High-solubility multi-fold dry-state graphene oxide microsphere and preparation method thereof

A high-solubility, graphene microsphere technology, applied in the field of graphene materials, can solve problems that hinder industrialization and commercialization, affect the performance of graphene oxide, processability, and the existence of single-layer forms, and achieve good solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) dilute the graphene oxide dispersion prepared by Hummers method with dimethylformamide; the mass ratio of dimethylformamide and graphene oxide dispersion is 50:1;

[0031] (2) The dispersion liquid after step (1) is diluted, obtains graphene oxide microsphere by the method for atomization drying, and drying temperature is 130 ℃;

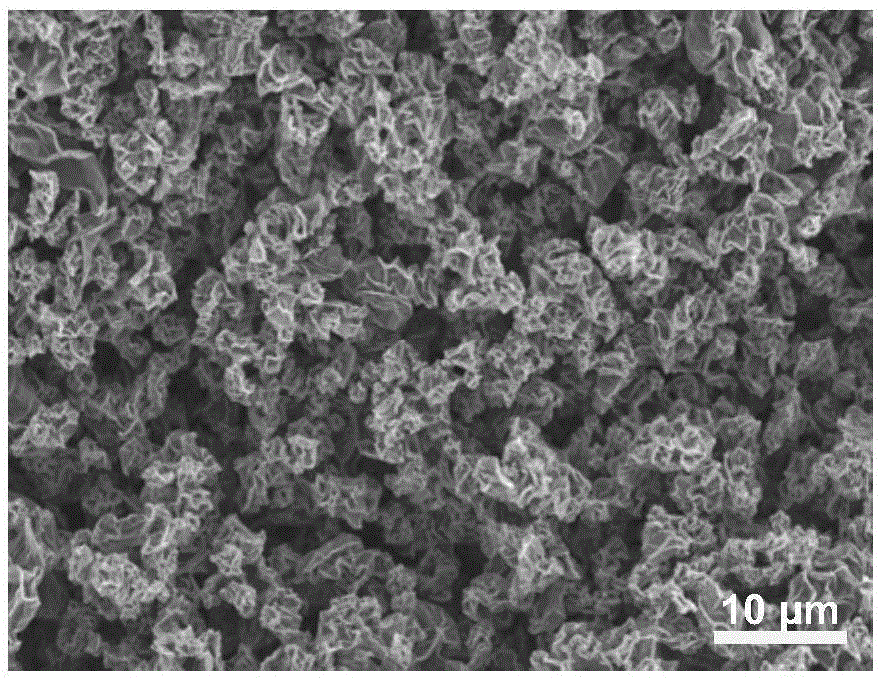

[0032] Through the above steps, the obtained multi-fold dry graphene oxide microspheres have a diameter of 500 nm to 30 μm, such as figure 1 , 2 shown. Its density is 0.1g / cm 3 , the specific surface area is 1400m 2 / g, the carbon-oxygen ratio is 2.3. Its solubility in water and common organic solvents is 30mg / g, and graphene oxide exists in the form of a single layer in the obtained dispersion, and can be dispersed stably for a long time (such as image 3 , 4 shown). The obtained dry graphene oxide powder is compressed into a block using a press, such as Figure 5 As shown, its density is 1.26g / cm 3 , can still be well dispersed....

Embodiment 2

[0034] (1) dilute the graphene oxide dispersion prepared by the Hummers method with ethanol; the mass ratio of ethanol to the graphene oxide dispersion is 1:1;

[0035] (2) The dispersion liquid after step (1) is diluted, obtains graphene oxide microsphere by the method for atomization drying, and drying temperature is 150 ℃;

[0036] After the above steps, the obtained multi-fold dry graphene oxide microspheres have a diameter of 500nm-30μm and a density of 0.13g / cm 3 , the specific surface area is 800m 2 / g, the carbon-oxygen ratio is 2.6. Its solubility in water and common organic solvents is 20mg / g, and the graphene oxide in the obtained dispersion exists in the form of a single layer, and can be dispersed stably for a long time.

Embodiment 3

[0038] (1) dilute the graphene oxide dispersion prepared by the Hummers method with methanol; the mass ratio of methanol to the graphene oxide dispersion is 5:1;

[0039](2) The dispersion liquid after step (1) is diluted, obtains graphene oxide microsphere by the method for atomization drying, and drying temperature is 125 ℃;

[0040] After the above steps, the obtained multi-fold dry graphene oxide microspheres have a diameter of 500nm-30μm and a density of 0.09g / cm 3 , the specific surface area is 710m 2 / g, the carbon-oxygen ratio is 2.1. Its solubility in water and common organic solvents is 20mg / g, and the graphene oxide in the obtained dispersion exists in the form of a single layer, and can be dispersed stably for a long time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Carbon to oxygen ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com