Preparation method of nanoporous gold/manganese dioxide composite electrode material

A nanoporous gold and manganese dioxide technology, which is applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve the problems of low mechanical stability, poor electrical conductivity, and difficulty in reaching the specific capacitance value, etc., and achieve coating The effects of uniform controllability, good shape retention and good specific capacitance characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A preparation method of nanoporous gold / manganese dioxide composite electrode material, comprising the following steps:

[0026] (1) Preparation of nanoporous gold films

[0027] choose Au 35 Ag 65 Alloy thin film (that is, atomic ratio of 7:13), cut the alloy thin film to an appropriate size, place the alloy thin film in a nitric acid solution with a concentration of 12M-16M (M is mol / L) at room temperature, and use chemical methods for dealloying treatment 30-120 minutes, thereby preparing a nanoporous gold film with a nanoporous structure. The nanoporous gold thin film has different pore size ranges with the change of dealloying time and the concentration of the dealloying etchant, and the average pore size is usually in the range of 30nm to 60nm, showing hierarchy under different process conditions. The prepared nanoporous gold film was first washed with deionized water, then washed with absolute ethanol, and then the clean nanoporous gold film was dried at room ...

Embodiment 1

[0031] A preparation method of the nanoporous gold / manganese dioxide composite electrode material of the present invention comprises the following steps:

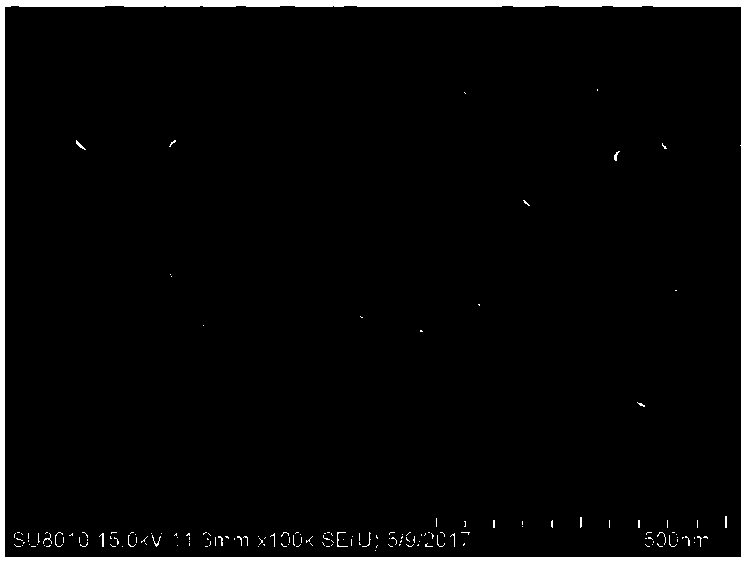

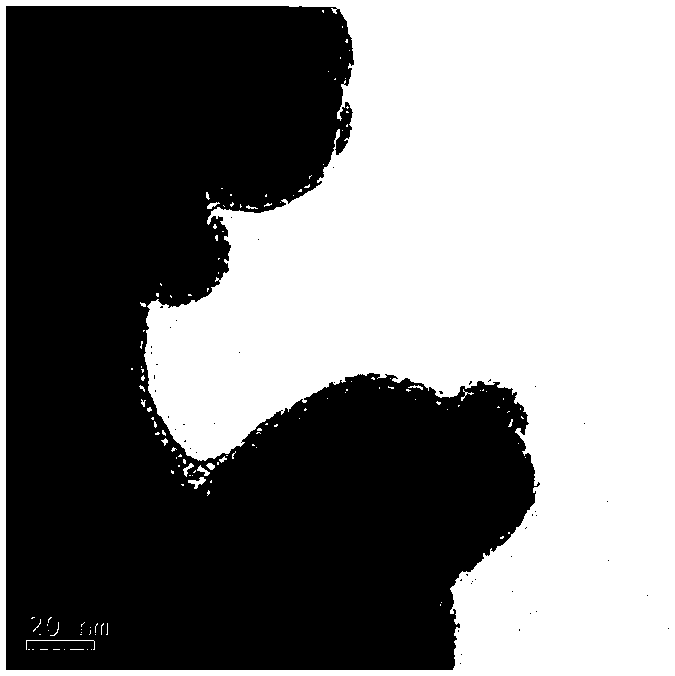

[0032] (1) Preparation of nanoporous gold film: Au with a thickness of 100 nm was selected 35 Ag 65 Alloy thin film (atomic ratio), cut it to 1×1cm 2 size, the alloy thin film was placed in a 16M nitric acid solution at room temperature for dealloying treatment for 30 minutes, and after the dealloying was completed, a nanoporous gold thin film was obtained. The film was washed with deionized water for 30 minutes, replaced with deionized water and repeated for 4 times, and then washed with absolute ethanol. After cleaning, it was dried at room temperature for 12 hours for use. The obtained nanoporous gold film had the following microscopic morphology figure 1 As shown, the average pore size of the nanoporous gold film is 30 nm.

[0033] (2) Preparation of nanoporous gold / manganese dioxide composite electrode material: put...

Embodiment 2

[0035] A preparation method of the nanoporous gold / manganese dioxide composite electrode material of the present invention comprises the following steps:

[0036] (1) Preparation of nanoporous gold film:

[0037] Choose Au with a thickness of 100nm 35 Ag 65 Alloy thin film (atomic ratio), cut to 2×1cm 2 size, place the alloy film in a 12M nitric acid solution at room temperature for dealloying treatment for 90 minutes. After the dealloying is completed, a nanoporous gold film is obtained. The film is washed with deionized water for 30 minutes, and the deionized water is replaced for repeated cleaning. 4 times, then washed with anhydrous ethanol, cleaned and dried at room temperature for 12 hours for use. The average pore size of the nanoporous gold film is 50 nm.

[0038] (2) Preparation of nanoporous gold / manganese dioxide composite electrode material: put the dried nanoporous gold film into the reaction chamber of the atomic layer deposition equipment, pass nitrogen gas a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com