Cobalt sulfide/g-C3N4 composite electrode material with two-dimensional hollow nano sheet structure and preparation method thereof

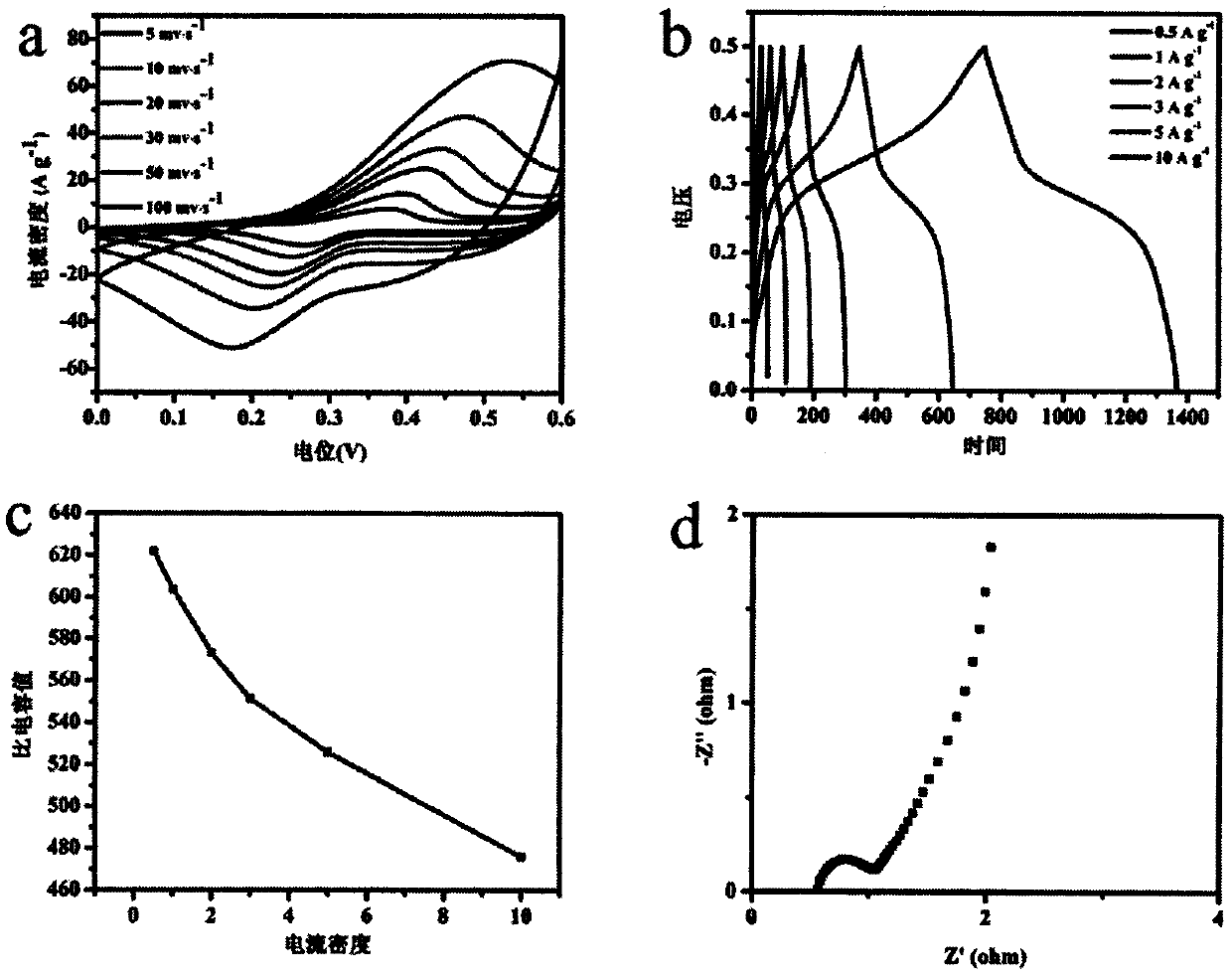

A composite electrode, g-c3n4 technology, applied in the field of supercapacitors and nanomaterials, can solve the problems of slow electrochemical reaction rate, poor cycle stability, poor conductivity, etc., and achieve good redox peaks, structural integrity, and improved conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The present invention provides cobalt sulfide / g-C with two-dimensional hollow nanosheet structure 3 N 4 The preparation method of composite electrode material comprises the following steps:

[0028] (1) One or more of melamine, thiourea, and urea are placed in a tube furnace and calcined under a nitrogen atmosphere to obtain g-C 3 N 4 ;

[0029] (2) put g-C 3 N 4 mixed with a solvent for ultrasonic dispersion, and then added C 4 h 6 N 2 Continue ultrasonic dispersion to obtain a uniform solution;

[0030] (3) mixing the cobalt salt with a solvent to obtain a uniform solution;

[0031] (4) Mix the two homogeneous solutions obtained in the steps (2), (3), stir, let stand for a period of time, centrifuge, wash, and dry to obtain the cobalt sulfide / g-C of the two-dimensional hollow nanosheet structure 3 N 4 Precursors of composite electrode materials;

[0032] (5) Put the precursor obtained in the step (4) into a solution containing a sulfur source, perform a hy...

Embodiment 1

[0041] Take 7 g of melamine and place it in a tube furnace under nitrogen atmosphere at 10 °C min -1 The heating rate was increased to 600 ° C for 2 h to obtain g-C 3 N 4 . Take 10mg g-C 3 N 4 Sonicate in 40ml water for 1h, add 1.31g C 4 h 6 N 2 Continue ultrasonic treatment for 1h, take 0.58g Co(NO 3 ) 2 ·6H 2 O is dissolved in 40ml of water; the above two solutions are mixed, wherein cobalt salt, C 4 h 6 N 2 , The mass ratio of water is: 1:2.26:138. At a stirring speed of 450rpm, stir for 5min, stand at 25°C for 4h, then centrifuge at 7000rpm for 4min, wash with deionized water and absolute ethanol three times, and dry the obtained product in a drying oven at 60°C 24h, the precursor of the composite electrode material was obtained, and its scanning electron microscope picture is as follows figure 1 as shown in a.

[0042] Add the precursor obtained in the above steps to an ethanol solution containing 3g / L thioacetamide, add the reaction solution to the lining ...

Embodiment 2

[0045] Take 7 g of melamine and place it in a tube furnace under nitrogen atmosphere at 10 °C min -1 The heating rate was increased to 500 ° C for 4 h to obtain g-C 3 N 4 . Take 20mg g-C 3 N 4 Ultrasonic dispersion in 40mL of methanol for 0.5h, take 1.31g C 4 h 6 N 2 Add to the above solution and continue to sonicate for 1h, and dissolve another 0.35g of cobalt acetate in 40mL of methanol; mix the above two solutions, in which cobalt salt, C 4 h 6 N 2 , The mass ratio of solvent is: 1: 3.7: 180.6. At a stirring speed of 250rpm, stir for 30min, stand at 25°C for 24h, centrifuge at 8000rpm for 5min, wash with deionized water and methanol three times respectively, and dry the obtained product in a drying oven at 60°C for 24h to obtain a composite electrode material precursors.

[0046] Add the precursor obtained in the above steps to an ethanol solution containing 4g / L sodium sulfide, add the reaction solution to the lining of a polytetrafluoroethylene reactor, place i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com