Preparation method and application of heteroatom-doped porous carbon nano-tube

A technology of nanotubes and porous carbon, applied in the direction of carbon nanotubes, nanotechnology for materials and surface science, nanocarbons, etc., can solve the problems of reduced electrical conductivity, inappropriate electrochemical fields, etc., and achieve specific capacitance Large, high yield, good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment includes the following steps:

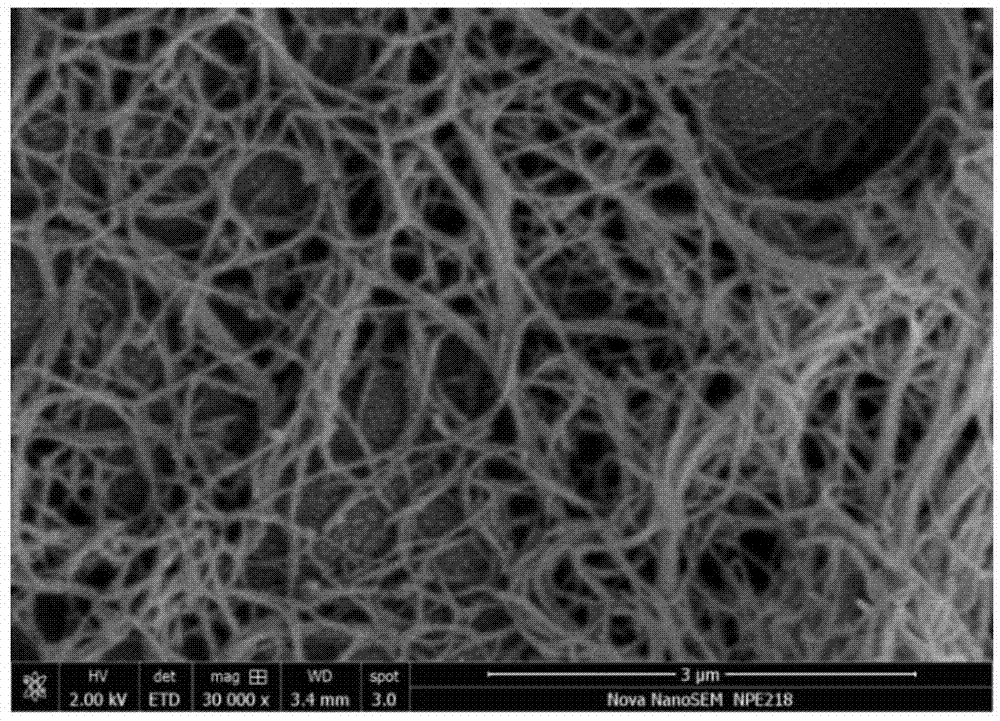

[0032] 1) Preparation of polyphosphazene nanotubes: add 0.5g of hexachlorocyclotriphosphazene and 1.08g of 4,4,'-dihydroxydiphenylsulfone into a 250mL flask, then add 100mL of anhydrous tetrahydrofuran, stir to dissolve, and then add The 50 tetrahydrofuran solution in which 2 mL of triethylamine was dissolved was added to the above reactor, and the reaction was vigorously stirred with an ultrasonic cleaner for half an hour at 25 ° C. After the reaction was completed, the crude product was filtered and washed three times with ethanol and then with deionized water. three times, and dried to obtain white polyphosphazene nanotubes.

[0033] 2), weigh 0.5g of polyphosphazene nanotube powder in a porcelain boat, put it into a tube furnace, pass inert gas nitrogen for 1 hour to replace the air in the tube cavity, and then heat up to 500 °C at a heating rate of 5 °C / min. ℃, constant temperature at 500 ℃ for 5 hours, then heated t...

Embodiment 2

[0041] The difference from Example 1 is that the maximum carbonization temperature is 800°C.

[0042] Figure 7 Nitrogen adsorption curve and pore size distribution curve of carbon nanotubes obtained by carbonization at 800°C under the conditions of Example 2.

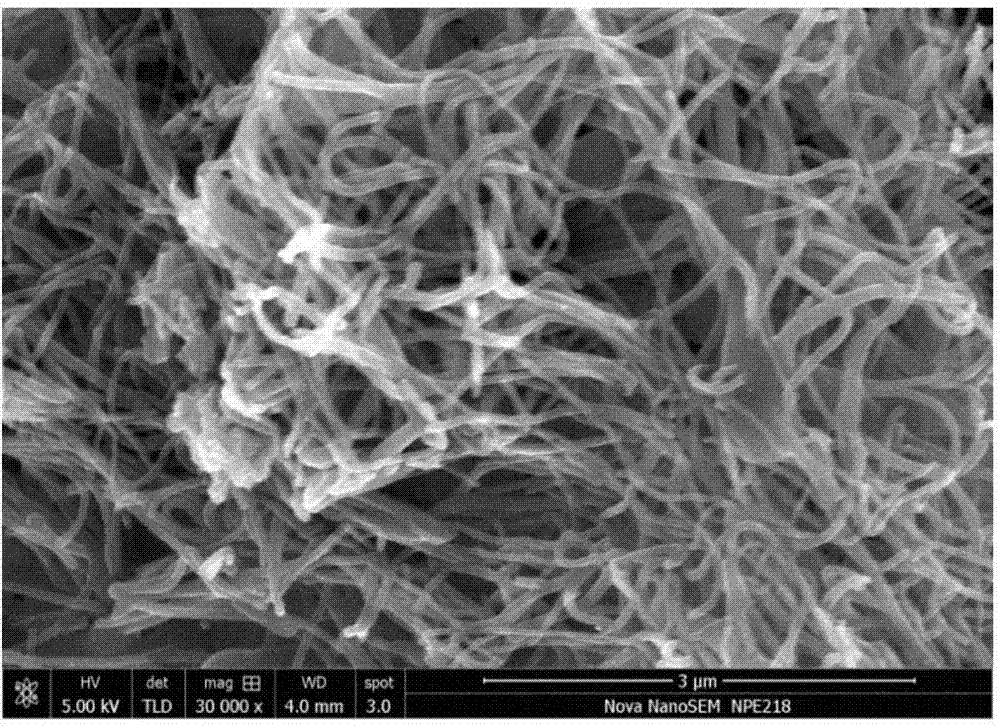

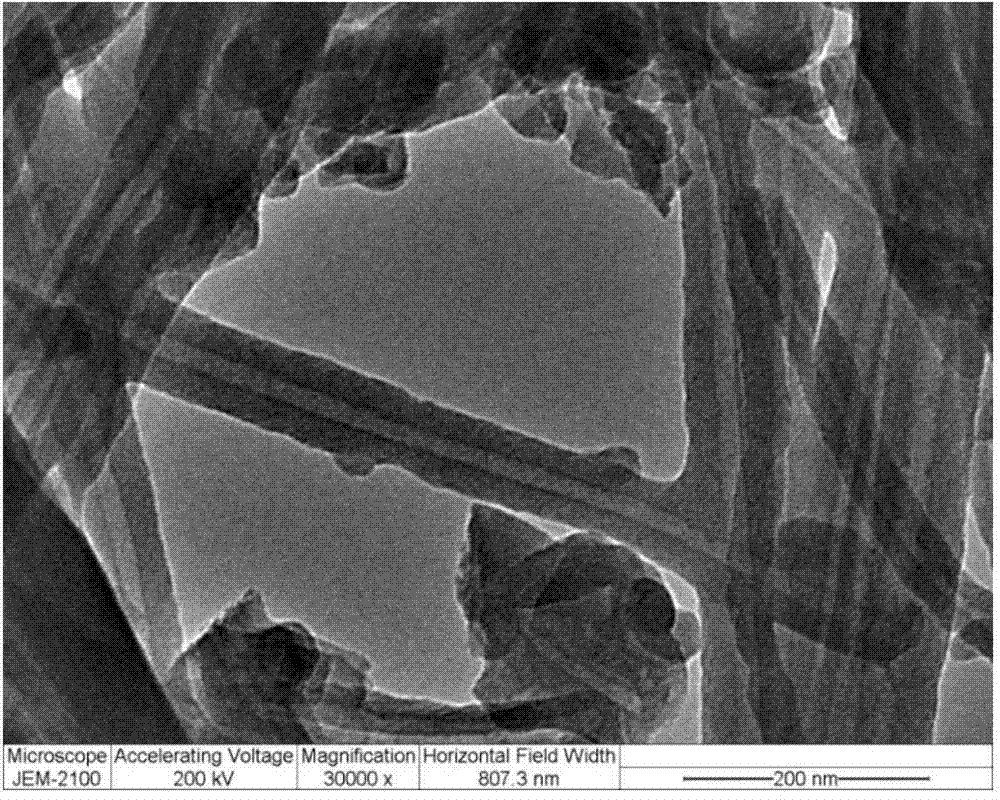

[0043] The material structure analysis shows that the prepared heteroatom-doped porous material still has a good tubular morphology, which is consistent with the morphology of the precursor polyphosphazene nanotubes. After carbonization at 800℃, the specific surface area of the material is 520.7m 2 / g, the porosity is 0.353cm 3 / g. The pore size distribution is narrow, with a pore size of about 4 nm.

[0044] Figure 8 It is a cyclic voltammogram of carbon nanotubes obtained by carbonization at 800° C. under the conditions of Example 2 at a scan rate of 2 mv / s. Electrochemical analysis of the material shows that the specific capacity of the material obtained by carbonization at 800 °C reaches 168 F / g at a scan ...

Embodiment 3

[0046] The difference from Example 1 is that the inert gas used is argon, and the heating rate is 3°C / min.

[0047] The material structure analysis shows that the prepared heteroatom-doped porous material still has a good tubular morphology, which is consistent with the morphology of the precursor polyphosphazene nanotubes. After carbonization at the highest temperature of 900℃, the specific surface area of the material reaches 788.3m 2 / g, the porosity is 0.590cm 3 / g, the pore size distribution is narrow, and the pore size is about 4nm.

[0048] The electrochemical analysis of the material shows that the specific capacity of the material obtained by carbonization at 900 °C reaches 160 F / g at a scan rate of 2 mv / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com