Nitrogen-doped porous carbon material based on polyvinylidene chloride and its preparation method and application

A polyvinylidene chloride, nitrogen-doped porous carbon technology, applied in the field of porous carbon materials, can solve the problems of complex production process, influence on capacitor performance, increase in influencing factors, etc., achieves good overall stability of the material, and is easy to realize industrialization , The effect of uniform distribution of nitrogen elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

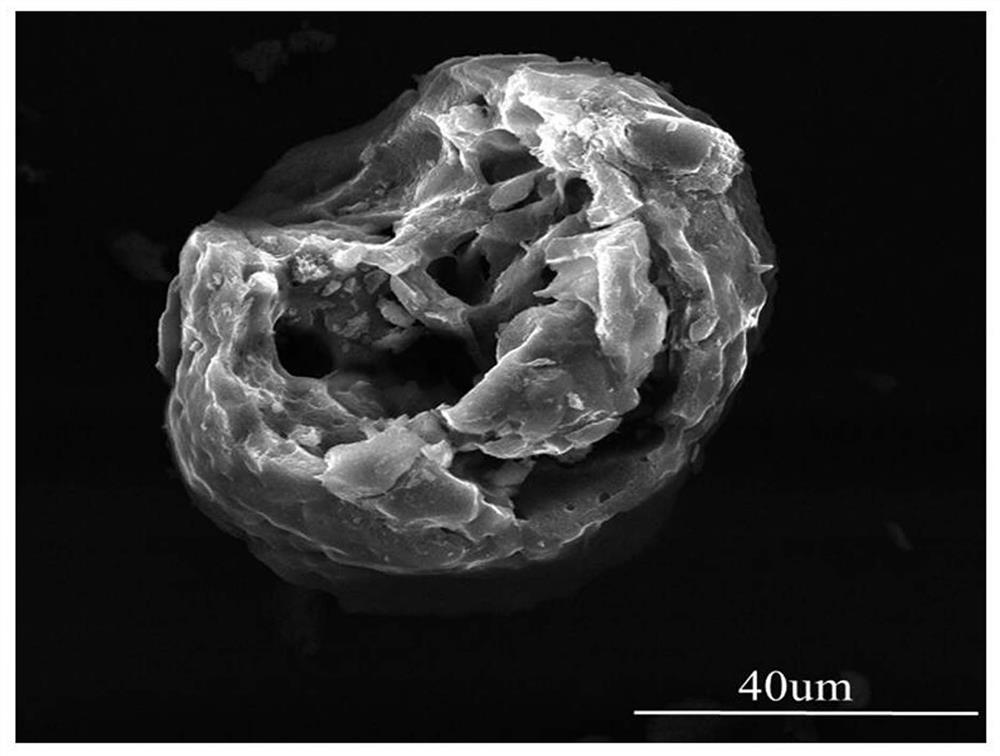

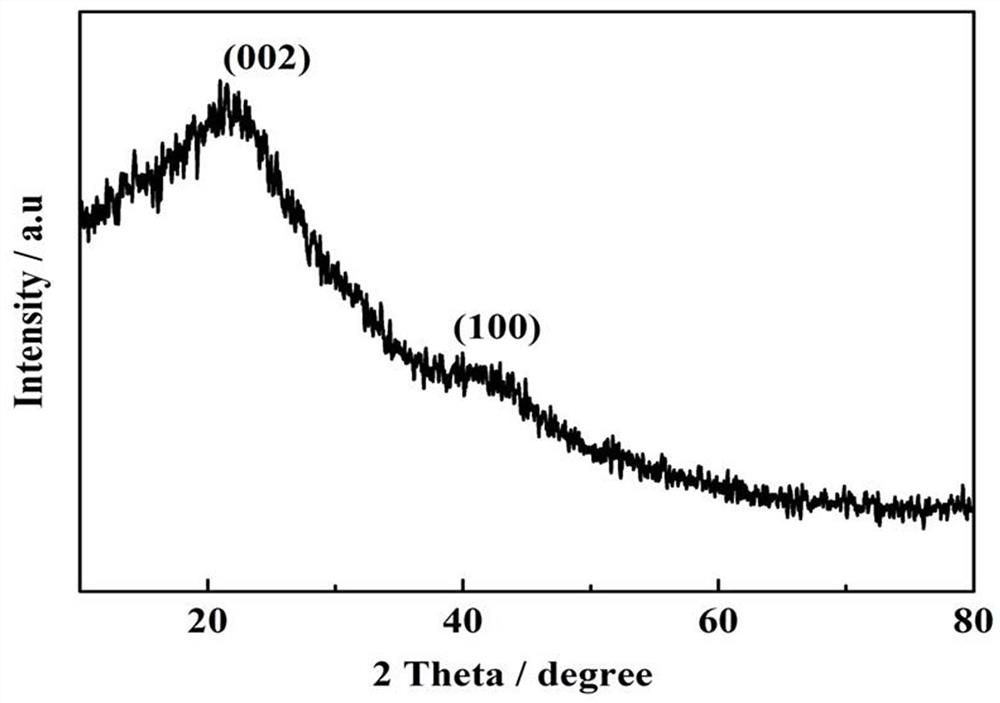

[0043] Preparation method of nitrogen-doped porous carbon material based on polyvinylidene chloride:

[0044] Step 1) One-step dechlorination and nitrogen doping, at room temperature, mix 2g of polyvinylidene chloride powder with 4ml of ethylenediamine to fully react, then dehalogenate, and dry in a blast drying oven at 110°C to obtain nitrogen-containing carbon precursor;

[0045] Step 2) calcination and activation of the carbon precursor, the nitrogen-containing carbon precursor obtained in step 1) and the basic inorganic substance are mixed and ground uniformly in a certain mass ratio of 1.0:3.0, and then placed in a tube furnace under the protection of a nitrogen atmosphere. The activation temperature was 600 °C, and the activation time was 2 h, and the porous carbon material was obtained by calcination and activation. The obtained porous carbon material was soaked in 1M hydrochloric acid solution, washed with distilled water until neutral, and then suction filtered. Afte...

Embodiment 2

[0057] The preparation method of the nitrogen-doped porous carbon material based on polyvinylidene chloride is the same as that in Example 1.

[0058] Based on the application of polyvinylidene chloride nitrogen-doped porous carbon material, the unspecified steps are the same as in Example 1, except that: PVDC(g):ethylenediamine(mL)=1:1.

[0059] Based on the specific capacity test of polyvinylidene chloride nitrogen-doped porous carbon materials, the results are as follows Figure 10 shown, when the current density is 0.5 A g -1 When the capacitance value reaches 447F g -1 .

Embodiment 3

[0061] The preparation method of the nitrogen-doped porous carbon material based on polyvinylidene chloride is the same as that in Example 1.

[0062] Based on the application of the polyvinylidene chloride nitrogen-doped porous carbon material, the unspecified steps are the same as those in Example 1, except that: PVDC(g):ethylenediamine(mL)=1:3.

[0063] Based on the specific capacity test of polyvinylidene chloride nitrogen-doped porous carbon materials, the results are as follows Figure 10 shown, when the current density is 0.5 A g -1 When the capacitance value reaches 401F g -1 .

[0064]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com