Method for simply and innoxiously preparing single-layer graphene

A single-layer graphene and graphite technology, applied in the field of inorganic material chemistry, can solve problems such as high cost, long preparation time, and complicated process, and achieve the effects of environmental protection, low manufacturing cost, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The preparation process and steps in this embodiment are as follows:

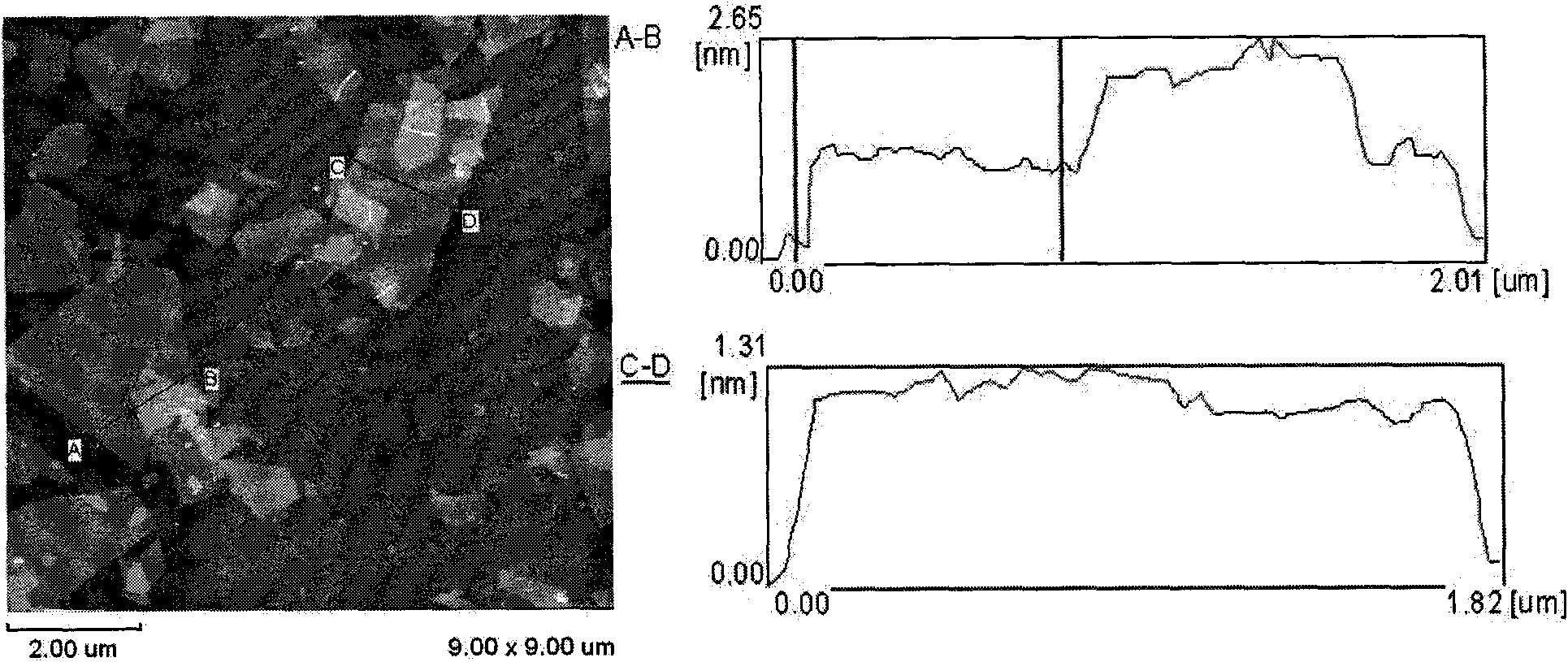

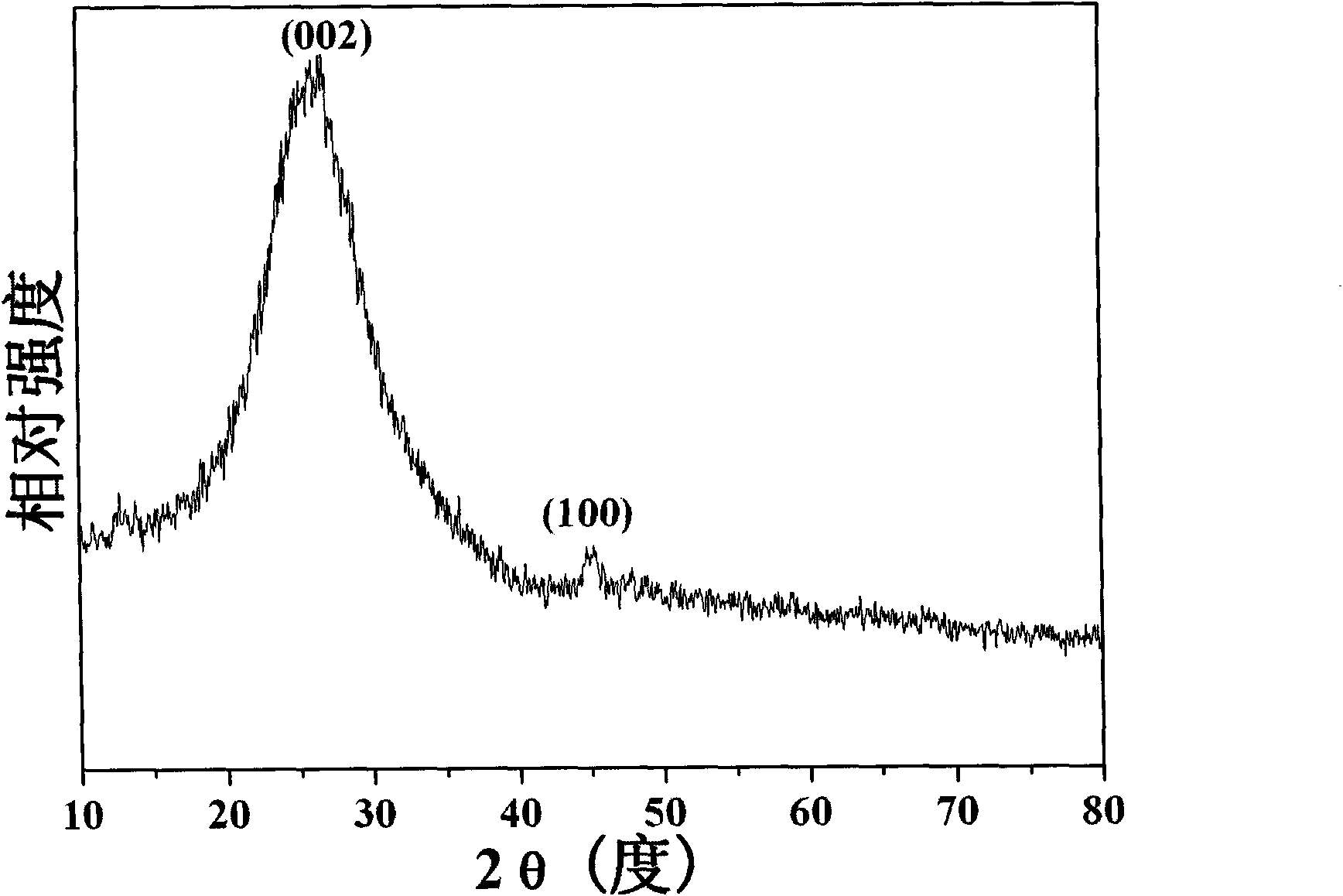

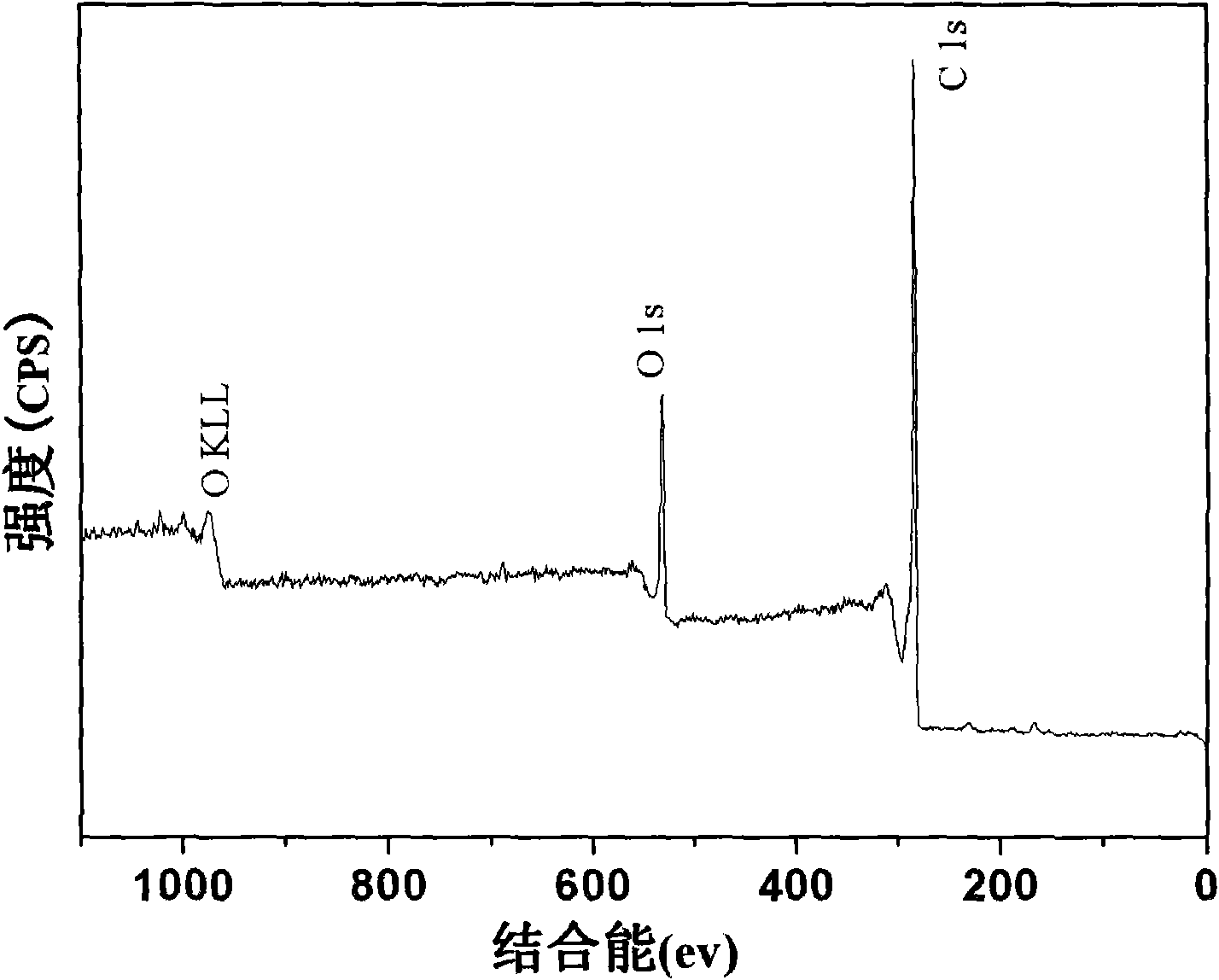

[0016] 1. Preparation of single-layer graphite oxide sheet solution and graphene oxide solid: use natural graphite powder as raw material, get 3 grams of natural graphite powder with a fineness of 325 meshes, add 12 milliliters of concentrated sulfuric acid, 2.5 grams of potassium persulfate and 2.5 grams of Phosphorus pentoxide, uniformly mixed at 80°C, allowed to react for 4.5 hours; the mixture was cooled to room temperature, diluted with deionized water and allowed to stand overnight, then separated by filtration with a cellulose acetate membrane with 0.2 micron pores, and washed with a large amount of Washed with deionized water, the product was left standing overnight at room temperature; the above product, namely pre-oxidized graphite, was stirred and slowly added to a mixed solution of 120 milliliters of cooled concentrated sulfuric acid at 0°C and 15 grams of potassium permanganate. After st...

Embodiment 2

[0019] The preparation process and steps in this example are exactly the same as those in Example 1 above. The difference is: the heating temperature in the reactor is 150°C, the reaction time is 10 hours, and finally the single-layer graphene is produced.

Embodiment 3

[0021] The preparation process and steps in this example are exactly the same as those in Example 1 above. The difference is: the heating temperature in the reactor is 200°C, the reaction time is 16 hours, and finally a single-layer graphene is produced

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com