Method for preparing graphene/semiconductor quantum dot composite material

A composite material and quantum dot technology, which is applied in the field of preparing graphene/semiconductor quantum dot composite materials, can solve the problems of poor repeatability of the synthesis process, complicated preparation process, and high cost, and achieve low toxicity, simple preparation process, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

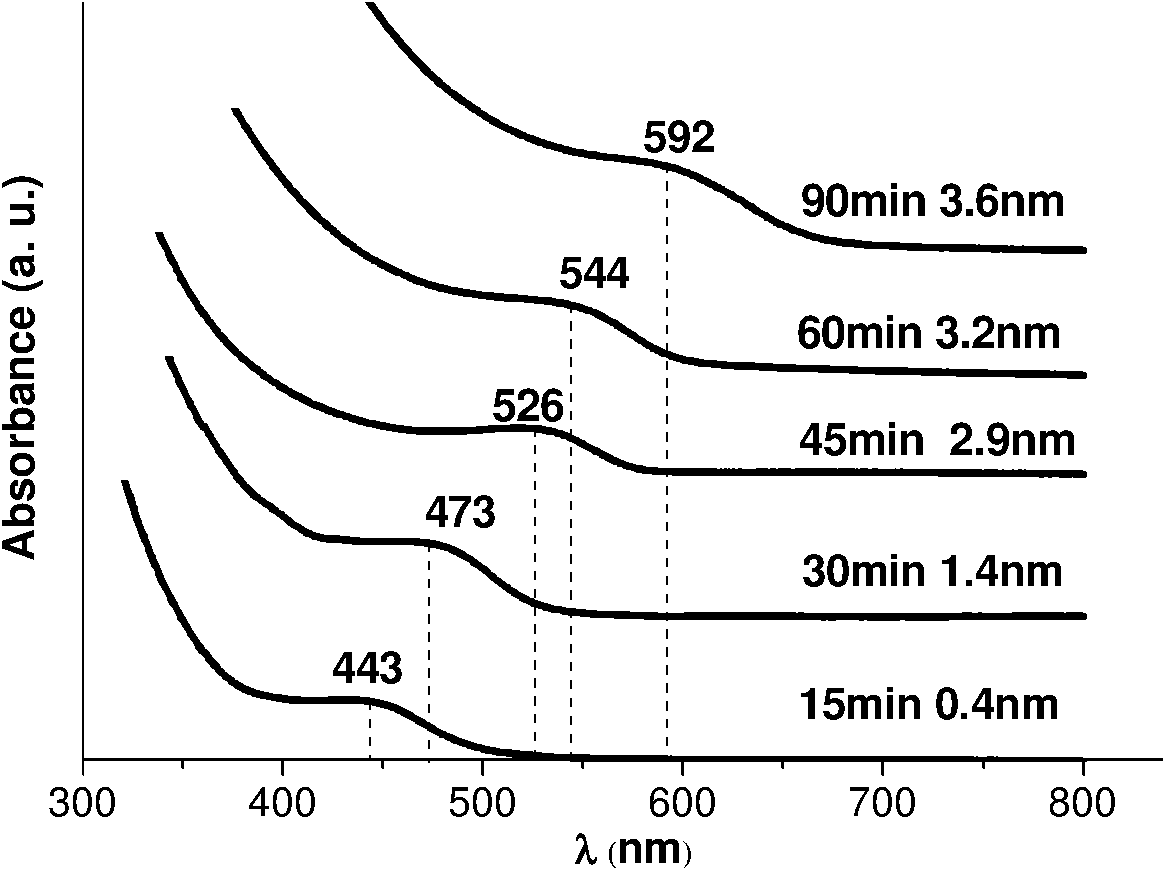

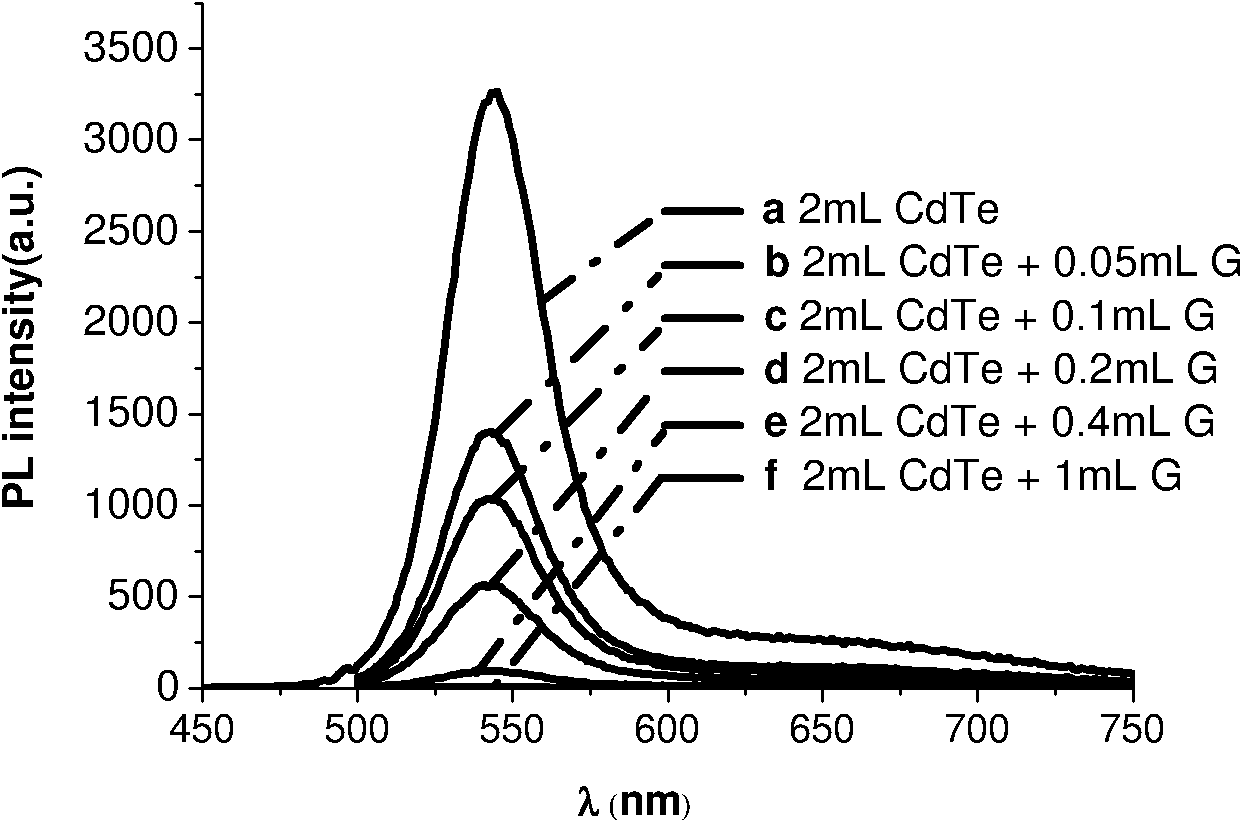

[0032] Prepare graphene / CdTe quantum dot composite material, comprising the following steps:

[0033] 1) Put 2g of natural graphite powder with a particle size of 500 mesh and 1g of sodium nitrate in a 250ml three-necked bottle, and cool it to 0°C in an ice bath; slowly add 50mL of concentrated sulfuric acid into the three-necked bottle, and fully stir for 30 minutes to ensure the stability of the reaction system. The temperature is not higher than 5°C; add 0.3g of potassium permanganate into the there-necked flask, and fully stir for 30 minutes, while ensuring that the temperature of the reaction system is not higher than 10°C; within 1 hour, divide 7g of potassium permanganate into 3 Add batches into the three-necked flask to ensure that the temperature of the reaction system is not higher than 20°C; remove the ice bath and replace it with a water bath to heat the temperature of the reaction system to 35±3°C, stir and react for 2 hours to obtain a brown graphite suspension; r...

Embodiment 2

[0038] Prepare graphene / CdTe quantum dot composite material, comprising the following steps:

[0039] Steps 1) and 2) in this embodiment are exactly the same as those in the above embodiment. The difference is that in step 3), the bright yellow CdTe quantum dot precursor solution obtained in 2) is mixed with the graphene solution in 1), and then transferred to an autoclave for heat treatment at 160°C for 30 minutes. bit to generate CdTe quantum dots.

Embodiment 3

[0041] Prepare graphene / HgSe quantum dot composite material, comprising the following steps:

[0042] 1) is exactly the same as 1) in the above-mentioned embodiment 1.

[0043] 2) Take 0.94g (2.35mmol) Hg (ClO 4 ) 2 , 250mL of water, and 502μL (5.77mmol) of mercaptopropionic acid were placed in a three-necked flask. The solution appeared turbid. The pH value of the system was adjusted to 11.2 with 1M NaOH solution, and the solution became clear. The solution was continuously passed through nitrogen for 30 minutes to remove the air, and keep the system in a nitrogen atmosphere for use; take 0.186g Se powder and place it in a nitrogen-filled reagent bottle, and quickly inject 0.178g NaBH into it 4 and 10mL water until the black Se powder disappears to obtain a transparent NaHSe aqueous solution; the NaHSe aqueous solution is magnetically stirred and passed through N 2 Under the condition of fast injection in the three-necked bottle filled with Hg salt solution, the molar rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com