A kind of nickel cobalt oxide graphene composite material and its application and preparation method

A composite material and graphene technology, applied in capacitors, circuits, electrolytic capacitors, etc., can solve the problems of large particle size and poor conductivity of nickel cobaltate, and achieve the effects of small size, improved capacitance performance, and easy large-scale production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Preparation of graphite oxide. Graphite oxide is prepared by oxidizing graphite with strong oxidants such as nitric acid and sulfuric acid;

[0030] (2) Take 0.3g graphite oxide and add 100mL deionized water to ultrasonic for 2.5h to prepare graphene oxide solution;

[0031] (3) Add 10ml 0.002mol / L cobalt chloride aqueous solution and 10mL 0.001mol / L nickel chloride aqueous solution to (2), and stir for 0.5h;

[0032] (4) Dissolve 2g of sodium hydroxide in 10mL of deionized water and stir for 1h;

[0033] (5) Mix and stir the system obtained in (3) and (4) for 2 hours, then transfer to a high-temperature reactor, and react at 160°C for 12 hours;

[0034] (6) The product obtained in (5) was filtered, washed, vacuum-dried at 60°C for 18 hours, and then heat-treated in a tube furnace at 350°C for 3 hours to obtain a nickel cobaltate nanowire-graphene composite material.

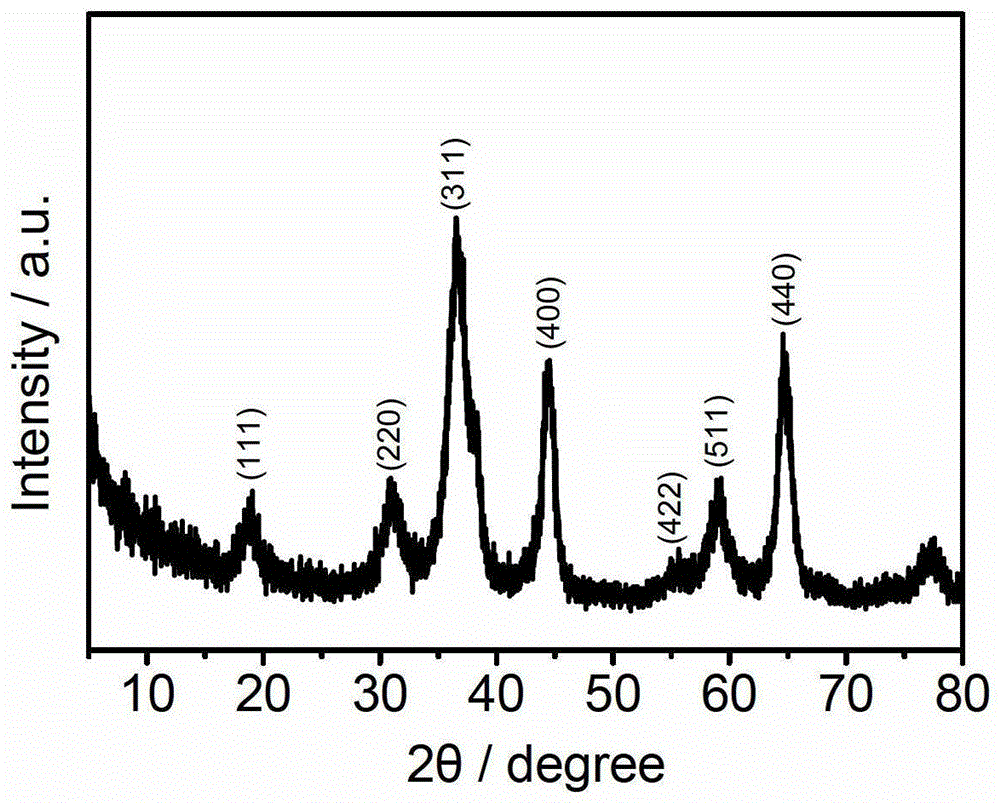

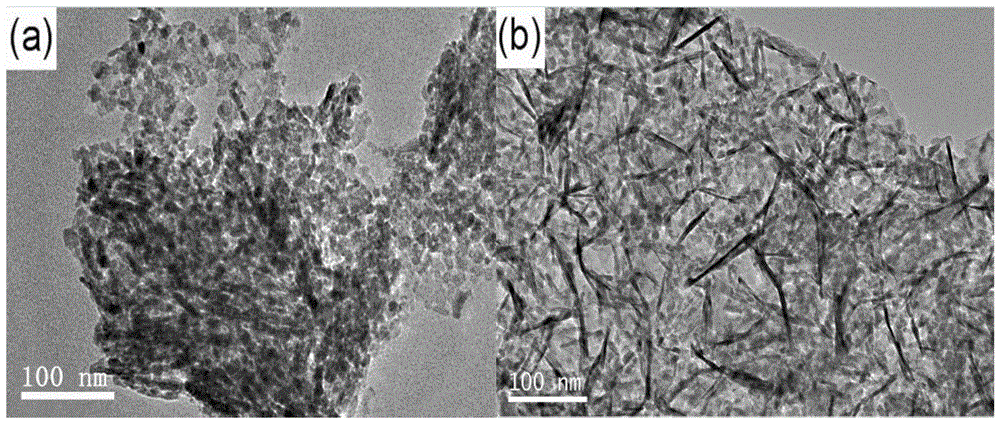

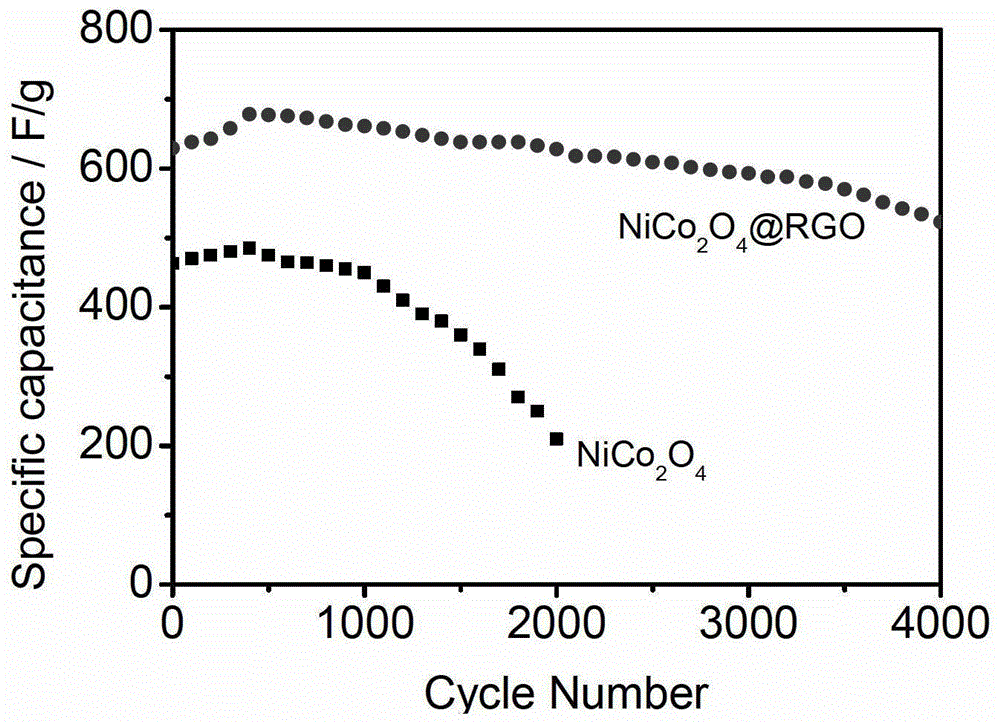

[0035] figure 1 It is the X-ray diffraction (XRD) pattern of the obtained nickel cobaltate nan...

Embodiment 2

[0037] (1) Same as Step 1 in Example 1;

[0038] (2) Take 0.5g graphite oxide and add 100mL deionized water to ultrasonic for 2h to prepare graphene oxide solution;

[0039] (3) Add 10ml 0.002mol / L cobalt nitrate aqueous solution and 10mL 0.001mol / L nickel nitrate aqueous solution to (2), and stir for 0.5h;

[0040] (4) Dissolve 5g of ammonium bicarbonate in 10mL of deionized water and stir for 1h;

[0041] (5) Mix and stir the system obtained in (3) and (4) for 2 hours, then transfer to a high-temperature reactor, and react at 200°C for 8 hours;

[0042] (6) The product obtained in (5) was filtered, washed, vacuum-dried at 80°C for 12 hours, and then heat-treated in a tube furnace at 500°C for 2 hours to obtain a nickel cobaltate nanowire-graphene composite material.

[0043] Characterized by XRD, the obtained product is nickel cobaltate with spinel structure (JCPDS 20-0781), without NiO and Co 3 o 4 impurity peaks. In the transmission electron microscope (TEM) photo, th...

Embodiment 3

[0045] (1) Same as Step 1 in Example 1;

[0046] (2) Take 0.1g graphite oxide and add 100mL deionized water to ultrasonic for 0.5h to prepare graphene oxide solution;

[0047] (3) Add 20ml 0.001mol / L cobalt acetate aqueous solution and 20mL 0.0005mol / L nickel acetate aqueous solution to (2), stir for 1h;

[0048] (4) Dissolve 10g of sodium carbonate in 10mL of deionized water and stir for 1 hour;

[0049] (5) Mix and stir the system obtained in (3) and (4) for 2 hours, then transfer to a high-temperature reactor, and react at 120°C for 24 hours;

[0050] (6) The product obtained in (5) was filtered, washed, vacuum-dried at 100°C for 10 hours, and then heat-treated in a tube furnace at 200°C for 6 hours to obtain a nickel cobaltate nanowire-graphene composite material.

[0051] Characterized by XRD, the obtained product is nickel cobaltate with spinel structure (JCPDS 20-0781), without NiO and Co 3 o 4 impurity peaks. In the transmission electron microscope (TEM) photo, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com