Preparation method of bromine-doped high-conductivity ultrathin graphene film

A graphene film, highly conductive technology, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of poor orientation of graphene film, poor AB stacking between layers, affecting the performance of graphene film, etc. , to increase the electron density, easy to fit, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

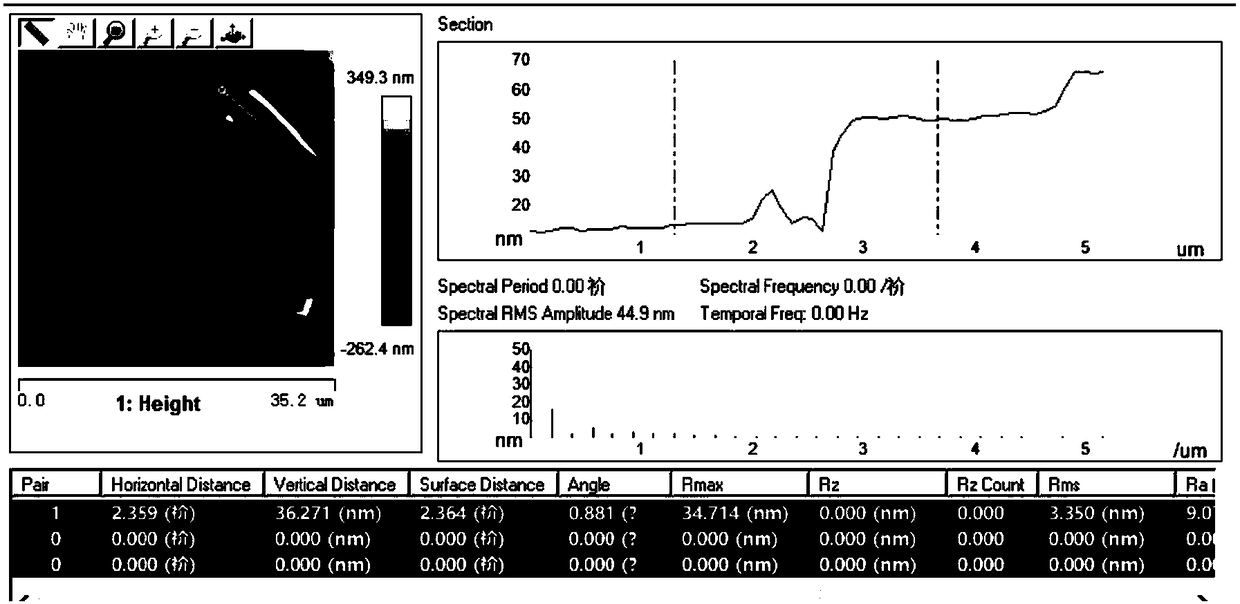

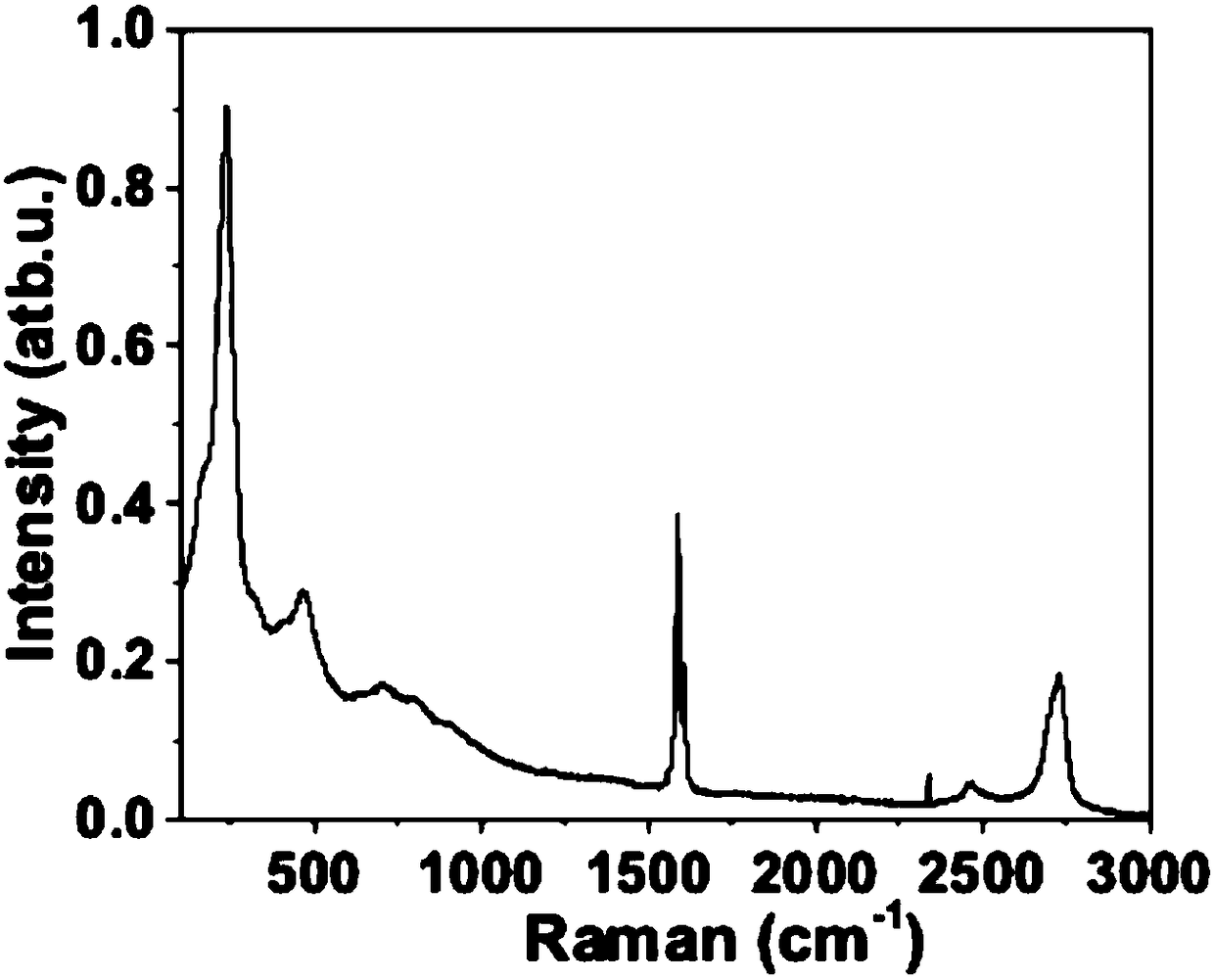

[0023] (1) Graphene oxide was prepared into a graphene oxide aqueous solution with a concentration of 0.5ug / mL, and the AAO membrane was used as the substrate to form a film by suction filtration.

[0024] (2) Place the graphene oxide film attached to the AAO in a closed container, and fumigate from the bottom to the top for 1 hour at a high temperature of 80 degrees HI.

[0025] (3) Apply the melted solid transfer agent camphor evenly on the surface of the reduced graphene oxide film by evaporation, and slowly cool it at room temperature until the basement film falls off naturally.

[0026] (4) Slowly volatilize the solid transfer agent from the graphene film supported by the solid transfer agent obtained above at 60 degrees Celsius to obtain an independent self-supporting graphene film.

[0027] (5) Place the above-mentioned independent self-supporting graphene film in a high-temperature furnace, heat up to 2000 degrees Celsius at a rate of 5 degrees Celsius per minute, and ...

Embodiment 2

[0030] A preparation method of a bromine-doped highly conductive ultra-thin graphene film, comprising the steps of:

[0031] (1) Graphene oxide was prepared into a graphene oxide aqueous solution with a concentration of 10ug / mL, and the AAO membrane was used as the substrate to form a film by suction filtration.

[0032] (2) Place the graphene oxide film attached to the AAO in a closed container, and fumigate from the bottom to the top at 100 degrees HI for 0.1 h.

[0033] (3) The melted solid transfer agent rosin was uniformly coated on the surface of the reduced graphene oxide film by casting method, and cooled naturally at room temperature until the basement film fell off naturally.

[0034] (4) volatilize the solid transfer agent from the graphene film supported by the solid transfer agent obtained above at 120 degrees to obtain an independent self-supporting graphene film.

[0035] (5) Place the above-mentioned independent self-supporting graphene film in a high-temperat...

Embodiment 3

[0038] A preparation method of a bromine-doped highly conductive ultra-thin graphene film, comprising the steps of:

[0039] (1) Graphene oxide is prepared into a graphene oxide aqueous solution with a concentration of 1 ug / mL, and the AAO membrane is used as the substrate to form a film by suction filtration.

[0040] (2) Place the graphene oxide film attached to the AAO in a closed container, and fumigate from the bottom to the top for 30 minutes at a high temperature of 100 degrees HI.

[0041] (3) The melted solid transfer agent rosin was uniformly coated on the surface of the reduced graphene oxide film by casting method, and cooled naturally at room temperature until the basement film fell off naturally.

[0042] (4) volatilize the solid transfer agent from the graphene film supported by the solid transfer agent obtained above at a temperature of 120°C to obtain an independent self-supporting graphene film.

[0043] (5) Place the above-mentioned independent self-support...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com