Preparation method of N-doped carbon nanotube/nickel cobalt oxide/N-doped porous carbon

A technology of cobalt nickel oxide and carbon nanotubes, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of coke demand decline, environmental pollution, etc., and achieve the improvement of capacitance performance and conductivity Excellent performance, improved wetting characteristics and electrochemical activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

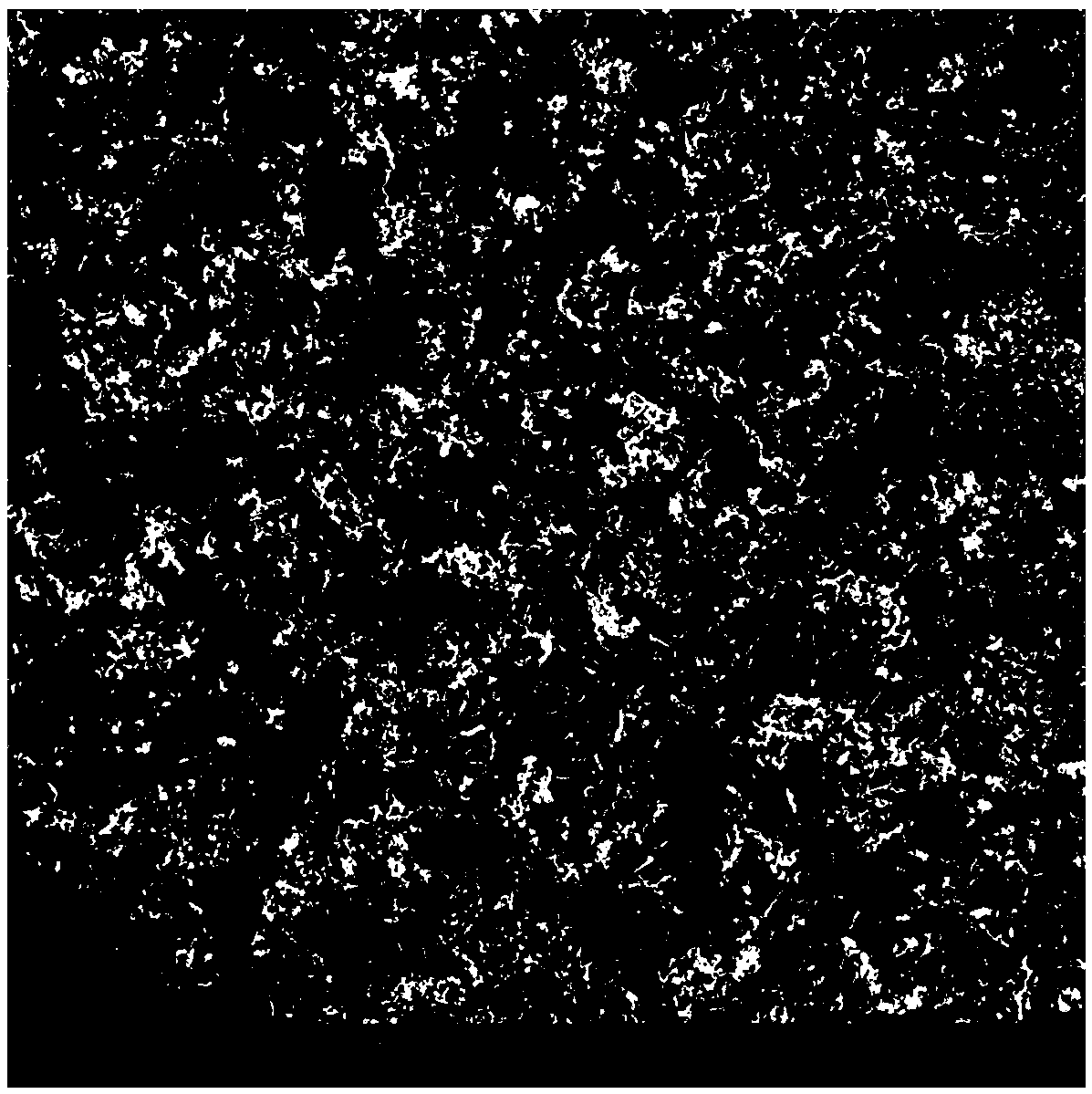

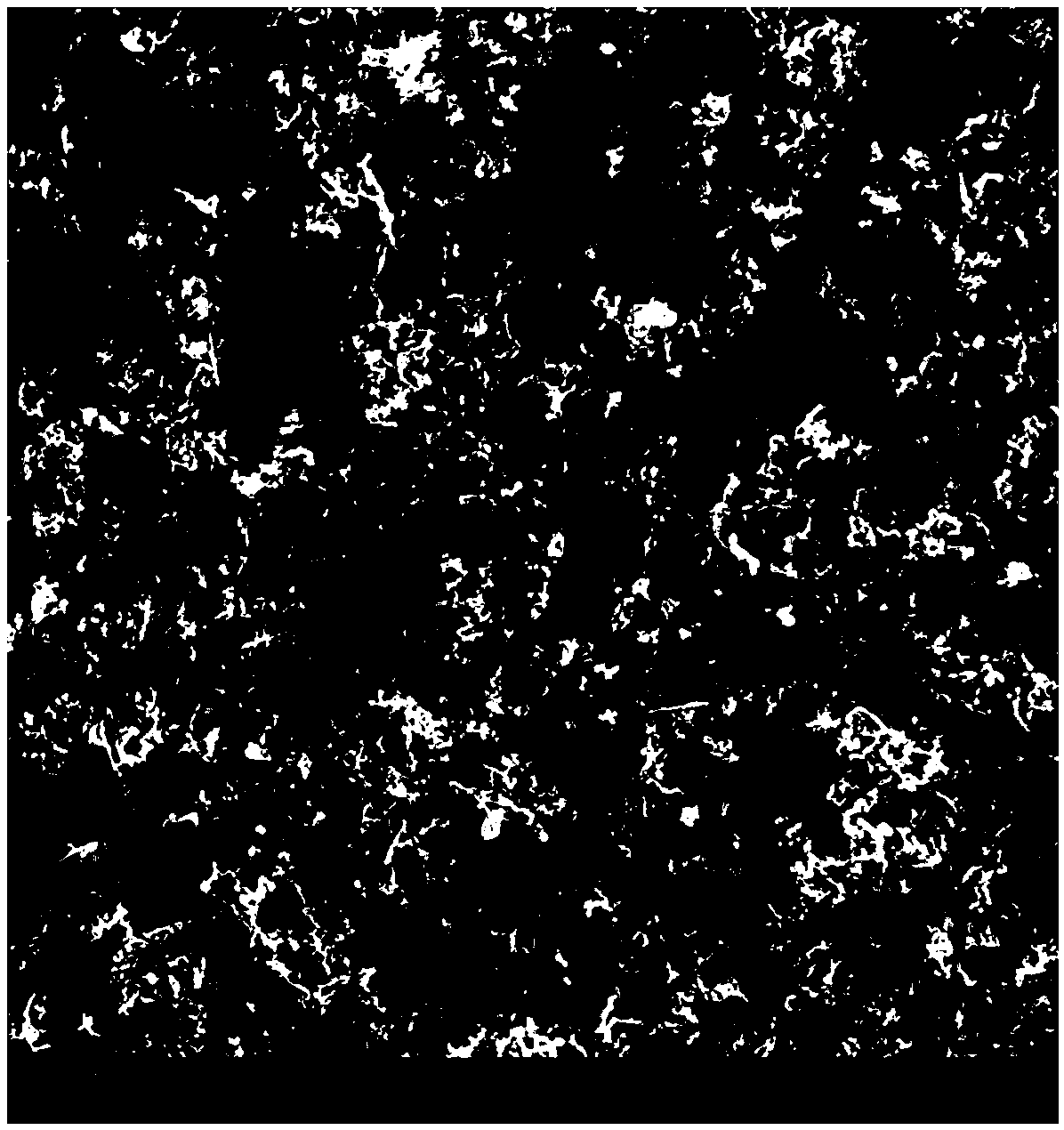

Image

Examples

Embodiment 1

[0052] The coal-based polyaniline used in this example was prepared by in-situ polymerization according to the preparation method of coal-based polyaniline disclosed in "A N-doped Porous Carbon / NiO Composite Material and Its Preparation Method" in Patent No. 201510464778.2, specifically for:

[0053] Step 101, uniformly mix 10 g of aniline, 30 mL of concentrated hydrochloric acid (37% in mass concentration) and 60 mL of water to obtain a mixed solution, add 10 g of coal powder to the mixed solution, stir and swell at 35° C. for 3 h to obtain a swollen coal sample;

[0054] Step 102. Add 80 mL of ammonium persulfate aqueous solution with a concentration of 0.30 g / mL dropwise to the swollen coal sample described in step 101 under stirring in an ice-water bath at 1° C. at a rate of 2 mL / min. After the addition is complete, Continue to stir for 8 hours under the condition of an ice-water bath at 1°C, filter with suction, wash the filter cake obtained by suction filtration, then va...

Embodiment 2

[0067] The coal-based polyaniline used in this example was prepared by in-situ polymerization according to the preparation method of coal-based polyaniline disclosed in "A N-doped Porous Carbon / NiO Composite Material and Its Preparation Method" in Patent No. 201510464778.2, specifically for:

[0068] Step 101, uniformly mix 10 g of aniline, 30 mL of concentrated hydrochloric acid (37% in mass concentration) and 60 mL of water to obtain a mixed solution, add 10 g of coal powder to the mixed solution, stir and swell at 30° C. for 3 h to obtain a swollen coal sample;

[0069] Step 102. Add 80 mL of ammonium persulfate aqueous solution with a concentration of 0.30 g / mL dropwise to the swollen coal sample described in step 101 in a 3° C. ice-water bath with stirring at a rate of 2 mL / min. After the dropwise addition is completed, Continue to stir for 7 hours under the condition of an ice-water bath at 3°C, filter with suction, wash the filter cake obtained by suction filtration, th...

Embodiment 3

[0081] The coal-based polyaniline used in this example was prepared by in-situ polymerization according to the preparation method of coal-based polyaniline disclosed in "A N-doped Porous Carbon / NiO Composite Material and Its Preparation Method" in Patent No. 201510464778.2, specifically for:

[0082] Step 101, uniformly mix 10 g of aniline, 30 mL of concentrated hydrochloric acid (37% in mass concentration) and 60 mL of water to obtain a mixed solution, add 10 g of coal powder to the mixed solution, stir and swell at 25° C. for 3 h to obtain a swollen coal sample;

[0083] Step 102. Add 80 mL of ammonium persulfate aqueous solution with a concentration of 0.30 g / mL dropwise to the swollen coal sample described in step 101 under agitation in an ice-water bath at 5° C. at a rate of 2 mL / min. After the dropwise addition is completed, Continue to stir for 6 hours under the condition of ice-water bath at 5°C, filter with suction, wash the filter cake obtained by suction filtration,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com