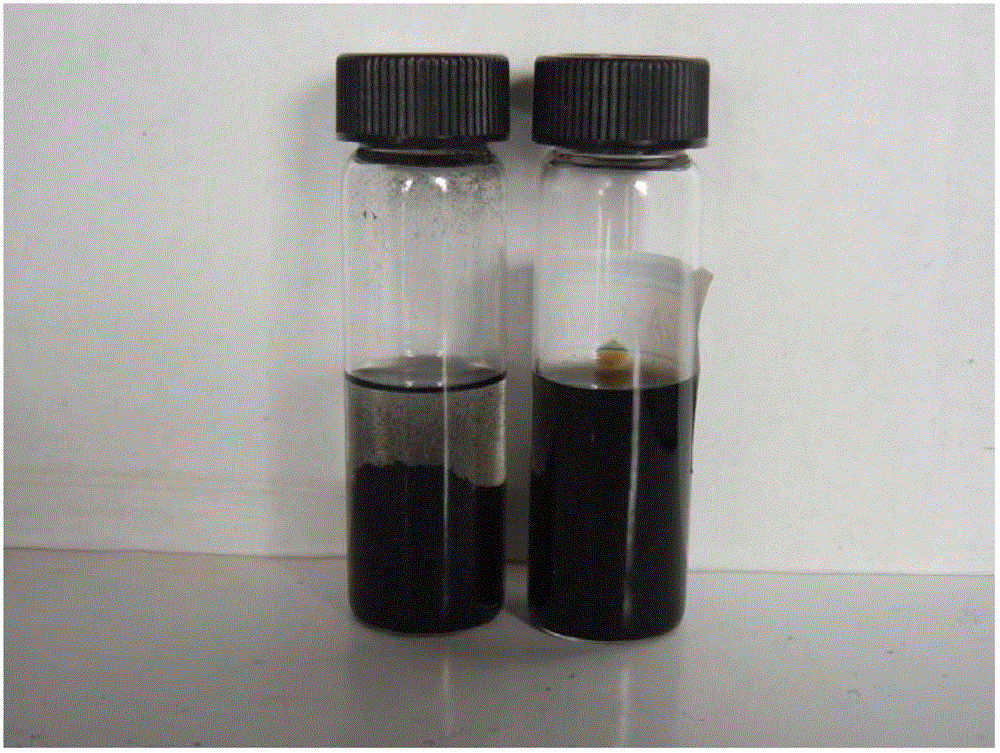

[0029] After the multilayer graphene acetone solution was left standing for 12 hours, no precipitation or stratification occurred, indicating that graphene was uniformly and stably dispersed in acetone, as follows figure 1 Shown in the reagent bottle on the right. Mix the above-mentioned multilayer graphene acetone solution (10 mL) with 100 g of commercially available epoxy resin (Dow Chemical, brand D.E.R331) and 60 g of curing agent hexahydrophthalic anhydride, and remove the solvent in a vacuum oven at 30 °C for 60 minutes , and then cured at 80°C for 2h, 130°C for 2h and 160°C for 2h, respectively, to obtain the multilaye...

Embodiment 2

[0032] Dissolve 1 gram of carbon nanotubes with a diameter of 10 nm and 6 grams of the bio-based gallic acid epoxy resin prepared in Preparation Example 1 into a mixed solvent consisting of 5 mL of dichloromethane and 5 mL of chloroform, and the total amount of the mixed solvent is 10 mL. Under the condition of frequency of 90KHz and ultrasonic power of 150W, ultrasonic dispersion is performed for 30 minutes to obtain a uniformly dispersed carbon nanotube dispersion.

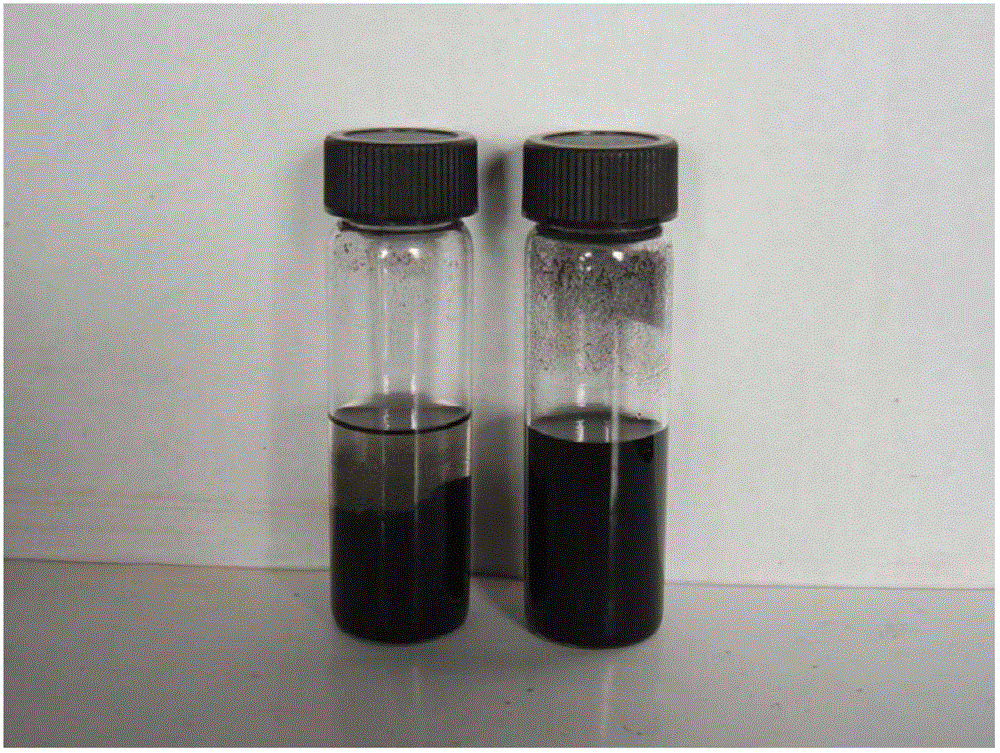

[0033] After the carbon nanotube dispersion was left to stand for 12 hours, no precipitation or delamination occurred, indicating that the carbon nanotubes were uniformly and stably dispersed in the mixed solvent, as follows figure 2 Shown in the reagent bottle on the right. The above carbon nanotube dispersion (10 mL) was mixed with 100 g of commercially available epoxy resin (Dow Chemical, brand D.E.R331) and 60 g of curing agent hexahydrophthalic anhydride, and the solvent was removed in a vacuum oven at 30 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com