NiCo2S4/XS (X=Ni, Co) composite nanometer material and preparation method and application thereof

A composite nanomaterial, CO2 technology, applied in the field of pseudocapacitive materials and preparation, can solve the problems of large environmental pollution, high price, scarcity of sources, etc., and achieve the effects of low price, increased contact area, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In the first step, immerse the previously washed foamed nickel (1×1cm) in the uniformly mixed Ni 2+ 、Co 2+ , 80ml solution of urea (0.833g NiCl 2 ·6H 2 O, 0.357g CoCl 2 ·6H 2 (0, 0.910g urea), hydrothermal reaction at 130°C for 5 hours. Wash the nickel foam with the precursor, and dry it in a vacuum oven at 60°C.

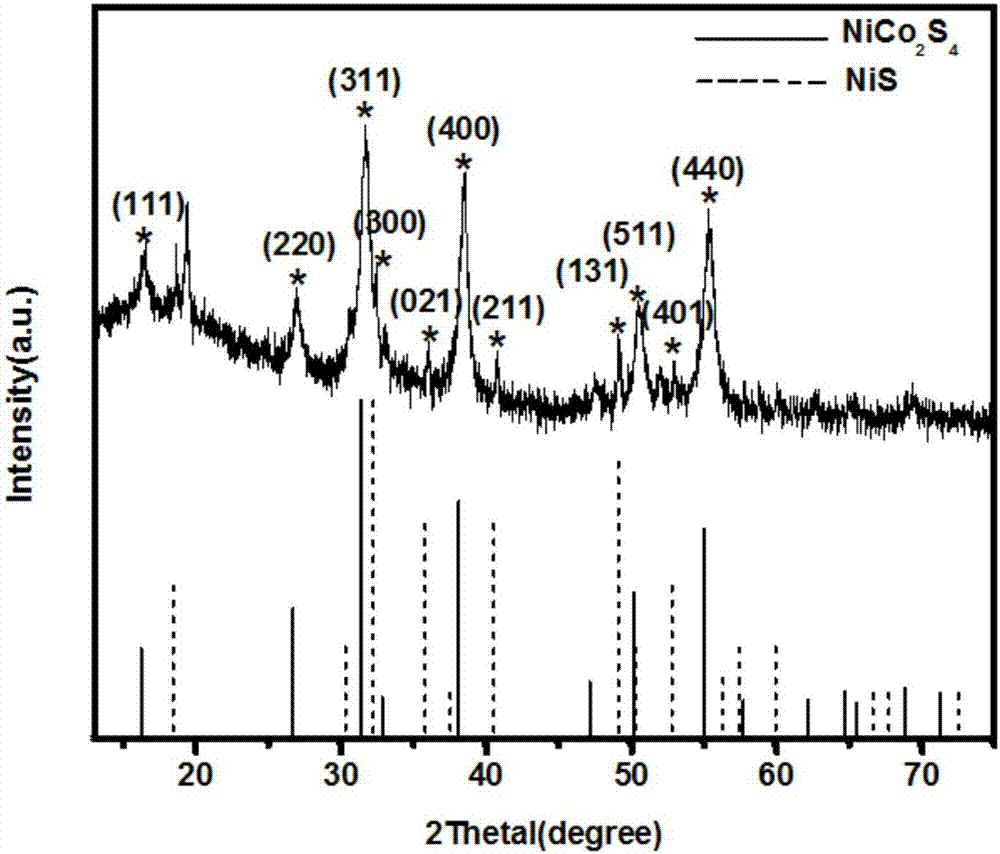

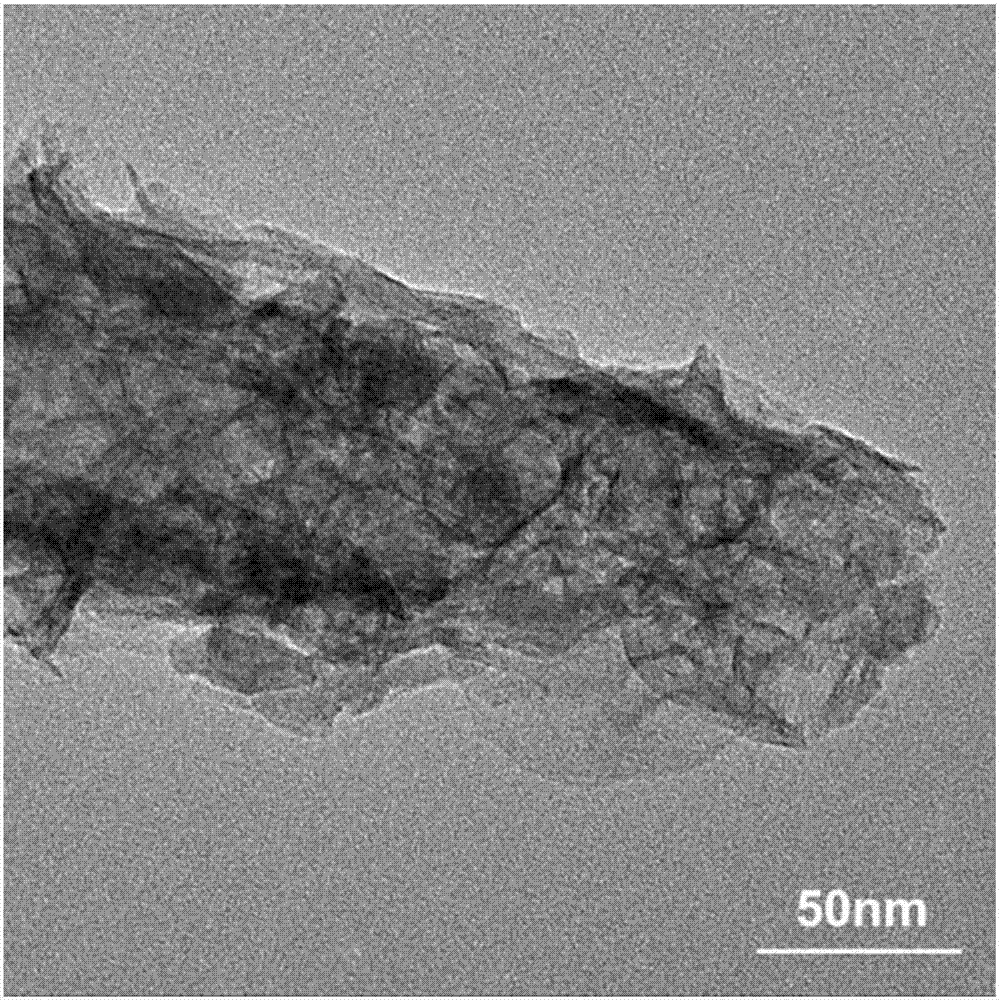

[0027] In the second step, immerse the nickel foam with the precursor in 0.1M Na 2 In the S solution, first soak at 60°C for 5 hours; then, heat at 140°C for 5 hours. Wash and dry in a vacuum oven at 60°C to obtain NiCo 2 S 4 / NiS composite nanomaterials, refer to Figure 1 to Figure 2 .

Embodiment 2

[0029] In the first step, immerse the previously washed foamed nickel (1×1cm) in the uniformly mixed Ni 2+ 、Co 2+ , 80ml solution of urea (0.238g NiCl 2 ·6H 2 O, 1.190g CoCl 2 ·6H 2 (0, 0.910g urea), hydrothermal reaction at 130°C for 5 hours. Wash the nickel foam with the precursor, and dry it in a vacuum oven at 60°C.

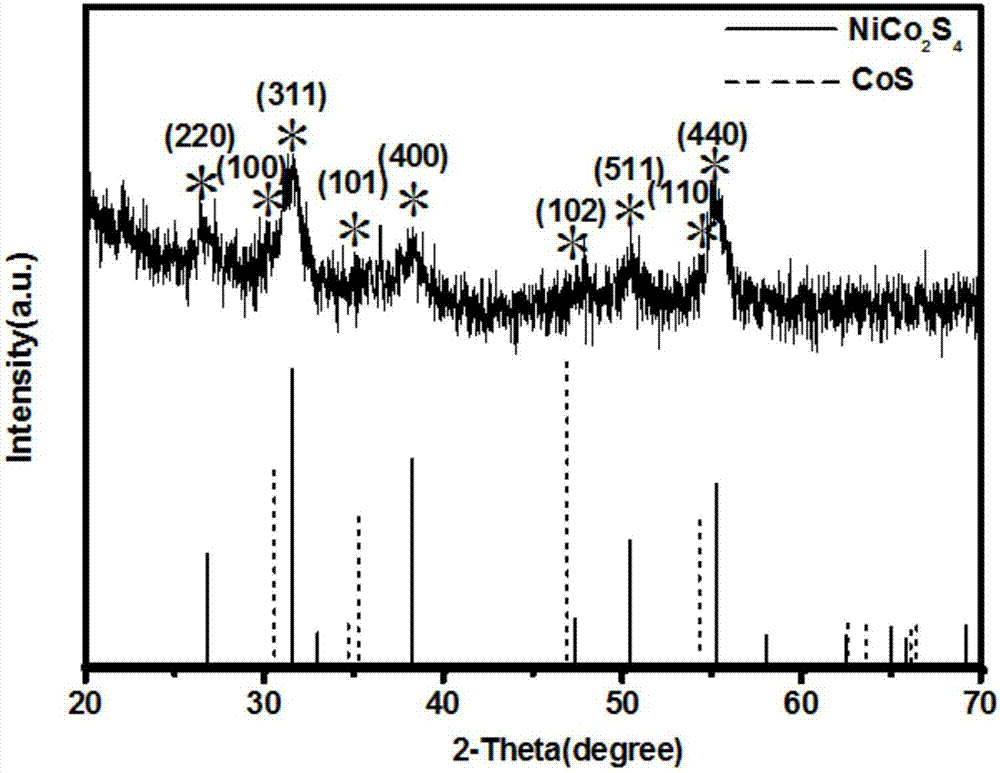

[0030] In the second step, immerse the nickel foam with the precursor in 0.1M Na 2 In the S solution, first soak at 60°C for 5 hours; then, heat at 140°C for 5 hours. Wash and dry in a vacuum oven at 60°C to obtain NiCo 2 S 4 / CoS composite nanomaterials, ref. image 3 and Figure 4 .

Embodiment 3

[0032] Loaded NiCo prepared in Example 1 2 S 4 The nickel foam sheet of / NiS composite nanomaterial is used as the working electrode, and the Pt electrode and the Hg / HgO electrode are used as the counter electrode and reference electrode respectively to form a three-electrode system for electrochemical performance testing. Figure 5 for its discharge curve. It can be seen from the figure that the current density is 3mA cm -2 Lower mass specific capacitance 1947.5F g -1 ; at a current density of 10mAcm -2After charging and discharging 1000 times, it can still maintain 90% of the capacitance, reflecting a high specific capacitance and good cycle stability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com