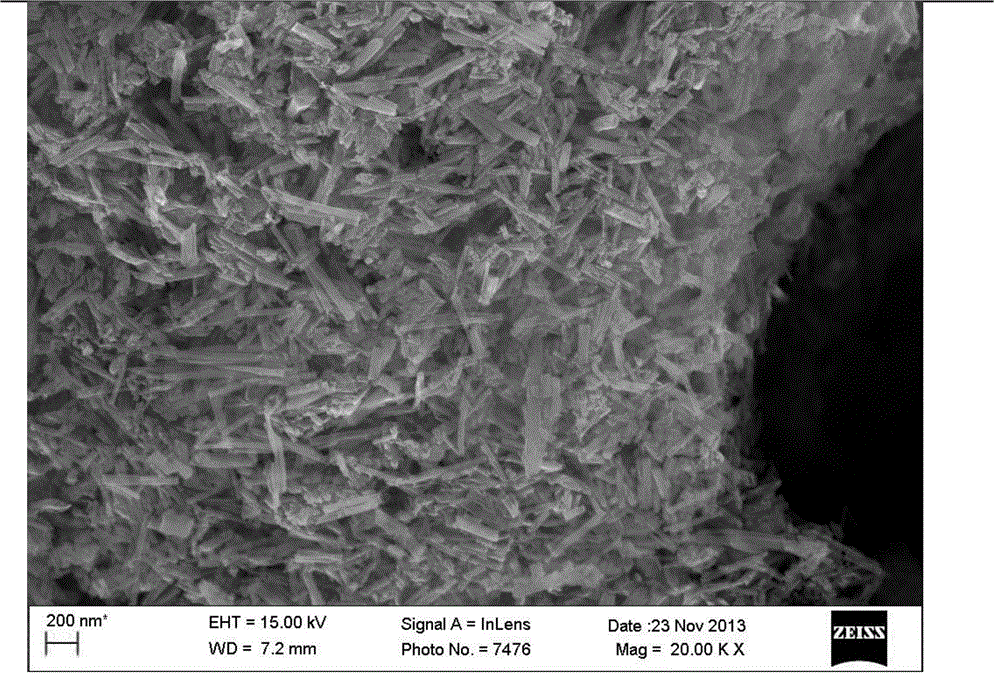

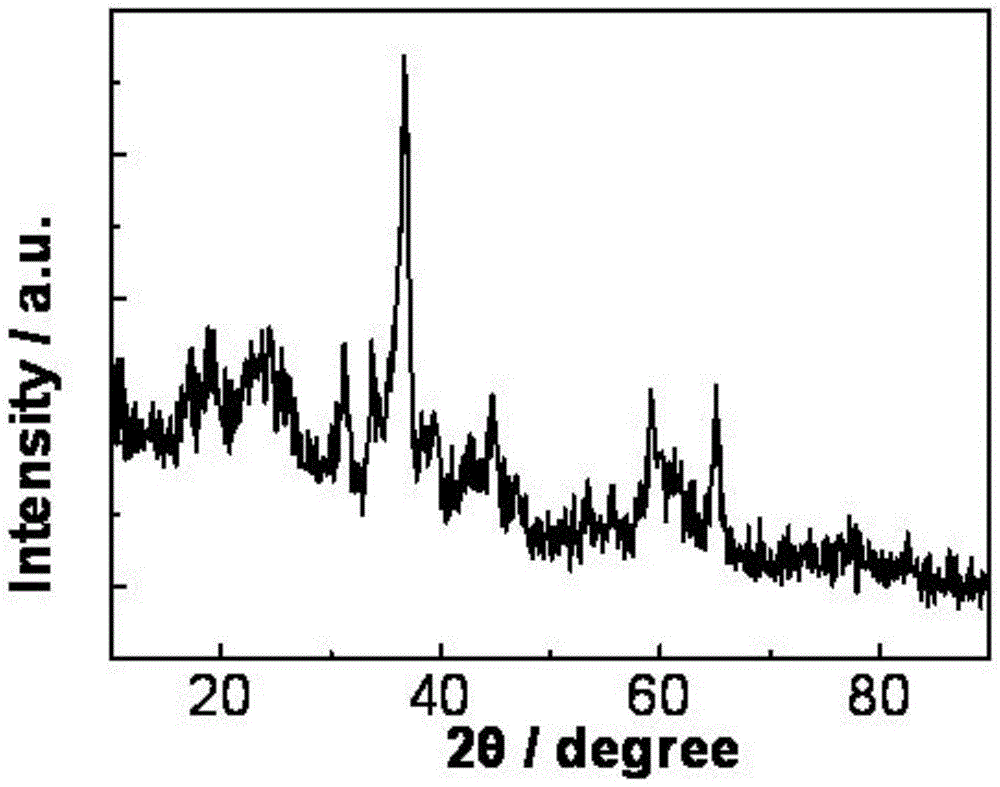

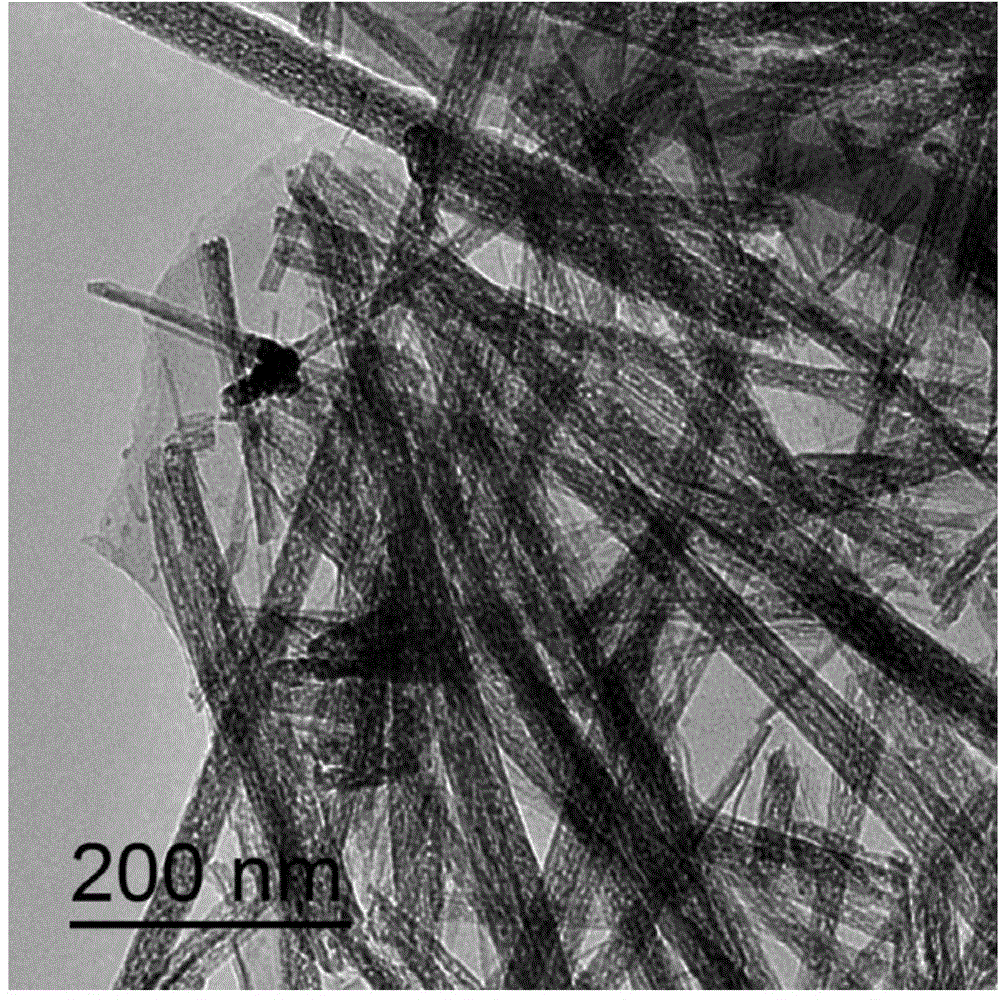

Graphene in-situ load needle-shaped Co3O4 composite electrode material and manufacturing method thereof

A composite electrode and graphene technology, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, can solve the problems of poor cycle performance and poor conductivity, and achieve the effect of improving cycle life and good electrochemical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Preparation of graphene oxide

[0034] With 5.0g natural graphite powder, 5.0g potassium persulfate (K 2 S 2 o 8 ) and 10.0g phosphorus pentoxide (P 2 o 5 ) into 33mL of concentrated sulfuric acid in sequence, and kept at 80°C for 6h; cooled to room temperature, diluted with deionized water, filtered and washed until the pH was 7, and then vacuum-dried at 80°C overnight. Weigh pre-oxidized graphite 2.5g, potassium permanganate (KMnO 4 ) 7.5g into 40mL concentrated sulfuric acid at 0°C in turn, first keep warm at below 20°C for 2.5h, keep stirring at about 35°C for 3.5h, then add about 80mL of deionized water, keep stirring at 95°C for 1.5h, and finally add the weight percentage 30%H 2 o 2 After reacting for half an hour, it was observed that the color of the mixed solution turned bright yellow, indicating that the reaction was complete. The above mixture was filtered and washed three times with dilute hydrochloric acid with a mass fraction of 10% to remove m...

Embodiment 2

[0040] (1) Preparation of graphene oxide

[0041] With 5.0g natural graphite powder, 15.0g potassium persulfate (K 2 S 2 o 8 ) and 5.0g phosphorus pentoxide (P 2 o 5 ) into 32mL of concentrated sulfuric acid in turn, and kept at 60°C for 7h; cooled to room temperature, diluted with deionized water, filtered and washed until the pH was 7, and then vacuum-dried at 80°C overnight. Weigh pre-oxidized graphite 2.5g, potassium permanganate (KMnO 4 ) 15g into 85mL of concentrated sulfuric acid at 0°C in turn, first keep warm at 5°C for 2.5h, then keep warm at about 35°C for 2h, then add about 170mL of deionized water, keep warm at 95°C for 1.5h, and finally add 30% by weight h 2 o 2 After reacting for half an hour, it was observed that the color of the mixed solution turned bright yellow, and the reaction was completed at this time. The above mixture was filtered and washed three times with dilute hydrochloric acid with a mass fraction of 15% to remove metal ions; then washed...

Embodiment 3

[0046] (1) Preparation of graphene oxide

[0047] With 5.0g natural graphite powder, 10.0g potassium persulfate (K 2 S 2 o 8 ) and 5.0g phosphorus pentoxide (P 2 o 5 ) into 25 mL of concentrated sulfuric acid in sequence, and kept at 85°C for 4h; cooled to room temperature, diluted with deionized water, filtered and washed until the pH was 7, and then vacuum-dried at 80°C overnight. Weigh pre-oxidized graphite 2.5g, potassium permanganate (KMnO 4 ) 7.5g was added to 115mL concentrated sulfuric acid at 0°C in turn, first kept at 18°C for 1h, then stirred at 35°C for 2h, then added about 230mL of deionized water, kept at 95°C for 1.5h, and finally added 30% H by weight 2 o 2 until the reaction is complete. The above mixture was filtered and washed three times with dilute hydrochloric acid with a mass fraction of 10% to remove metal ions; then washed three times with deionized water to remove excess acid; then dispersed in 800mL deionized water and ultrasonically treated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com