Preparation method of nitrogen, phosphorus, and sulfur ternary co-doped ordered mesoporous carbon material

A technology of co-doping and mesoporous carbon, which is applied in the manufacture of hybrid/electric double layer capacitors and electrodes of hybrid capacitors, etc., can solve the problem of limited improvement in the capacitance performance of mesoporous carbon materials, and achieve the effect of improving capacitance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

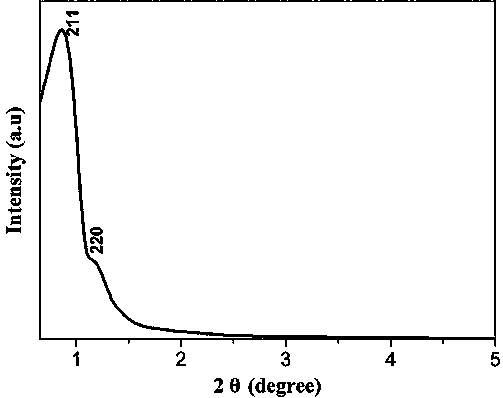

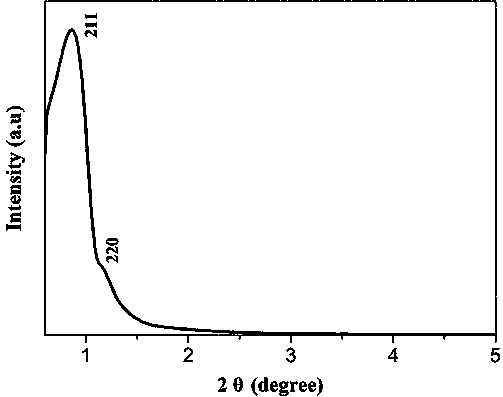

[0025] Specific Embodiment 1: In this embodiment, the preparation method of nitrogen, phosphorus, and sulfur ternary co-doped ordered mesoporous carbon materials is implemented according to the following steps:

[0026] 1. Synthesis of ordered mesoporous silica template (KIT-6) by hydrothermal synthesis method;

[0027] 2. (1) Dry KIT-6 is ultrasonically treated in deionized water to obtain a uniform dispersion; at the same time, add sucrose, phosphoric acid and thiosemicarbazide to deionized water and stir to obtain a uniform solution, and the mass ratio, m(KIT -6): m (sucrose): m (phosphoric acid): m (thiosemicarbazide) = 8: 8: (2~1): (2~1). (2) Transfer the latter to the former and continue stirring for 12 h at 40 °C in a fume hood. (3) Place the obtained paste compound in an oven to dry at 80°C for 12 hours, and then grind the dried solid into powder. (4) Pyrolyze the composite powder in a tube furnace at 800 °C for 2 h under high-purity nitrogen (50 ml / s), with a heatin...

specific Embodiment approach 2

[0029] Embodiment 2: This embodiment differs from Embodiment 1 to Embodiment 4 in that the pyrolysis temperature in Step 2 is 700° C., and other steps and parameters are the same as Embodiment 1 to Embodiment 4.

specific Embodiment approach 3

[0030] Embodiment 3: This embodiment differs from Embodiment 1 to Embodiment 1 in that the pyrolysis temperature in Step 2 is 900° C., and other steps and parameters are the same as Embodiment 1 to Embodiment 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com