Preparation method and application of MXene derivative/metal nano composite material

A metal nano-composite material technology, applied in the manufacture of hybrid/electric double-layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of difficult to support interlayer structure, application limitations, impact on electrode performance, etc., to increase the number of redox centers, Increased storage capacity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

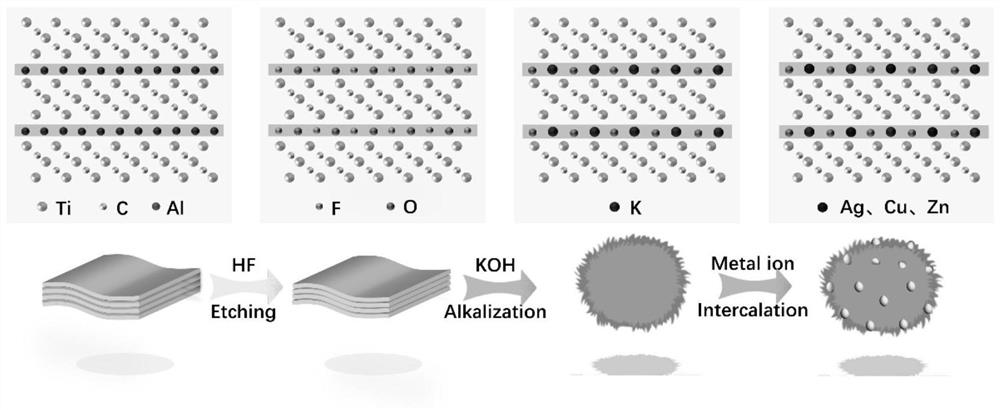

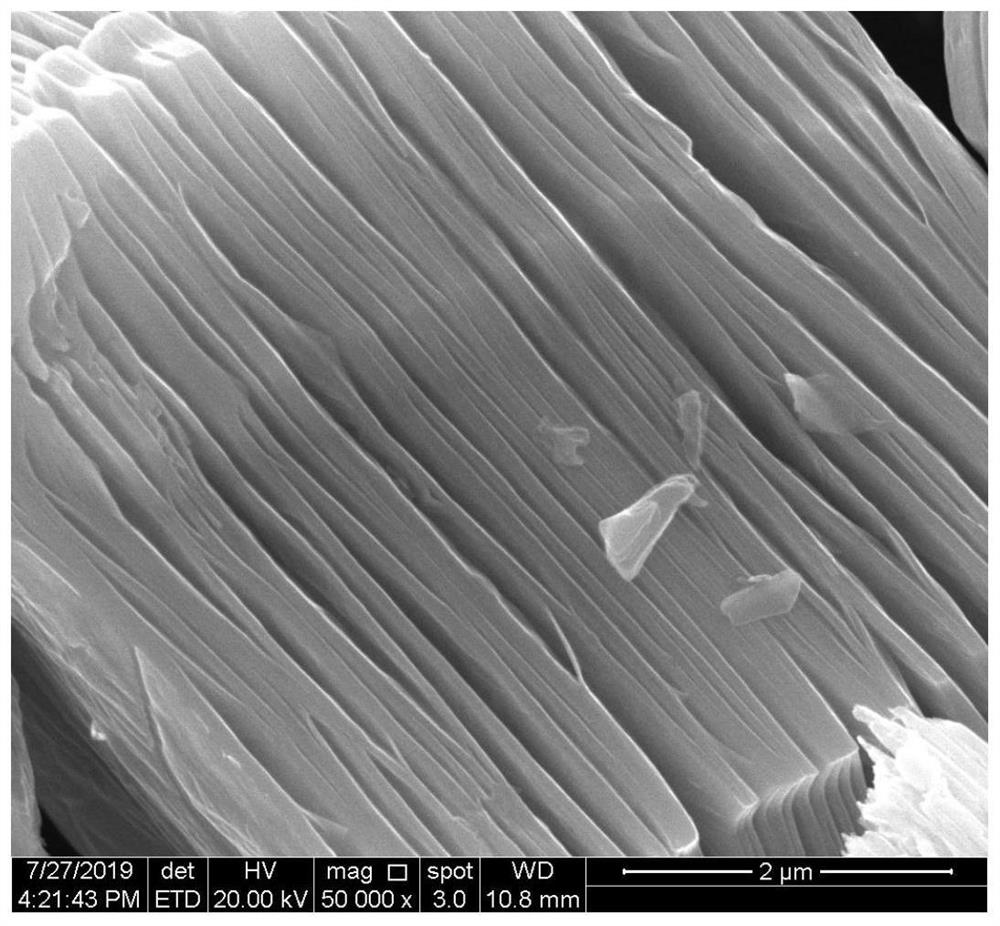

Method used

Image

Examples

Embodiment 1

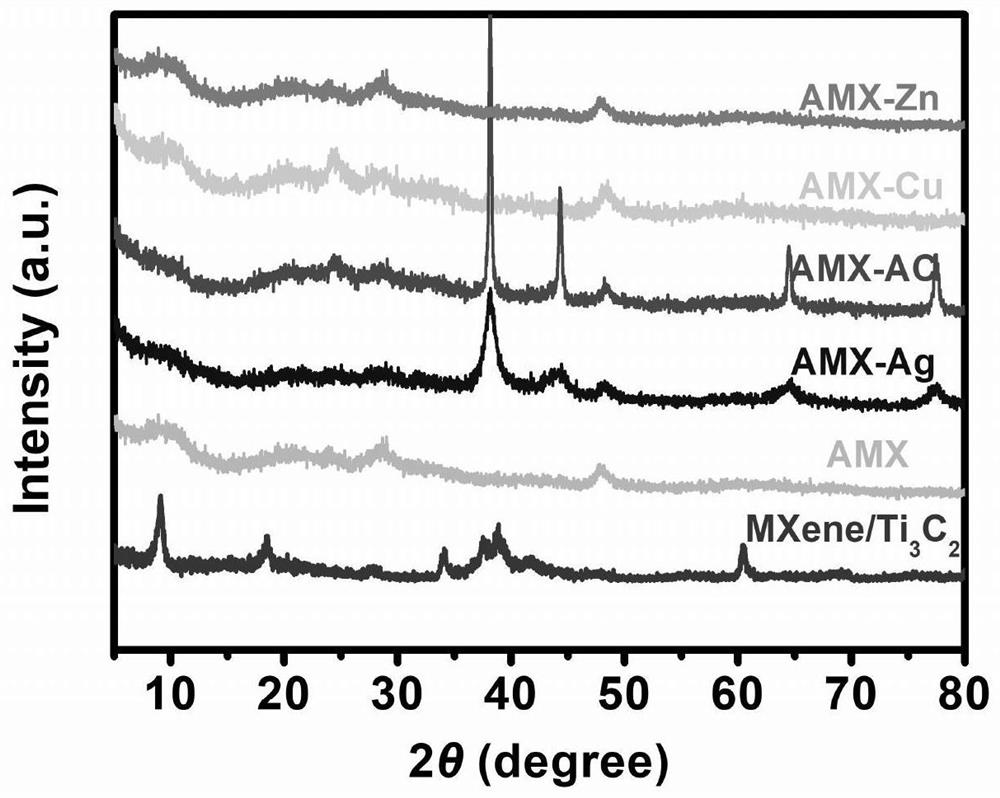

[0038] The preparation method of the MXene derivative / metal composite material (AMX-Zn) of the present embodiment is as follows:

[0039] (1) First add 200 mg MXene Ti 3 C 2 Disperse in 60 mL 1M KOH solution, add 1.36 mL H 2 o 2 (30%, AR) magnetically stirred for 1 h.

[0040] (2) Transfer the mixed solution in step (1) to an autoclave, and conduct a hydrothermal reaction at 140 °C for 12 h.

[0041] (3) Wash the product in step (2) with deionized water until the pH of the supernatant becomes neutral,

[0042] (4) Finally, the sample was dried in a vacuum drying oven at 60 °C for 12 hours to obtain a three-dimensional structure of MXene derivatives, that is, hairy spherical alkalized MXene (AMX).

[0043] (5) Mix 200 mg AMX powder, 0.3 mmol ZnCl 2 and 60 mg of polyvinylpyrrolidone k-30 were dispersed in 40 mL of ethylene glycol, and magnetically stirred for 2 h under simulated sunlight.

[0044] (6) Transfer the mixed solution in step (5) to an autoclave, and heat it at...

Embodiment 2

[0047] The preparation method of the MXene derivative / metal composite material (AMX-Ag) of the present embodiment is as follows:

[0048] (1) First add 200 mg MXene Ti 3 C 2 Disperse in 60 mL 1M KOH solution, add 1.36 mL H 2 o 2 (30%, AR) magnetically stirred for 1 h.

[0049] (2) Transfer the mixed solution in step (1) to an autoclave, and conduct a hydrothermal reaction at 140 °C for 12 h.

[0050] (3) Wash the product in step (2) with deionized water until the pH of the supernatant becomes neutral,

[0051](4) Finally, the sample was dried in a vacuum oven at 60 °C for 12 hours to obtain a three-dimensional structure of the hairy spherical alkalized MXene (AMX).

[0052] (5) Mix 200 mg AMX powder, 0.3 mmol AgNO 3 and 60 mg of polyvinylpyrrolidone k-30 were dispersed in 40 mL of ethylene glycol, and magnetically stirred for 2 h under simulated sunlight.

[0053] (6) Transfer the mixed solution in step (5) to an autoclave, and heat it at 160° C. for 3 hours.

[0054] ...

Embodiment 3

[0056] The preparation method of the MXene derivative / metal composite material (AMX-Cu) of the present embodiment is as follows:

[0057] (1) First add 200 mg MXene Ti 3 C 2 Disperse in 60 mL 1M KOH solution, add 1.36 mL H 2 o 2 (30%, AR) magnetically stirred for 1 h.

[0058] (2) Transfer the mixed solution in step (1) to an autoclave, and conduct a hydrothermal reaction at 140 °C for 12 h.

[0059] (3) Wash the product in step (2) with deionized water until the pH of the supernatant becomes neutral,

[0060] (4) Finally, the sample was dried in a vacuum oven at 60 °C for 12 hours to obtain a three-dimensional structure of the hairy spherical alkalized MXene (AMX).

[0061] (5) 200 mg AMX powder, 0.3 mmol Cu(NO 3 ) 2 and 60mg of polyvinylpyrrolidone k-30 were dispersed in 40mL of ethylene glycol, and magnetically stirred for 2h under simulated sunlight.

[0062] (6) Transfer the mixed solution in step (5) to an autoclave, and heat it at 160° C. for 3 hours.

[0063] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com