Preparation method for ferric oxide/carbon nanotube composite electrode material based on microwave irradiation

A carbon nanotube composite and carbon nanotube technology, applied in the direction of hybrid capacitor electrodes, can solve the problems of environmental pollution, high cost, and long time required, and achieve the effects of reducing pollution, improving capacitance performance, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Weigh 0.1g multi-walled carbon nanotubes, 0.695g FeSO 4 •7H 2 O, placed in 5mL deionized water, ultrasonically dispersed for 10min. Add 20mL of 30% hydrogen peroxide at a dropping rate of 2mL / min, stir evenly, and reflux for 20min under microwave irradiation with a power of 500W. After cooling, wash with deionized water and filter. The filtrate was ultrasonically dispersed in 10 mL of deionized water again, and freeze-dried for 20 h to obtain a composite electrode material precursor. Under the protection of nitrogen, the composite electrode material precursor was annealed at 500° C. for 2 hours to obtain the iron oxide / carbon nanotube composite electrode material.

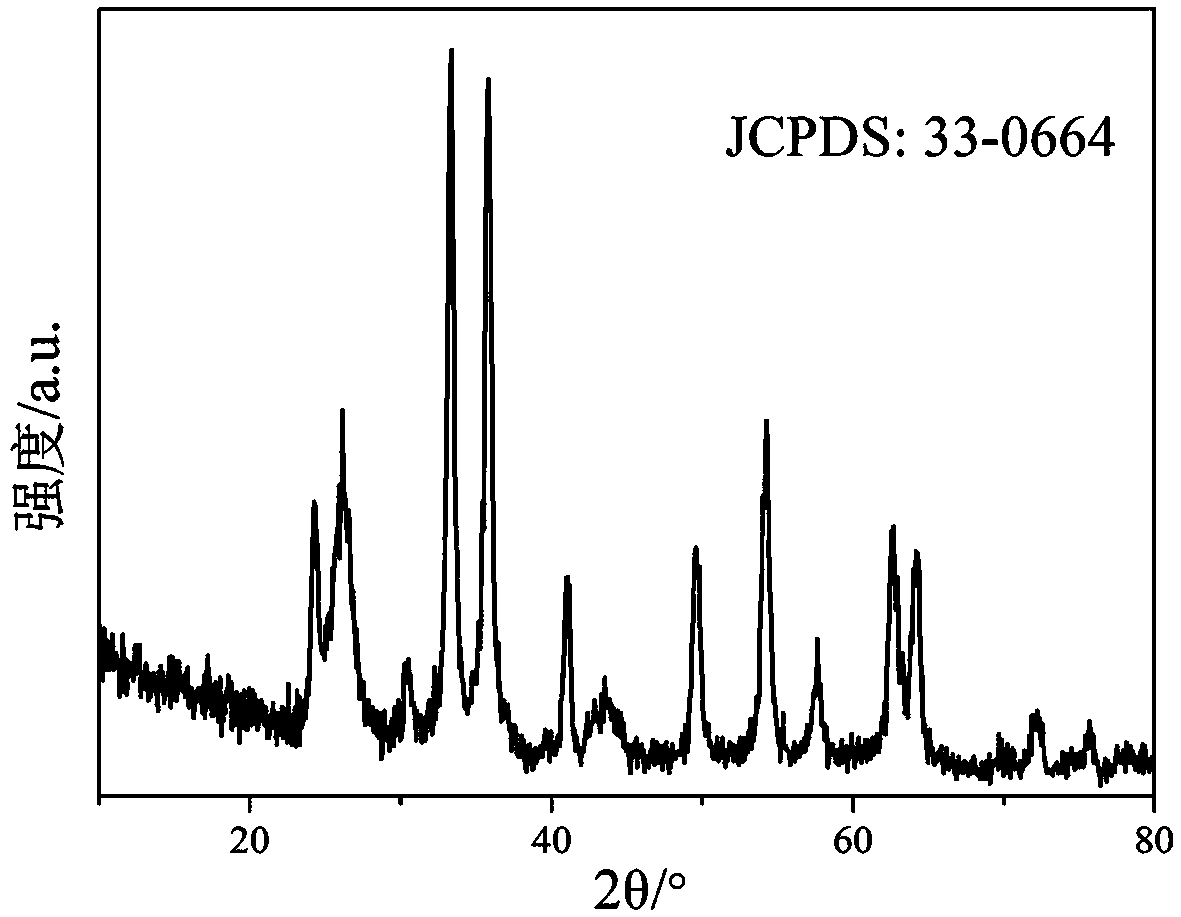

[0027] figure 1 is the XRD pattern of the composite material prepared above. Near 26° in the figure is the (002) characteristic peak of carbon nanotubes, and the remaining characteristic peaks are related to Fe 2 o 3 The PDF standard card corresponds to JCPDS: 33-00664.

[0028] figure 2 The SEM im...

Embodiment 2

[0031] Weigh 0.15g of multi-walled carbon nanotubes, 0.556g of FeSO 4 •7H 2 O, placed in 5mL deionized water, ultrasonically dispersed for 15min. Add 25mL of 30% hydrogen peroxide at a dropping rate of 4mL / min, stir evenly, and reflux for 15min under microwave irradiation with a power of 400W. After cooling, wash with deionized water and filter. The filtrate was ultrasonically dispersed in 10 mL of deionized water again, and freeze-dried for 18 h to obtain a composite electrode material precursor. Under nitrogen protection, the composite electrode material precursor was annealed at 450° C. for 2 hours to obtain an iron oxide / carbon nanotube composite electrode material.

[0032] Figure 4 The middle curve b is the charge-discharge cycle curve of the electrode composite material prepared in this embodiment. In a symmetrical supercapacitor, with 1mol / L Na 2 SO 4 It is an electrolyte solution, the voltage window is 0-1V, and the charge and discharge current density is 1A / g...

Embodiment 3

[0034] Weigh 0.05g multi-walled carbon nanotubes, 0.695g FeSO 4 •7H 2 O, placed in 5mL deionized water, ultrasonically dispersed for 10min. Add 20mL of 30% hydrogen peroxide at a rate of 2mL / min, stir evenly, and reflux for 10min under microwave irradiation with a power of 700W. After cooling, wash with deionized water and filter. The filtrate was ultrasonically dispersed in 10 mL of deionized water again, and freeze-dried for 22 h to obtain a composite electrode material precursor. Under nitrogen protection, the composite electrode material precursor was annealed at 400° C. for 3 hours to obtain an iron oxide / carbon nanotube composite electrode material.

[0035] In a symmetrical supercapacitor, with 1mol / L Na 2 SO 4 It is an electrolyte solution, the voltage window is 0-1V, and the charge and discharge current density is 1A / g. After 1000 cycles, the capacitor capacity remains at 84F / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com