Vanadium oxide and carbon composite material with hierarchical pore structure and preparation method thereof

A carbon composite material, vanadium oxide technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of high activity, phase transition, guest particle aggregation, etc., to achieve simple preparation process, capacitive performance Improved and good operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A preferred embodiment in the preparation method of vanadium oxide and carbon composite material, comprises the following steps:

[0025] Mix 1.0g hydrochloric acid solution (0.2mol / L), 1.6g block copolymer F127, 8.0g ethanol, 5.0g ethanol solution with a concentration of 20wt% phenolic resin and 1.5g ammonium metavanadate, and stir at 40°C for 2h. Transfer the mixture to a flat-bottomed evaporating dish, volatilize the ethanol at room temperature at 25°C, and form a dark brown film after about 8 hours. Put the film into a 100°C oven for thermal polymerization and keep it warm for 24 hours, and then heat it under a nitrogen atmosphere at 1°C / The heating rate of min was raised to 700°C for carbonization, and after 3 hours of heat preservation, it was naturally cooled to room temperature to obtain vanadium oxide and carbon composite materials.

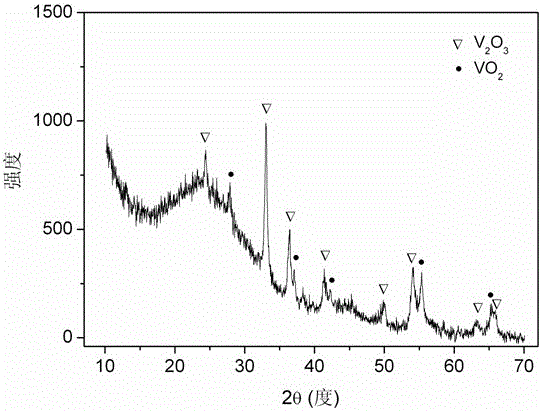

[0026] The XRD pattern of the product is shown in figure 1 , it can be seen from the figure that there is V in the composite m...

Embodiment 2

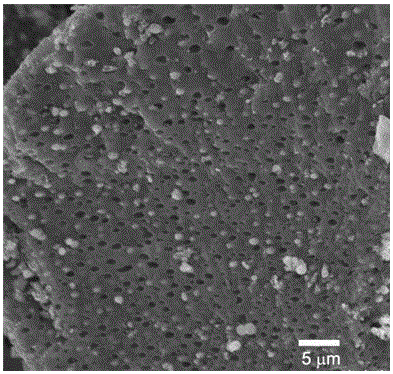

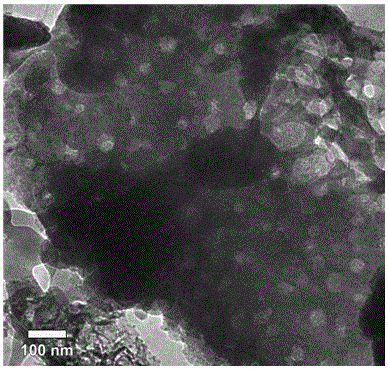

[0029] An embodiment of the preparation method of vanadium oxide and carbon composite material, the steps are the same as in Example 1, the difference is that the mass ratio of the ammonium metavanadate to the amount of hydrochloric acid is 0.5, and the ethanol is volatilized at room temperature at 25 ° C for about 8 hours Finally, a dark blue film is formed, thermally polymerized at 100°C and kept for 24 hours, then heated to 700°C for carbonization at a rate of 2°C / min under a nitrogen atmosphere, and then naturally cooled to room temperature after holding for 3 hours to obtain a vanadium oxide and carbon composite material . SEM, TEM and pore size distribution test show that the product has macropore and mesopore structure, the size of macropore is 0.4~1.5μm, and the size of mesopore is 3.5~5.4nm. XRD analysis test shows that the obtained material has V 2 o 3 and VO 2 Two phases. The specific surface area of the composite material is 413.8m 2 / g, the specific capacit...

Embodiment 3

[0031] An embodiment of the preparation method of vanadium oxide and carbon composite material, the steps are the same as in Example 1, the difference is that the mass ratio of the ammonium metavanadate to the amount of hydrochloric acid is 2.0, and the ethanol is volatilized at room temperature at 25°C for about 8h Finally, a brown-black film is formed, thermally polymerized at 100°C and kept for 24 hours, then heated to 700°C for carbonization at a rate of 1.5°C / min under nitrogen atmosphere, and then naturally cooled to room temperature after holding for 3 hours to obtain vanadium oxide and carbon. composite material. SEM, TEM and pore size distribution tests show that the product has macropore and mesopore structure, the size of macropore is 0.2~0.8μm, and the size of mesopore is 2.8~4.6nm. XRD analysis test shows that the obtained material has V 2 o 3 and VO 2 Two phases. The specific surface area of the composite material is 198.2m 2 / g, the specific capacitance is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com