Single-layer graphene capable of dispersing stably and preparation method thereof

A single-layer graphene and graphene technology, which is applied in the field of single-layer graphene and its preparation, can solve problems such as the adverse effects of graphene, and achieve excellent dispersion performance, good stability, and good compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

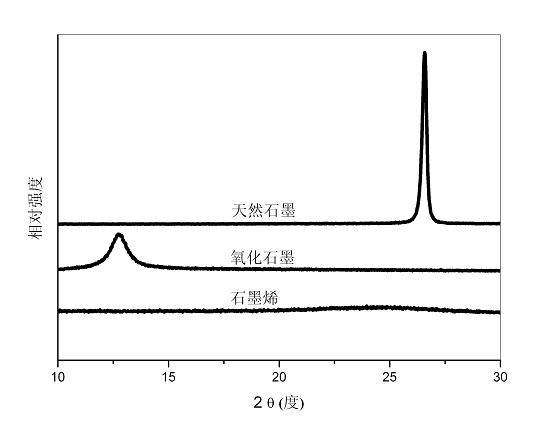

[0037] (1) Preparation of graphite oxide: take natural graphite powder as raw material, take 10g of natural graphite powder, add 220ml of 98% concentrated sulfuric acid, 5g of sodium nitrate, 30g of potassium permanganate in an ice bath, mechanically stir for 1 hour, and keep The temperature of the mixture is lower than 20°C. The ice bath was removed, and the mixture was stirred and reacted in a water bath at 35° C. for 4 hours, and then diluted with 500 ml of deionized water to obtain a suspension. Continue to react the suspension at 90°C for 15 minutes, add 600ml deionized water and 50ml hydrogen peroxide and react for 5 minutes to obtain a graphite oxide dilution. It was filtered while it was hot, washed with dilute hydrochloric acid solution to remove metal ions, washed with deionized water to remove excess acid, washed several times until neutral, and finally graphite oxide gel was obtained.

[0038] (2) Preparation of graphene oxide: dilute the graphite...

Embodiment 2

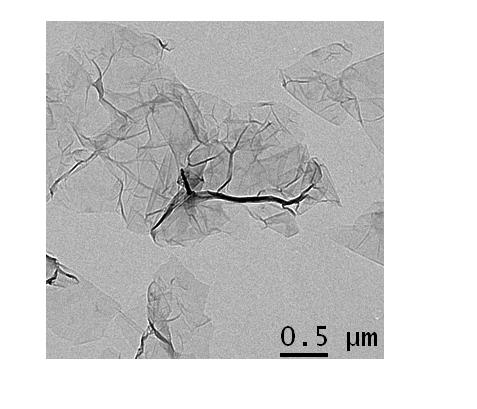

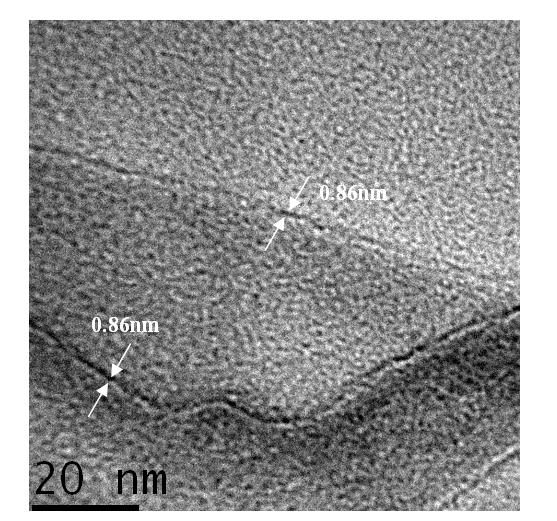

[0041] Get the monolayer graphene oxide dispersion liquid 500ml that embodiment 1 prepares, and 0.25g 3, the 4-dihydroxyphenylalanine reducing agent mixes uniformly, reflux reaction 24 hours under 90 ℃, magnetic stirring, filter, wash with water, obtain The black product is the single-layer graphene gel. Redisperse the single-layer graphene gel in water and / or organic solvent without adding any stabilizer to obtain a stable dispersion of single-layer graphene; vacuum-dry the single-layer graphene gel to obtain graphene powder . The single-layer graphene has a diameter of about 0.8 μm and a thickness of less than 1 nm.

Embodiment 3

[0043] (1) Preparation of graphite oxide: take natural graphite powder as raw material, take 10g of natural graphite powder, add 220ml of 98% concentrated sulfuric acid, 5g of sodium nitrate, 30g of potassium permanganate in an ice bath, mechanically stir for 1 hour, and keep The temperature of the mixture is lower than 20°C. The ice bath was removed, and the mixture was stirred and reacted in a water bath at 35° C. for 4 hours, and then diluted with 500 ml of deionized water to obtain a suspension. Continue to react the suspension at 90°C for 15 minutes, add 600ml deionized water and 50ml hydrogen peroxide and react for 5 minutes to obtain a graphite oxide dilution. It was filtered while it was hot, washed with dilute hydrochloric acid solution to remove metal ions, washed with deionized water to remove excess acid, washed several times until neutral, and finally graphite oxide gel was obtained.

[0044] (2) Preparation of graphene oxide: Dilute graphite oxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com