Pulley assembly and crane

A technology of pulley components and cranes, which is applied in the direction of load hanging components, transportation and packaging, etc., which can solve the problems of flexible cables that cannot be used normally, and achieve the effects of reducing labor intensity and avoiding danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0042] The inventor found through research that when using a pulley assembly that only uses flexible cables to connect the fixed pulley and the movable pulley, it is difficult to limit the horizontal position of the movable pulley and the hook in the horizontal direction, and the hook is easy to swing during the movement, so that it cannot be accurately moved to the desired position. Location. Especially when using in windy weather, this deficiency is particularly prominent. In order to move the hook and the movable pulley to the required position, the operator has to manually move the hook to the required position, which is not only labor-intensive, but also dangerous. During use, the cable is easy to be entangled and affects normal use.

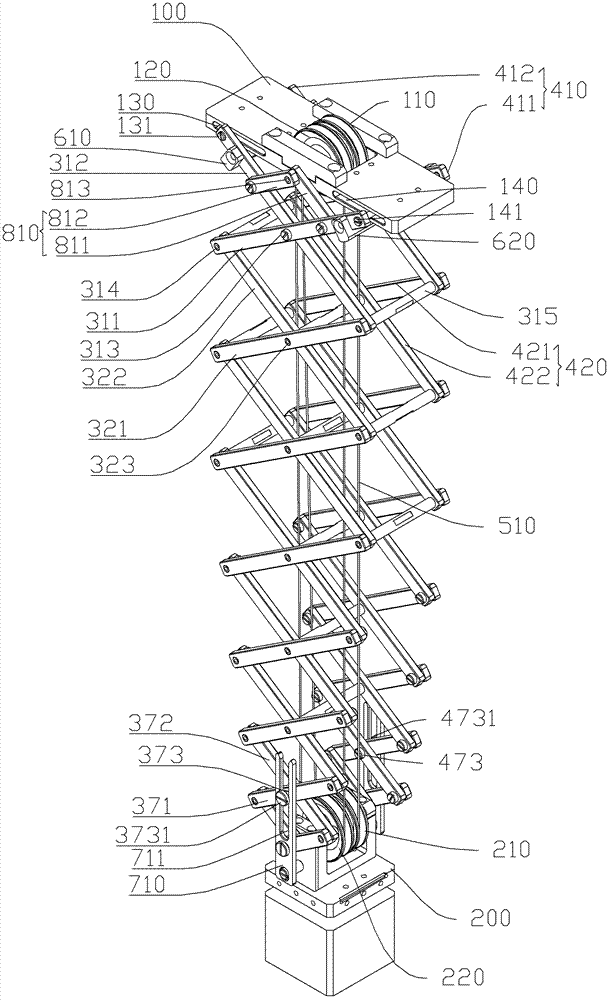

[0043] In order to solve the problem of swinging of the movable pulley and the hook, the inventor used a rigid connector to connect the first pulley bracket and the second pulley bracket after research; in order to adapt to the fact that t...

Embodiment 1

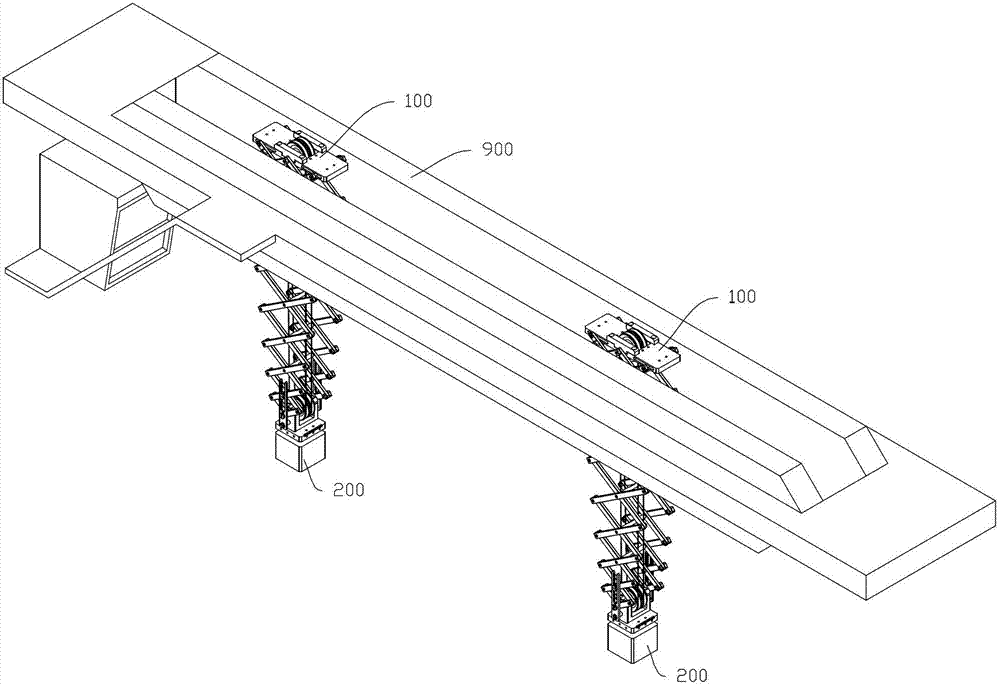

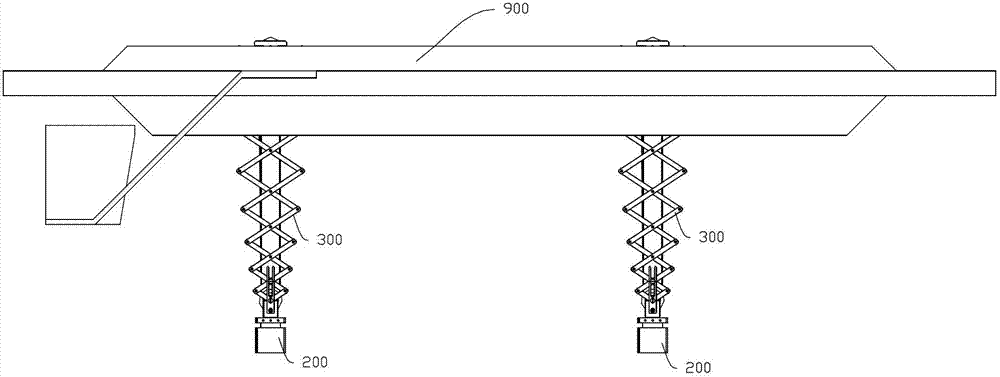

[0047] figure 1 It is a structural schematic diagram of Embodiment 1 of the present invention. figure 2 It is a schematic front view of Embodiment 1 of the present invention. image 3 It is a schematic side view of Embodiment 1 of the present invention. Such as figure 1 , figure 2 as shown, image 3 As shown, the pulley assembly includes a first pulley bracket 100 and a second pulley bracket 200 . Two rotatable fixed pulleys are arranged on the first pulley support 100 , that is, a first fixed pulley 110 and a second fixed pulley 120 . The second pulley bracket 200 is provided with two rotatable movable pulleys, that is, a first movable pulley 210 and a second movable pulley 220 . The first fixed pulley 110 and the first movable pulley 210 are a first pulley block. One end of the first flexible cable 510 is fixed on the first fixed pulley 110 , and the other end successively goes around the first movable pulley 210 , the second fixed pulley 120 and the second movable pu...

Embodiment 2

[0062] Figure 5 It is a schematic diagram of the application structure of Embodiment 2 of the present invention. Fig. 6 is a front view of Embodiment 2 of the present invention. Such as Figure 5 As shown in FIG. 6 , the gantry crane includes a beam 900 . The two first pulley brackets 100 are arranged on the beam 900 so as to be movable along the beam. A hook (not shown in the figure) is installed on the second pulley bracket 200 for hooking objects.

[0063] The usage method of the present invention is as follows: the first pulley bracket 100 first moves along the beam 900 to a required position in the horizontal direction. The winding device works to wind the first flexible cable 510, and uses the first flexible cable 510 to pull the first movable pulley 210 and the second movable pulley 220 upwards, so that the first movable pulley 210, the second movable pulley 220 and the second pulley bracket 200 can move upward and approach The first pulley bracket 100. When the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com