Graphene oxide modified water-based epoxy anticorrosive paint

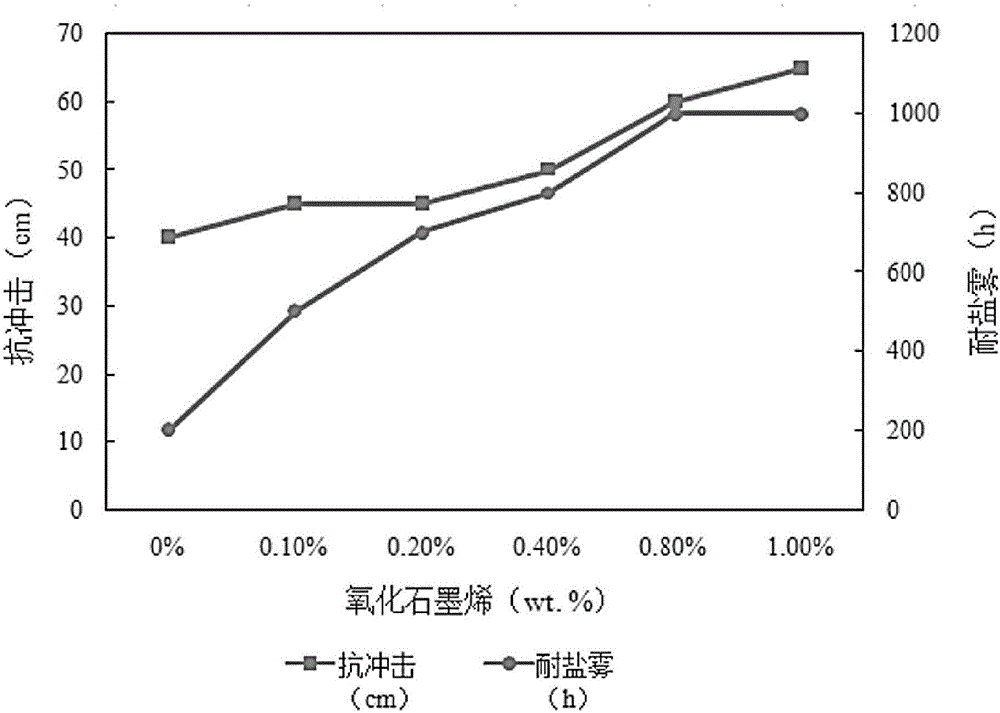

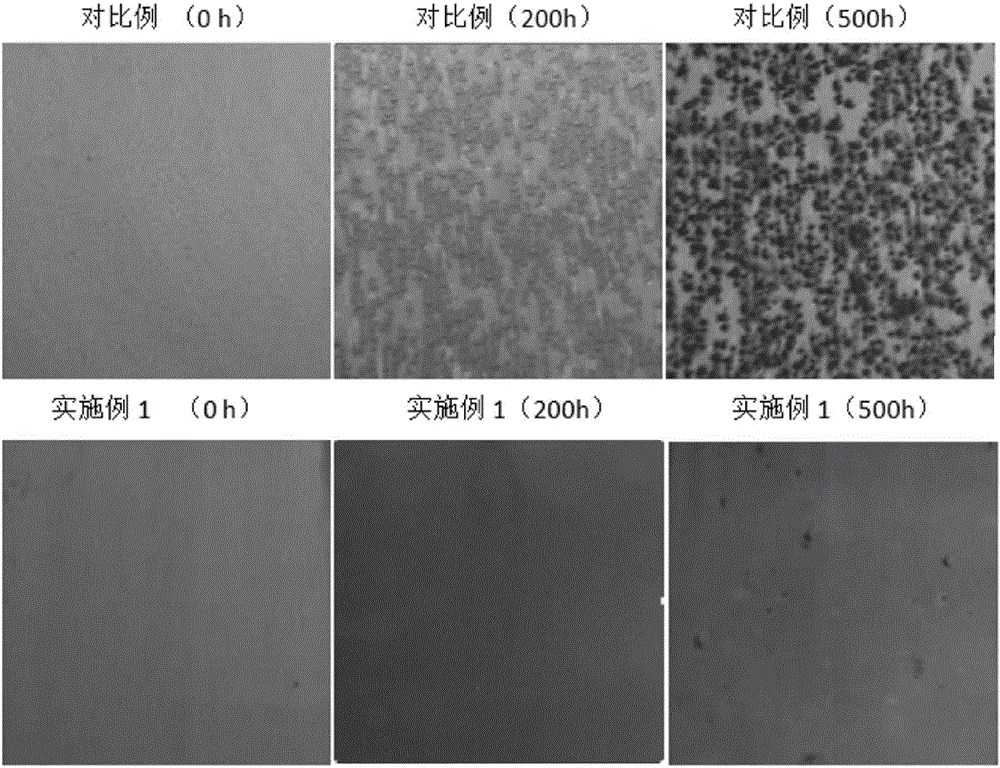

A graphene-modified, water-based epoxy technology, which is applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of easy agglomeration of single-layer graphene oxide, decreased wet adhesion of coatings, and failure to meet the size requirements, etc. problem, to achieve the effects of short dispersion time, reduced impact, improved corrosion resistance and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following examples relate to the method for preparing the above-mentioned graphene-modified water-based epoxy anticorrosion paint, specifically comprising the following steps:

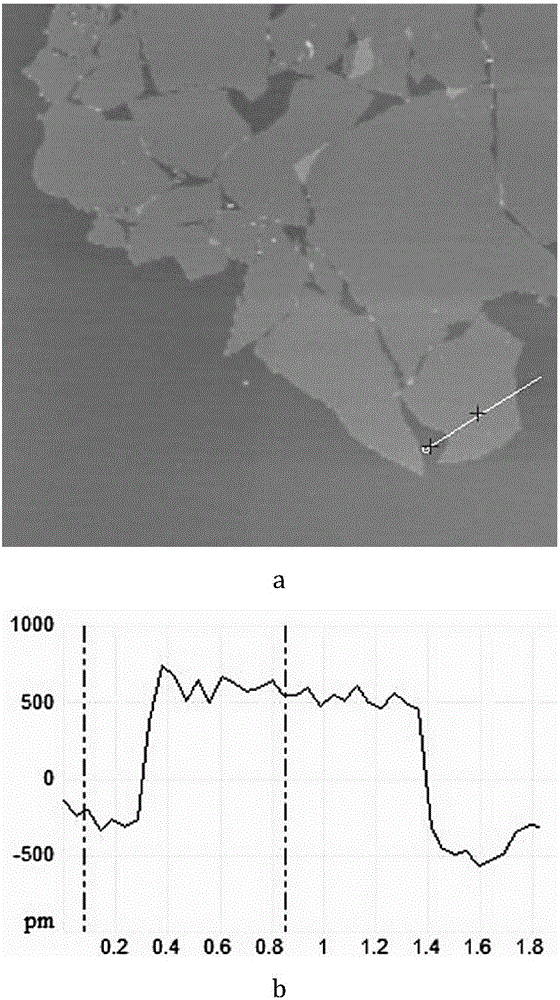

[0032] Step 1: Disperse single-layer graphene oxide in deionized water: add deionized water to the graphene oxide slurry or powder, ultrasonically stir and disperse for 20 minutes.

[0033] Step 2: Mix the water-based epoxy resin composite formula in proportion and disperse with high-speed stirring until the fineness is less than 30 μm.

[0034] Step 3: Mix the dispersed water-based epoxy resin compound formula with the water-based epoxy resin curing agent and use it up within 4 hours.

[0035] The waterborne epoxy resin composite formula in this embodiment is made up of the following raw materials in parts by weight: 0.2 parts of coupling agent, 0.3 parts of wetting and dispersing agent, 33 parts of fillers (wherein wollastonite powder accounts for 18 parts, mica powder accounts for 3 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com