Method for transferring graphene film with static protective film as medium

A graphene film and protective film technology, applied in chemical instruments and methods, electronic equipment, lamination devices, etc., can solve the problems of comparison, transfer integrity and reliability, etc., and achieve convenient use, cost saving, and easy operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

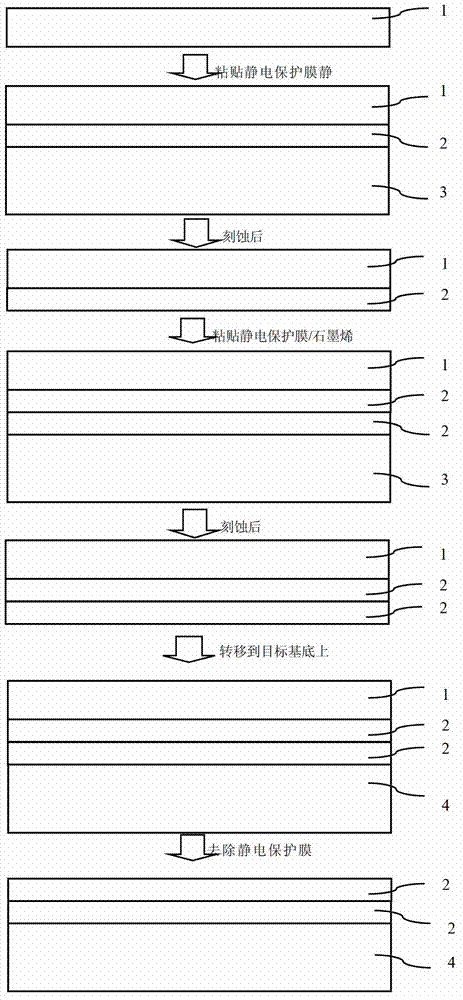

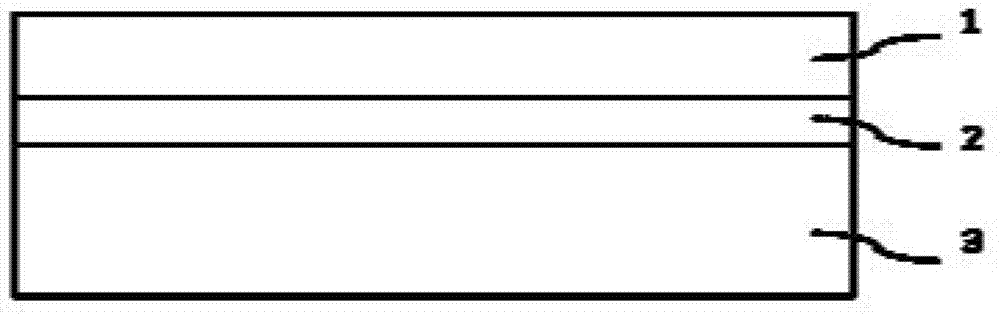

[0063] A method for transferring multilayer graphene using electrostatic protection film, comprising the following steps:

[0064] (1) Use copper foil as a substrate to prepare graphene film by vapor phase deposition method, sandwich the copper foil with graphene between two pieces of glass, and apply a certain force to make the surface of the copper foil film flat and less wrinkled; The film machine completely laminates the PP electrostatic protective film and the copper foil with graphene, the lamination speed is 10mm / min, and the lamination temperature is room temperature;

[0065] (2) Put the electrostatic protective film / copper foil with graphene combination into the ammonium persulfate solution to etch, with the side of the electrostatic protective film facing up and the side of the copper foil facing down; after 10 minutes, remove the Clean the surface of the copper foil with ionized water and ethanol, and use the same method to clean twice in a row; etch for 3 hours, a...

Embodiment 2

[0071] A method for transferring multilayer graphene using electrostatic protection film, comprising the following steps:

[0072] (1) The graphene film with copper foil as the substrate is prepared by vapor deposition method, and the copper foil with graphene is rolled through the laminating machine to make the copper foil film very flat, and the laminating speed is 200mm / min; Technology, the PET electrostatic protective film is attached to the copper foil with graphene; the lamination speed is 200mm / min, and the lamination temperature is room temperature;

[0073] (2) Put the combination of electrostatic protective film and copper foil with graphene into ferric chloride solution to etch. After 10 minutes, clean the surface of copper foil with deionized water and methanol. time; etch for 3h, and the copper foil is completely removed; then the graphene / static protective film is taken out from the ferric chloride solution, and the surface of the graphene / static protective film ...

Embodiment 3

[0079] A method for transferring multilayer graphene using electrostatic protection film, comprising the following steps:

[0080] (1) The graphene film with nickel foil as the substrate is prepared by vapor deposition method, and the copper foil with graphene is rolled through the laminating machine to make the nickel foil film very flat, and the laminating speed is 1000mm / min; Technology, attaching PVC electrostatic protective film to nickel foil with graphene; among them, the laminating speed is 1000mm / min;

[0081] (2) Etch the combination of electrostatic protective film and nickel foil with graphene in ferric nitrate solution; after 10 minutes, clean the surface of nickel foil with deionized water and methanol. times; etch for 3h, and the nickel foil is completely removed; then the graphene / static protective film is taken out from the ferric chloride solution, the surface of the graphene / static protective film is rinsed with deionized water and methanol, and dried at 60°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com